Surface treatment method for glass flake in preparation of glass flake coating

A glass flake coating and glass flake technology, applied in the coating field, can solve problems such as low production efficiency, increased water absorption, expansion, etc., and achieve the effects of reducing surface treatment time, improving treatment efficiency, and extending the diffusion path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

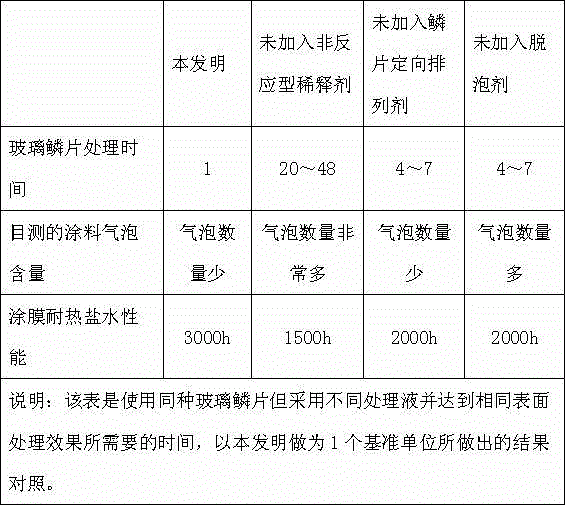

[0038] The present invention is a surface treatment method for glass flakes when preparing glass flake coatings. The surface treatment method is mainly aimed at the treatment of glass flakes before preparing glass flake coatings. Compared with the background technology, the surface treatment method of the present invention has a shorter time. , High efficiency, reduce the bubble content in the glass flake coating and form a coating film parallel to the base metal, prolong the diffusion path of the infiltrating medium, and improve the shielding performance of the coating film.

[0039] The present invention can be explained in more detail through the following examples. The present invention is not limited to the following examples. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0040] The preparation of glass flake paint involves epoxy resin, talcum powder, thixotropic agent, titanium dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com