Technology and structure of fused light composite epoxy resin on the surface of inner crown

A body surface and composite ring technology, which is applied in dentistry, protective layer, filling teeth, etc., can solve problems such as poor strength and peeling of crowns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Please refer to the following detailed description and drawings of the present invention to further understand the characteristics and technical content of the present invention. However, the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

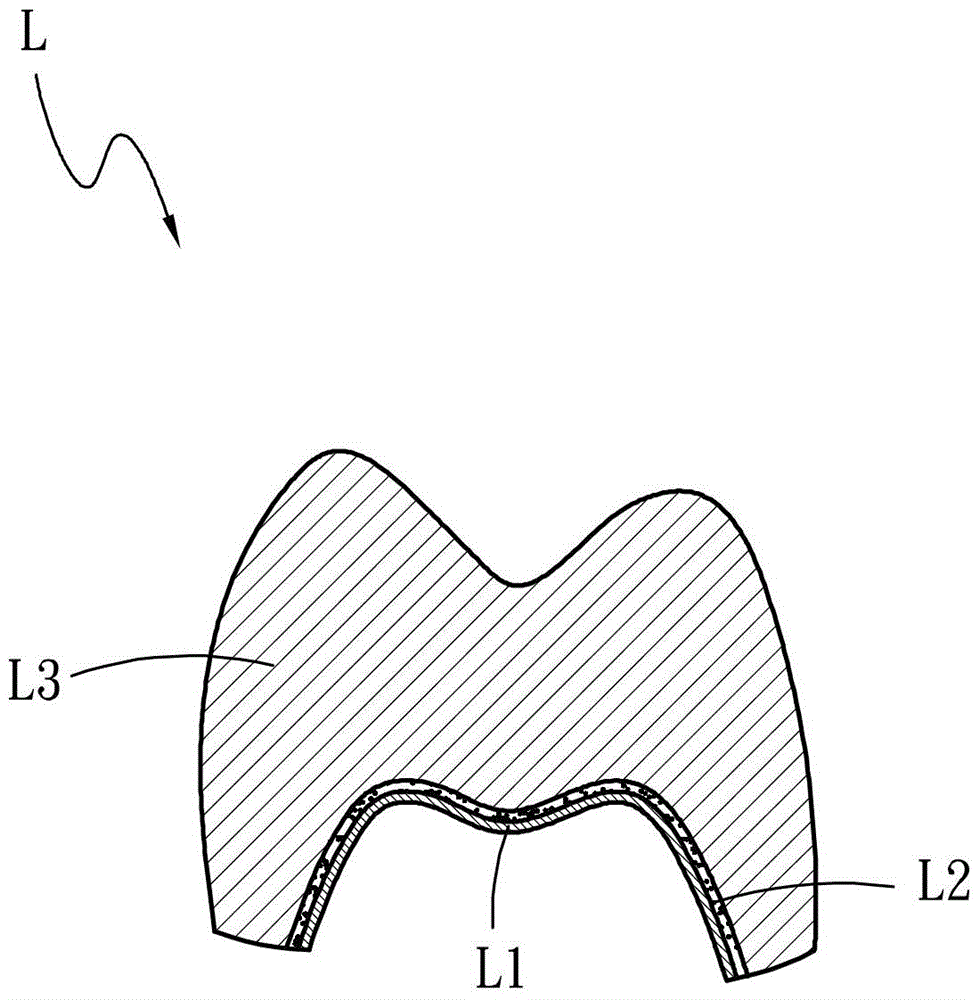

[0061] A kind of crown body structure L of the present invention, such as figure 1 As shown, it includes an inner crown body L1 made of zirconia material or a metal material for sintered porcelain teeth, a light composite epoxy resin layer L2 and an outer crown body L3, wherein the The irradiated composite epoxy resin layer L2 is connected to the upper part of the inner dental crown L1, and the outer dental crown L3 is connected to the upper part of the irradiated composite epoxy resin layer L2. Therefore, the dental crown structure L is The light composite epoxy resin layer L2 is used as an adhesive interlayer to combine the inner crown body L1 and the outer crown body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com