Method for preparing sodium-ion battery negative electrode material antimony sulfide from high-arsenic-antimony soot

A sodium-ion battery, high-arsenic antimony soot technology, applied in the direction of antimony sulfide, chemical instruments and methods, antimony compounds, etc., can solve the problem of losing valuable metals, and achieve the effect of avoiding the recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

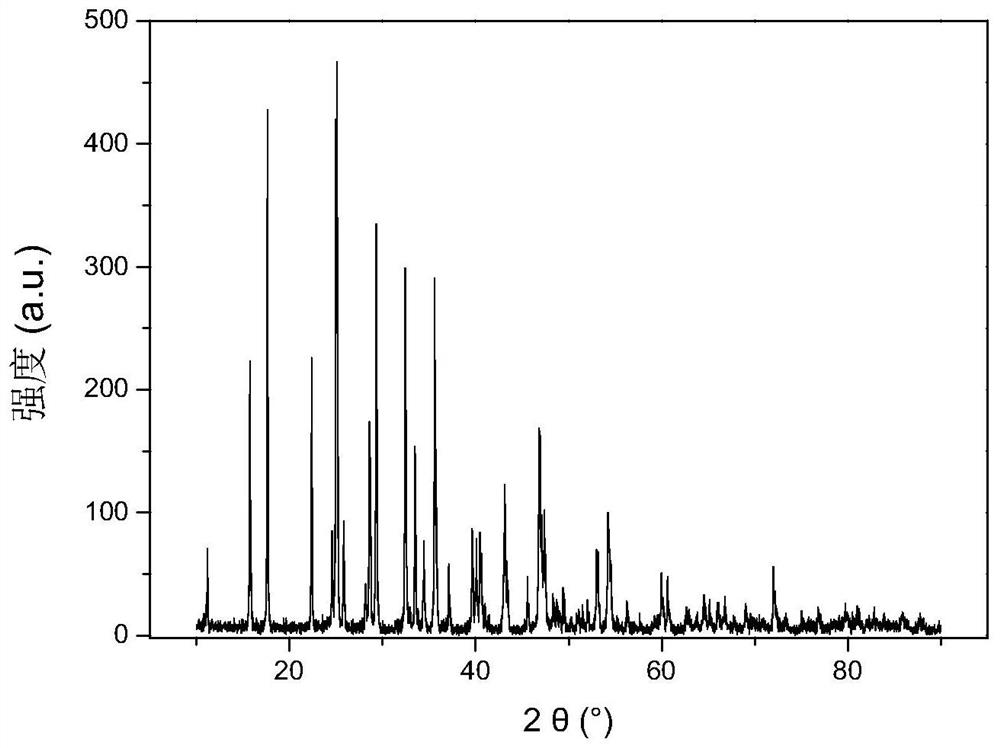

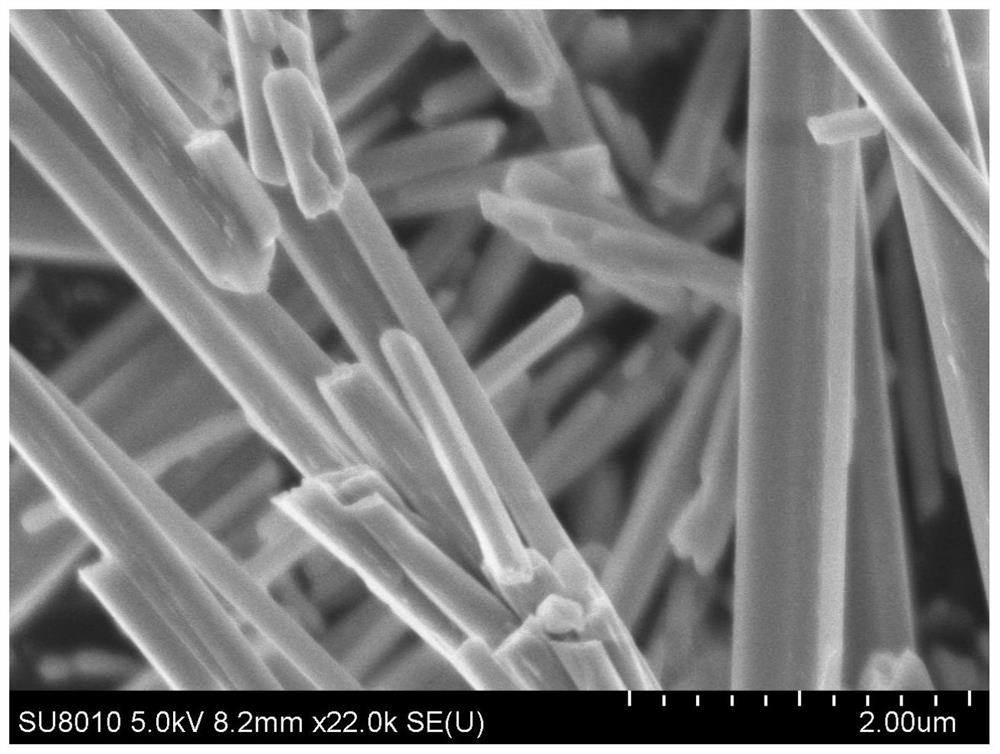

[0023] Add 5g of high-arsenic and antimony soot into an autoclave equipped with 50mL of 4mol / L NaOH solution, adjust the oxygen pressure by blowing oxygen, and filter to obtain the filter residue after the reaction is complete; after washing with water several times, use 2mol / L H 2 SO 4 solution to dissolve it, and detect the specific ion concentration (removal rate of As and Sb 3+ concentration in the solution); according to the molar ratio of Sb:S=1:2, add thiourea to the solution, stir evenly and then transfer to the autoclave; the hydrothermal temperature is controlled at 180°C, and the hydrothermal time is controlled at 80min , After the reaction is over, wash the product with alcohol several times and dry it at 80°C.

[0024] Weigh 0.07g of the above-prepared product, 0.02g of acetylene black (conductive agent), 0.01g of PVDF (HSV900, binder), and add an appropriate amount of NMP solution after fully grinding. , after vacuum drying at 120°C, cut into discs with a diame...

Embodiment 2

[0028] Add 5g of high arsenic and antimony soot into an autoclave equipped with 50mL of 5mol / L NaOH solution, adjust the oxygen pressure by blowing oxygen, and filter to obtain the filter residue after the reaction is complete; after washing with water for many times, use 3mol / L H 2 SO 4 solution to dissolve it, and detect the specific ion concentration (removal rate of As and Sb 3+ concentration in the solution); according to the molar ratio of Sb:S=1:2.5, add thiourea to the solution, stir evenly and then transfer to the autoclave; the hydrothermal temperature is controlled at 160°C, and the hydrothermal time is controlled at 100min , After the reaction is over, wash the product with alcohol several times and dry it at 80°C.

[0029] Weigh 0.07g of the above-prepared product, 0.02g of acetylene black (conductive agent), 0.01g of PVDF (HSV900, binder), and add an appropriate amount of NMP solution after fully grinding. , after vacuum drying at 120°C, cut into discs with a d...

Embodiment 3

[0031] Add 5g of high-arsenic and antimony soot into an autoclave equipped with 50mL of 6mol / L NaOH solution, adjust the oxygen pressure by blowing oxygen, and filter to obtain the filter residue after the reaction is complete; 2 SO 4 solution to dissolve it, and detect the specific ion concentration (removal rate of As and Sb 3+ Concentration in the solution); according to the molar ratio of Sb:S=1:3, add thiourea to the solution, stir evenly and transfer to the autoclave; the hydrothermal temperature is controlled at 140°C, and the hydrothermal time is controlled at 120min , After the reaction is over, wash the product with alcohol several times and dry it at 80°C.

[0032] Weigh 0.07g of the above-prepared product, 0.02g of acetylene black (conductive agent), 0.01g of PVDF (HSV900, binder), and add an appropriate amount of NMP solution after fully grinding. , after vacuum drying at 120°C, cut into discs with a diameter of 12 mm, and assemble them in a glove box with an ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com