A method of using silica gel to strengthen zinc slag to remove arsenic in polluted acid

A technology of strengthening zinc and silica gel, which is applied in the field of heavy metal pollution control, can solve the problems of not using zinc slag to remove arsenic, achieve good stability and chemical inertness, low cost, and effectively fix arsenic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The composition of the zinc slag used in this example is shown in Table 1. The dirty acid comes from the dirty acid containing a large amount of impurities such as arsenic produced after the sulfuric acid workshop of the zinc smelter in Southwest China washes the smelting flue gas. The main components are shown in Table 2;

[0019] Table 1 Composition of Zinc Slag

[0020] Zinc dross Fe Ca S Si Al Mg Zn mn F O Proportion(%) 30.0 14.4 2.2 3.0 2.3 1.8 1.7 1.1 0.7 Balence

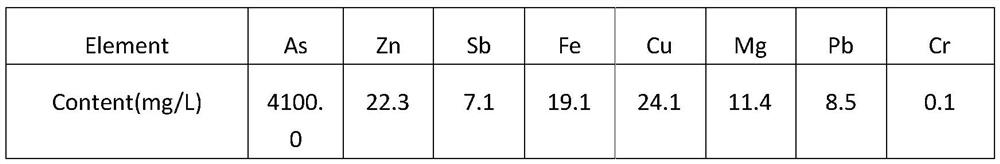

[0021] Table 2 Sewage Acid Components

[0022]

[0023] The method described in this embodiment utilizes silica gel to strengthen zinc slag to remove arsenic in polluted acid, and the specific steps are as follows:

[0024] (1) Finely grind the zinc slag through a 200-mesh sieve to obtain zinc slag powder.

[0025] (2) Mixing the zinc slag powder and the silica gel solution in step (1) to obtain the arsenic removal agent; wherein the mass ratio of the zi...

Embodiment 2

[0035] The composition of the zinc slag used in this example is shown in Table 5. The dirty acid comes from the sulfuric acid workshop of the zinc smelter in Southwest China, which contains a large amount of impurities such as arsenic. The main components are shown in Table 6.

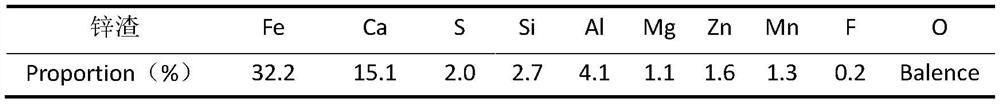

[0036] Table 5 Composition of Zinc Slag

[0037]

[0038] Table 6 Pollution Acid Components

[0039]

[0040] The method described in this embodiment utilizes silica gel to strengthen zinc slag to remove arsenic in polluted acid, and the specific steps are as follows:

[0041] (1) Finely grind the zinc slag through a 200-mesh sieve to obtain zinc slag powder.

[0042] (2) Mixing the zinc slag powder and the silica gel solution in step (1) to obtain the arsenic removal agent; wherein the mass ratio of the zinc slag powder to the silica gel solution is 5:1, and the silica gel solution is a commercially available product.

[0043] (3) Step (2) arsenic removal agent and H 2 o 2 Add it into the ar...

Embodiment 3

[0052] The composition of the zinc slag used in this example is shown in Table 9. The dirty acid comes from the sulfuric acid workshop of the zinc smelter in Southwest China, which contains a large amount of impurities such as arsenic. The main components are shown in Table 10.

[0053] Table 9 Composition of Zinc Slag

[0054] Zinc dross Fe Ca S Si Al Mg Zn mn F O Proportion(%) 34.2 16.4 2.2 3.6 4.1 1.9 1.6 2.1 0.2 Balence

[0055] Table 10 Sewage Acid Components

[0056]

[0057]

[0058] The method described in this embodiment utilizes silica gel to strengthen zinc slag to remove arsenic in polluted acid, and the specific steps are as follows:

[0059](1) Finely grind the zinc slag through a 200-mesh sieve to obtain zinc slag powder.

[0060] (2) Mixing the zinc slag powder and the silica gel solution in step (1) to obtain the arsenic removal agent; wherein the mass ratio of the zinc slag powder to the silica gel solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com