Biodegradable packaging film material

A biodegradable and packaging film technology, applied in the direction of biological packaging, sustainable packaging industry, climate sustainability, etc., can solve the problems of non-transparent film, high surface energy, surface precipitation, etc., to improve service life and safety performance, Improves the tensile strength and impact strength, and improves the effect of phase separation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this example, the graft-coated SiO is prepared according to the following steps 2 , as the compatibility modifier used in subsequent examples:

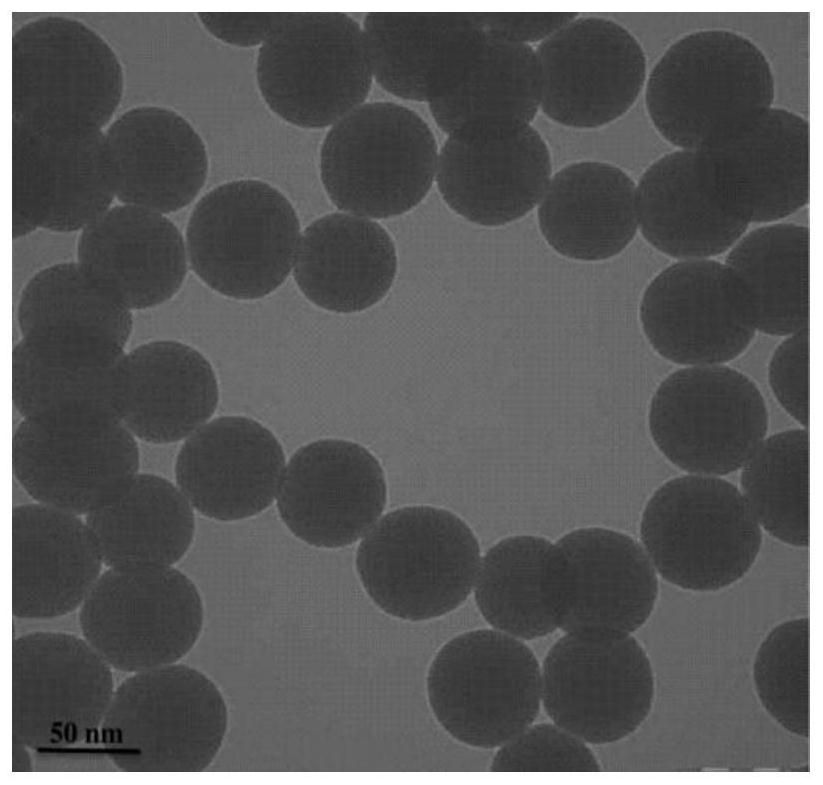

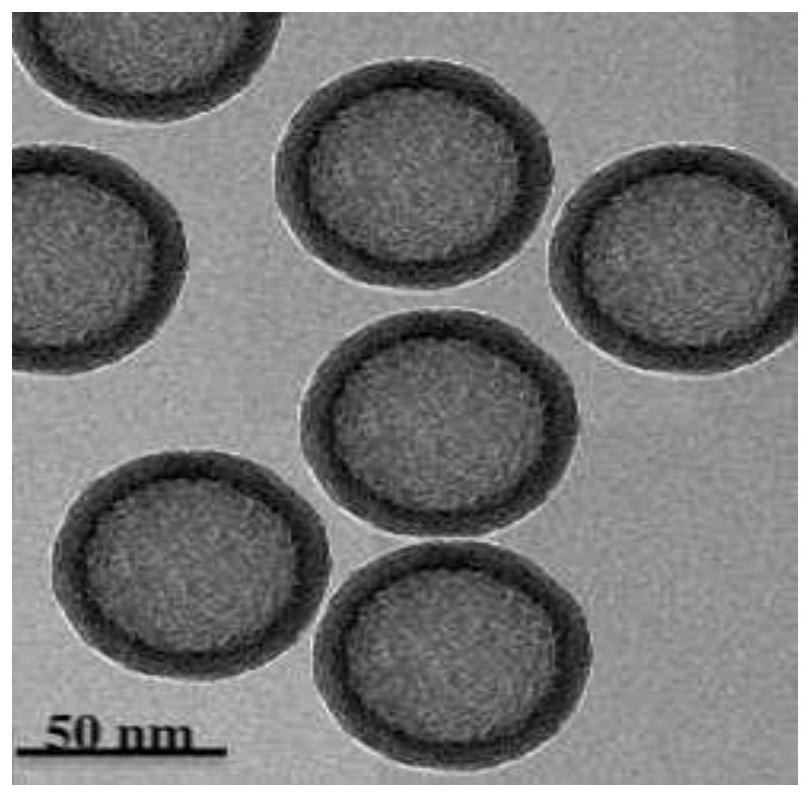

[0029] First, 10kg of SiO with a particle size of 50nm 2 (The TEM image of the figure 1 shown) poured into the reactor, then added 100kg water, 0.05kg SDS, 0.03kg PVA, stirred at 90 ° C for 1h to dissolve SDS and PVA; then added 3kg butyl acrylate, 2.5kg methacrylic acid to the reactor Glycidyl ester and 0.02kg BPO were added to the reaction kettle, mixed and stirred, and the reaction was stirred at 80 °C for 8 hours. The obtained product was filtered and dried to obtain graft-coated SiO 2 , and its TEM image is as figure 2 shown.

Embodiment 2

[0031] The composition of each raw material of the biodegradable packaging film material in this embodiment is: 6 parts of polylactic acid resin (FY804), 74 parts of polyadipate / butylene terephthalate resin (TH801T), calcium carbonate powder 20 parts, 0.1 part antioxidant 1010, 0.2 part antioxidant 168, lubricant oleic acid amide 1.5 part, lubricant calcium stearate 3 parts, UV absorber 2-hydroxy-4-n-octyloxydibenzyl 3 parts of ketone, 3 parts of graft-coated SiO 2 .

Embodiment 3

[0033] The composition of each raw material of the biodegradable packaging film material in this embodiment is: 6 parts of polylactic acid resin (FY804), 74 parts of polyadipate / butylene terephthalate resin (TH801T), calcium carbonate powder 20 parts, 0.1 part antioxidant 1010, 0.2 part antioxidant 168, lubricant oleic acid amide 1.5 part, lubricant calcium stearate 3 parts, UV absorber 2-hydroxy-4-n-octyloxydibenzyl 3 parts of ketone, 5 parts of graft-coated SiO 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com