A kind of technical method of installing meson on metal lamp tube

A technology of metal lamp tubes and process methods, which is applied to the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of complex surface polishing process of metal lamp tubes, long time of welding surface treatment, high processing waste rate, etc., to achieve The effect of beautiful appearance decoration, shortened surface treatment time and low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

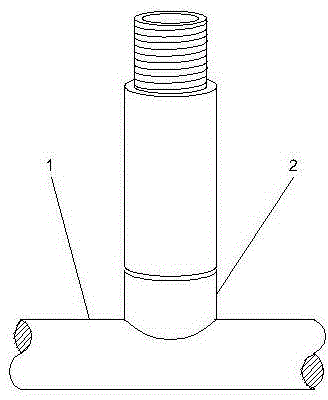

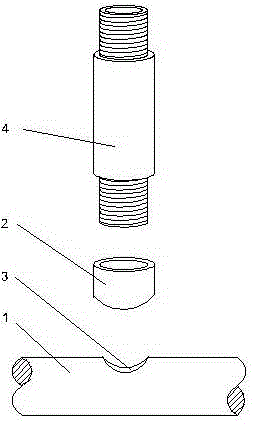

[0016] see Figure 1~Figure 4 , the figure shows the structure of the metal lamp tube 1 on which the meson 1 is installed according to the present invention. The present invention will be further described below in conjunction with the accompanying drawings.

[0017] A process method for installing a meson 2 on a metal lamp tube 1, comprising the following steps:

[0018] (1) Drill a tube hole 3 with a diameter of 3 mm to 5 mm at the position where the meson 2 needs to be installed on the metal lamp tube 1;

[0019] (2) Reaming the tube hole 3 with a hot-melt drill bit with a diameter of 6 mm to 9 mm, and generating heat through friction, so that the tube wall around the tube hole 3 softens and extends radially into the tube as the hot-melt drill bit deepens , after cooling, a bag 5 protruding into the tube is formed;

[0020] (3) Use M8 or M10 taps to tap bag position 5;

[0021] (4) Put the meson 2 on the universal joint 4, place its end on the tube hole 3, and screw the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com