Battery structure capable of injecting liquid from bottom and battery liquid injection method

A battery and liquid injection technology, applied in structural parts, battery pack parts, circuits, etc., can solve problems such as electrolyte waste, corrosion of liquid injection devices, and inability to ensure full infiltration of internal cells, so as to improve fluency and ensure wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

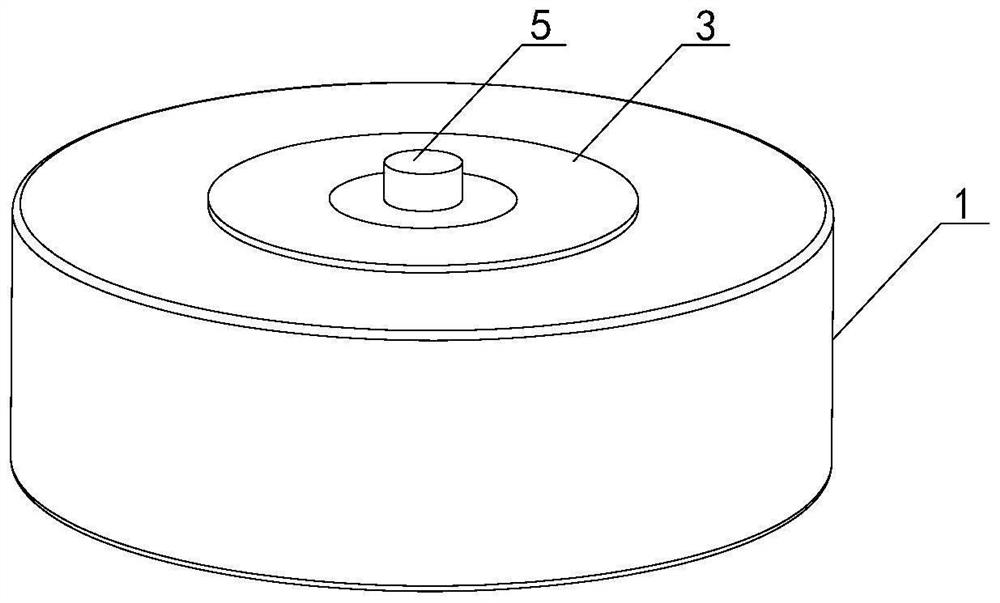

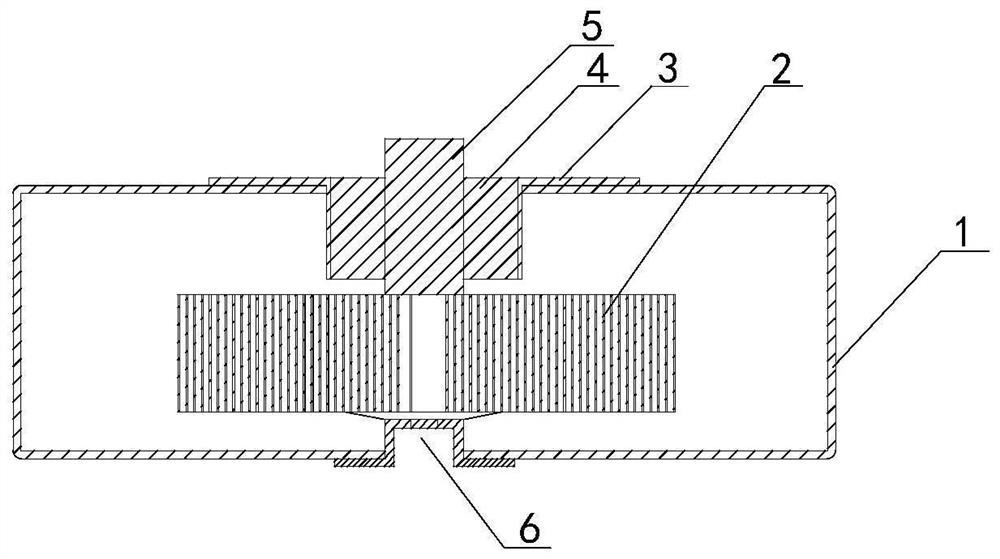

[0052] Such as figure 1 , figure 2 , image 3 , Image 6 As shown, the battery structure with liquid injection from the bottom implemented by the technical solution of the present invention includes a battery case 1 with a cylindrical structure, and its interior is set as a hollow structure, so as to be used for assembling the battery cell 2 and containing the injected electrolyte , a molybdenum rod pole 5 is arranged at the center of the battery cell 2. Since an opening is provided on the top of the battery case 1, the molybdenum rod pole 5 can pass through the battery case 1 from bottom to top and extend to the battery case 1. The outside, wherein the opening is also used to install the ring-shaped steel ring 3 that can seal and fix the assembled battery cell 2 to a certain extent. The gap between the pole 5 and the steel ring 3 is filled with an annular glass layer 4. The structure implemented above forms the basic part of the battery structure. It is based on this basi...

Embodiment 2

[0056] Such as Figure 4-5 As shown, the battery structure of injecting liquid from the bottom implemented in Embodiment 2 of the present invention is the supplement and improvement of the technical means implemented in Embodiment 1. On the premise of improving the fluency of the battery liquid injection operation, technicians Corresponding technical means can also be further implemented to form corresponding technical solutions, specifically including:

[0057] A ring-shaped support assembly 7 is horizontally added to the bottom surface of the inner chamber of the battery case 1 around the periphery of the implemented liquid injection hole position 6. Of course, for the specific material of the support assembly 7, an assembly that has no effect on the performance of the battery cell 2 can be selected, and further , two layers of diversion supports are set above the implemented support assembly 7, and from the inside to the outside are diversion supports one 8 and diversion su...

Embodiment 3

[0062] Such as Figure 1-4 As shown, Embodiment 3 of the present invention implements a battery liquid injection method, which is a supplement and improvement to the technical means implemented in Embodiment 1 or Embodiment 2. On the premise that it is beneficial to improve the fluency of battery liquid injection operation, Technicians can further implement corresponding technical means according to the battery structure to form corresponding method steps, specifically including:

[0063] (1) Select the battery to be injected with electrolyte, open a liquid injection hole 6 at the center of the bottom surface of the shell, and align the middle space area 10 of the battery 2 when assembling the battery 2 into the battery. The liquid injection hole 6, so that the liquid injection hole 6 is kept in communication with the middle space area 10;

[0064] (2) Inject the electrolyte solution from the set liquid injection hole 6 from the bottom up to the inside of the battery, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com