Efficient environment-friendly reactive extrusion integrated continuous processing technology of urea aldehyde and derivatives thereof

A technology of reactive extrusion and processing technology, applied in the field of high-efficiency and environmentally friendly reactive extrusion integrated continuous processing technology, to achieve the effects of significant economic and social benefits, flexible nutrient composition and content, and short payback period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

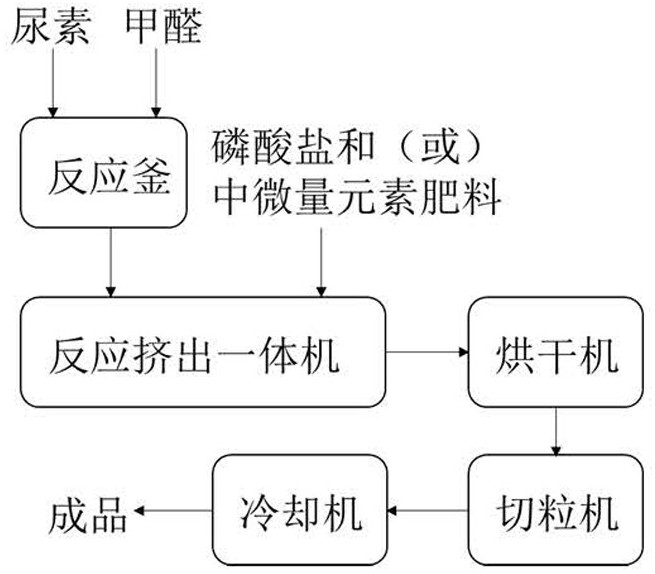

Method used

Image

Examples

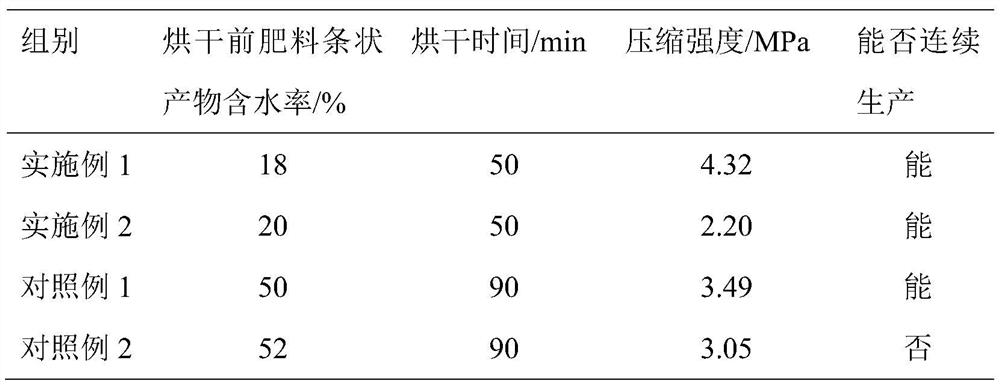

Embodiment 1

[0035] An efficient and environmentally friendly reactive extrusion integrated continuous processing process for preparing urea aldehyde derivatives, comprising the following steps:

[0036] (1) Add 5000g of formaldehyde into the reactor, then add 1920g of urea, react at 80°C for 30min, and obtain a methylol urea solution.

[0037] (2) Seal the die mouth of the integrated reaction extrusion machine, then add the above-mentioned methylol urea solution into the integrated reaction extrusion machine, and then add 50 g of hydroxyapatite.

[0038] (3) Set the temperature of the reaction unit of the reaction extrusion machine to 100°C, adjust the rotation speed of the stirring shaft to 50r / min for the reaction, and start the vacuum devolatilization unit to remove the moisture in the reaction system at the same time, the vacuum degree is -0.07MPa, until the reaction system becomes viscous.

[0039] (4) Open the die mouth of the integrated reaction extrusion machine, start the extrus...

Embodiment 2

[0042] An efficient and environmentally friendly reactive extrusion integrated continuous processing process for preparing urea aldehyde, comprising the following steps:

[0043] (1) Add 5000g of formaldehyde into the reactor, then add 1920g of urea, react at 80°C for 30min, and obtain a methylol urea solution.

[0044] (2) Seal the die mouth of the integrated reaction extrusion machine, and then add the above-mentioned methylol urea solution into the integrated reaction extrusion machine.

[0045] (3) Set the temperature of the reaction unit of the reaction extrusion machine to 100°C, adjust the rotation speed of the stirring shaft to 50r / min for the reaction, and start the vacuum devolatilization unit to remove the moisture in the reaction system at the same time, the vacuum degree is -0.07MPa, until the reaction system becomes viscous.

[0046] (4) Open the die mouth of the integrated reaction extrusion machine, start the extrusion unit of the integrated reaction extrusion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com