Numerical control turning machining center system and operation method thereof

A machining center and turning technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problems of blocked translation of nut pairs, high cleaning costs, waste of screw rods, etc., to achieve smooth translation and reduce maintenance Low cost, smooth and unimpeded rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

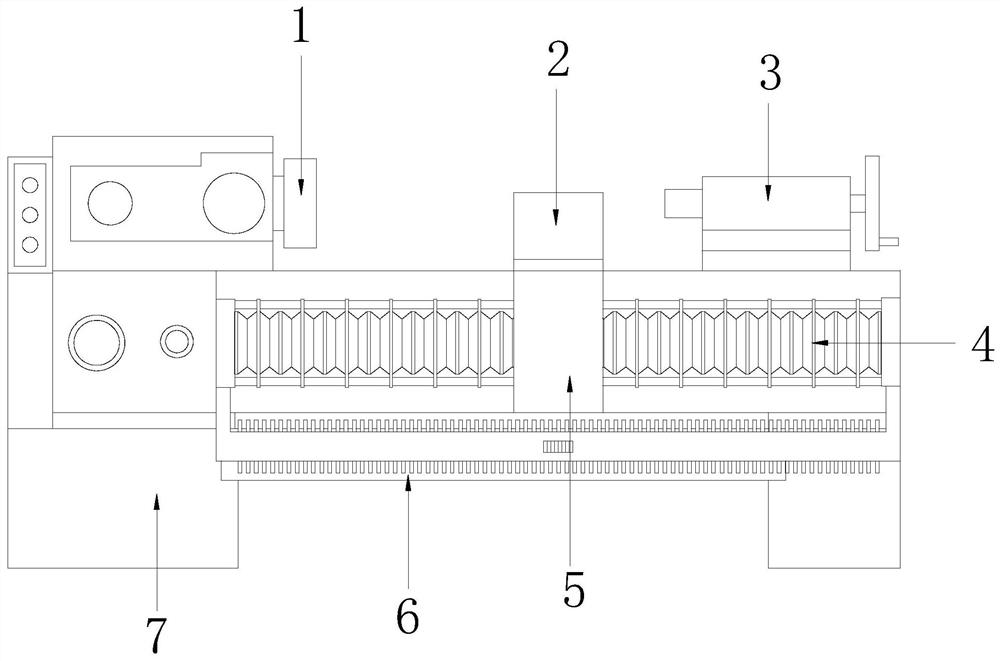

[0034] see figure 1 , the present invention provides a numerically controlled turning machining center system and its operating method technical scheme: its structure includes a fixed chuck 1, a turning device 2, a moving clamp device 3, a moving device 4, a moving seat 5, a water tray 6, and a machine body 7 , one side of the body 7 is provided with a fixed chuck 1, and the other side is equipped with a movable clamp device 3, and a turning device 2 is arranged between the fixed chuck 1 and the movable clamp device 3, and the turning device 2 is connected to the mobile The seat 5 is connected, the mobile seat 5 is connected to the mobile device 4, the mobile device 4 is connected to the body 7, and the body 7 is also equipped with a water receiving tray 6;

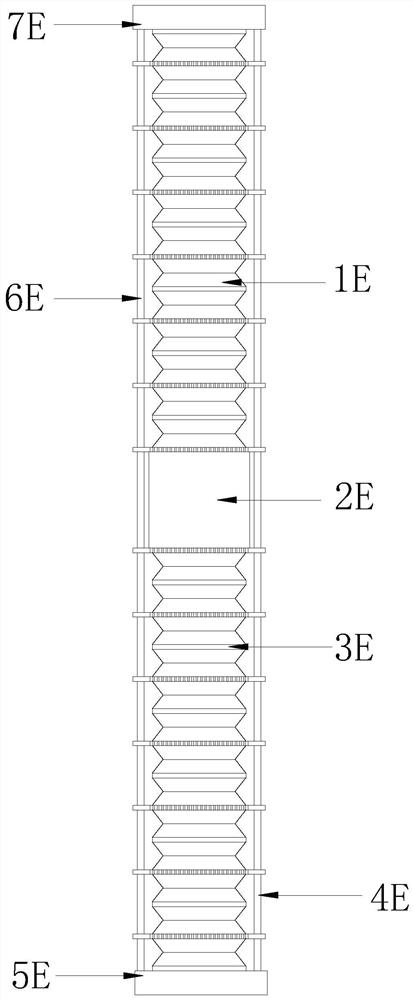

[0035] see Figure 2-5 , the moving device 4 includes a No. 1 bellows 1E, a nut pair 2E, a No. 2 bellows 3E, a No. 1 guide rod 4E, a No. 2 fixing seat 5E, a No. 2 guide rod 6E, a No. 1 fixing seat 7E, and a screw rod 8E...

Embodiment 2

[0038] see figure 1 , the present invention provides a numerically controlled turning machining center system and its operating method technical scheme: its structure includes a fixed chuck 1, a turning device 2, a moving clamp device 3, a moving device 4, a moving seat 5, a water tray 6, and a machine body 7 , one side of the body 7 is provided with a fixed chuck 1, and the other side is equipped with a movable clamp device 3, and a turning device 2 is arranged between the fixed chuck 1 and the movable clamp device 3, and the turning device 2 is connected to the mobile The seat 5 is connected, the mobile seat 5 is connected to the mobile device 4, the mobile device 4 is connected to the body 7, and the body 7 is also equipped with a water receiving tray 6;

[0039] see Figure 2-5 , the moving device 4 includes a No. 1 bellows 1E, a nut pair 2E, a No. 2 bellows 3E, a No. 1 guide rod 4E, a No. 2 fixing seat 5E, a No. 2 guide rod 6E, a No. 1 fixing seat 7E, and a screw rod 8E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com