Winding device for armored platinum-rhodium wire production

A technology of winding device and platinum rhodium wire, which is applied in the directions of transportation and packaging, cleaning methods and utensils, and delivery of filamentous materials, to achieve the effects of ensuring normal operation, improving reliability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

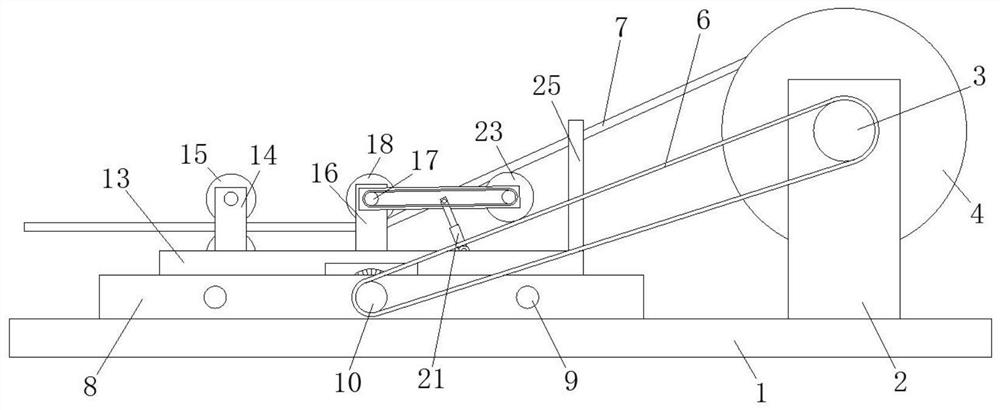

[0029] refer to Figure 1-5 , a winding device for armored platinum-rhodium wire production, comprising a base 1, the rear side of the top of the base 1 is fixedly connected with a winding mechanism, the right side of the winding mechanism is provided with a first belt 6, and the first belt 6 is connected in rotation There is a reciprocating translation mechanism, the top of the reciprocating translation mechanism is provided with a support plate 13, the top of the support plate 13 is provided with a deburring mechanism, and the rear side and left and right sides of the top of the support plate 13 are provided with foreign matter blocking mechanisms;

[0030] The reciprocating translation mechanism is driven by the winding mechanism to move at the same time, and the platinum-rhodium wire 7 is stacked while being wound. At the same time, the deburring mechanism performs surface treatment on the platinum-rhodium wire 7, and the foreign matter blocking mechanism prevents the remov...

Embodiment 2

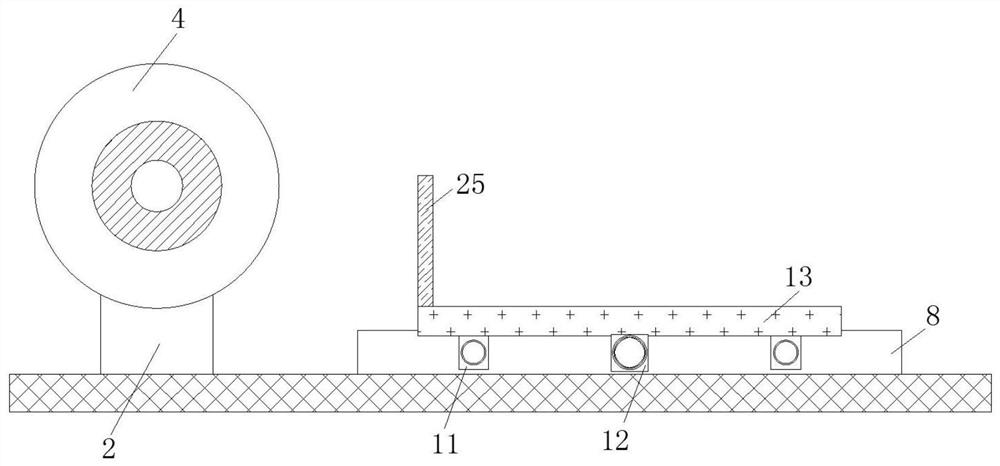

[0035] Such as Figure 1-5As shown, this embodiment is basically the same as Embodiment 1. Preferably, the reciprocating translation mechanism includes two second mounting plates 8 fixedly connected to the top of the base 1, and two sliding rods 9 are rotatably connected between the two second mounting plates 8. Two-way threaded rods 10 are rotatably connected between the two second mounting plates 8, and the two-way threaded rods 10 are rotatably connected to the midpoint of the second mounting plates 8. 9. A slide block 11 is slidably connected, and the two-way threaded rod 10 is engaged with a threaded sleeve 12. The threaded sleeve 12 is fixedly connected to the midpoint of the bottom of the supporting plate 13, and the sliding block 11 is fixedly connected to the four corners of the bottom of the supporting plate 13;

[0036] The winding mechanism includes two first mounting plates 2 fixedly mounted on the rear side of the top of the base 1, a first rotating shaft 3 is ro...

Embodiment 3

[0039] Such as Figure 1-5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the first belt 6 is rotatably sleeved on the right end of the bidirectional threaded rod 10 .

[0040] In this embodiment, the connection of the first belt 6 makes the first rotating shaft 3 and the two-way threaded rod 10 rotate at the same time, so as to ensure the synchronization of the support plate 13 moving left and right for stacking when the winding roller 4 winds the platinum-rhodium wire 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com