Method for improving gas circulation uniformity of vertical tubular furnace

A tube furnace, uniformity technology, applied in the direction of furnace, crucible furnace, furnace type, etc., can solve the problems of difficult gas passage, gas blockage, unstable crucible placement, etc., and achieve the effect of improving accuracy and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Method for improving the uniformity of vertical tubular furnace gas.

[0025] (1) First, the central position of the solid cylindrical plug in the diameter of 200 mm is opened to a hole in diameter of 10 mm, so that it runs through the entire plug;

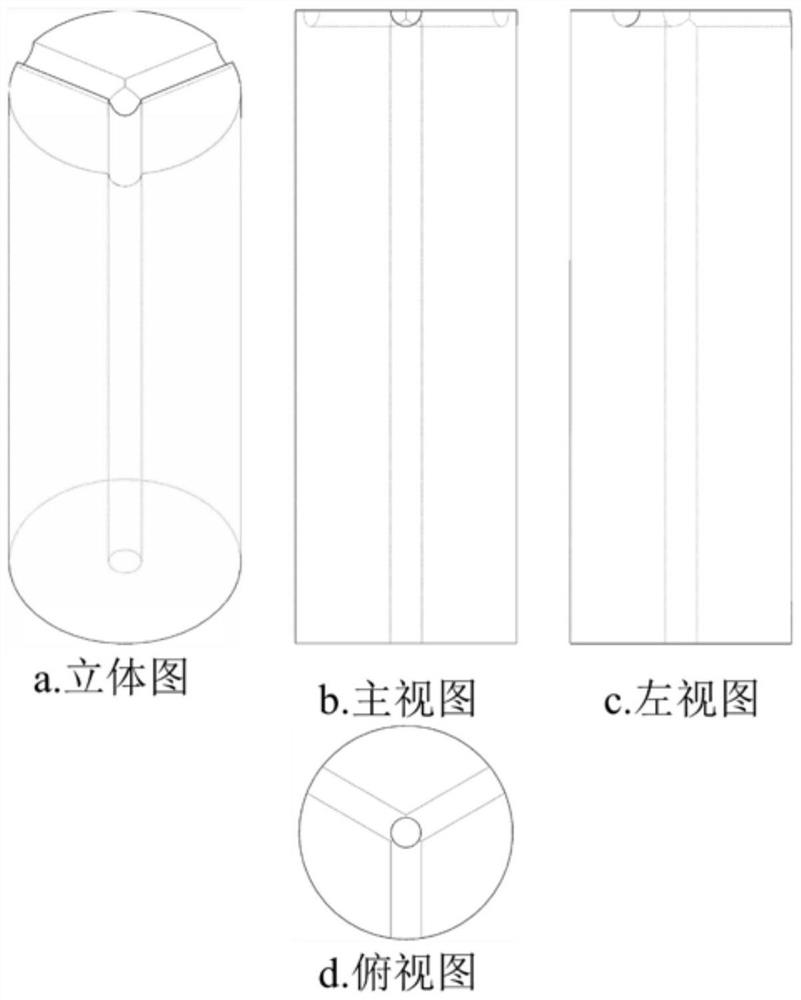

[0026] (2) Place the plug of the penetrating holes in step (1), at the top, from the circumferential direction, 3 towards a uniform semicircular passage of 3 mm distribution in the radial center in the radial direction. Schematic figure 1 Indicated. When the gas flows upward from the plug, reaching the top of the crucible is dispersed to three passages to be diffused above, and the gas flow uniformity conditions are improved.

Embodiment 2

[0027] Example 2: A method of improving the uniformity of vertical tubular furnace gas.

[0028] (1) First, the central position of the solid cylindrical plug in the diameter of 200 mm is opened to a hole in diameter of 10 mm, so that it runs through the entire plug;

[0029] (2) Place the plug of the penetrating holes in step (1), at the top, from the circumference, toward the center of 4 having a uniform diameter of 10 mm to the center in the radial direction. Schematic figure 2 Indicated. When the gas flows upward from the plug, reaching the top of the crucible is dispersed to four passages to diffuse overward, and the gas flow uniformity conditions are improved.

Embodiment 3

[0030] Example 3: A method of improving the uniformity of vertical tubular furnace gas.

[0031] (1) First, the central position of the solid cylindrical plug in the diameter of 200 mm is opened to a hole in diameter of 10 mm, so that it runs through the entire plug;

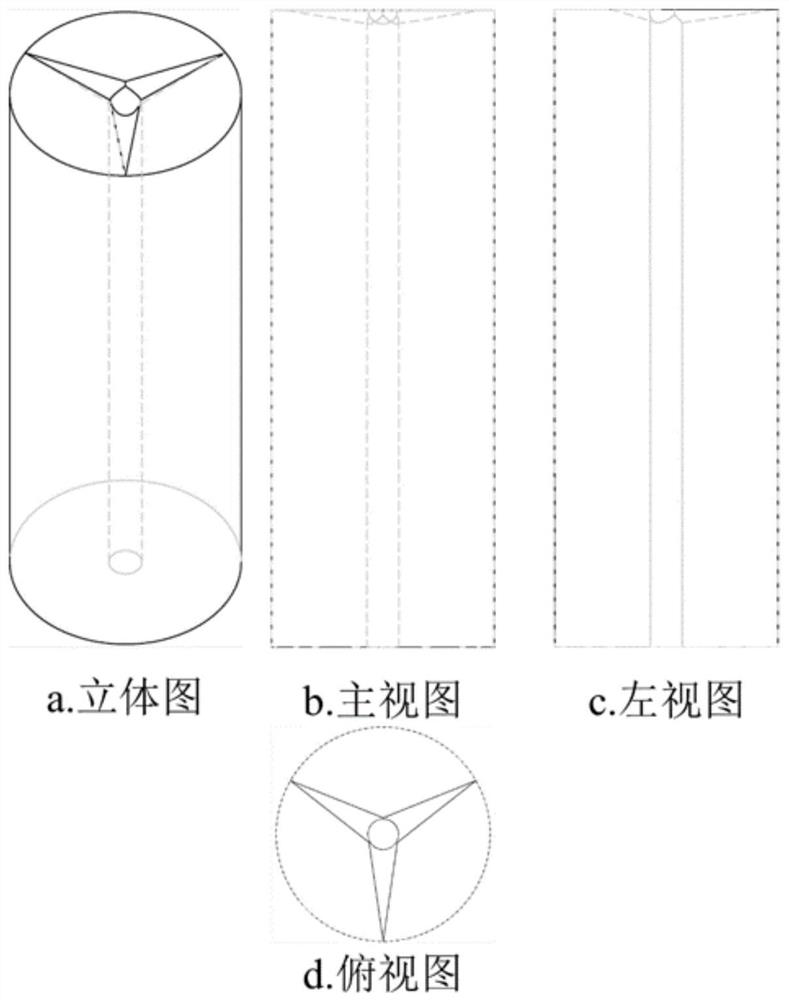

[0032] (2) Place the plug of the penetrating hole in the step (1), and 35 mm of 35 mm, a height of 35 mm, a height of 35 mm, and a uniform distribution. Schematic image 3 Indicated. When the gas flows upward from the plug, reaching the top of the crucible is dispersed to three passages to be diffused above, and the gas flow uniformity conditions are improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com