Joint construction method of inclined surface of ring road in test yard

A construction method and test field technology, applied in the directions of roads, roads, pavement details, etc., can solve the problems of slow temperature drop, affecting flatness and stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

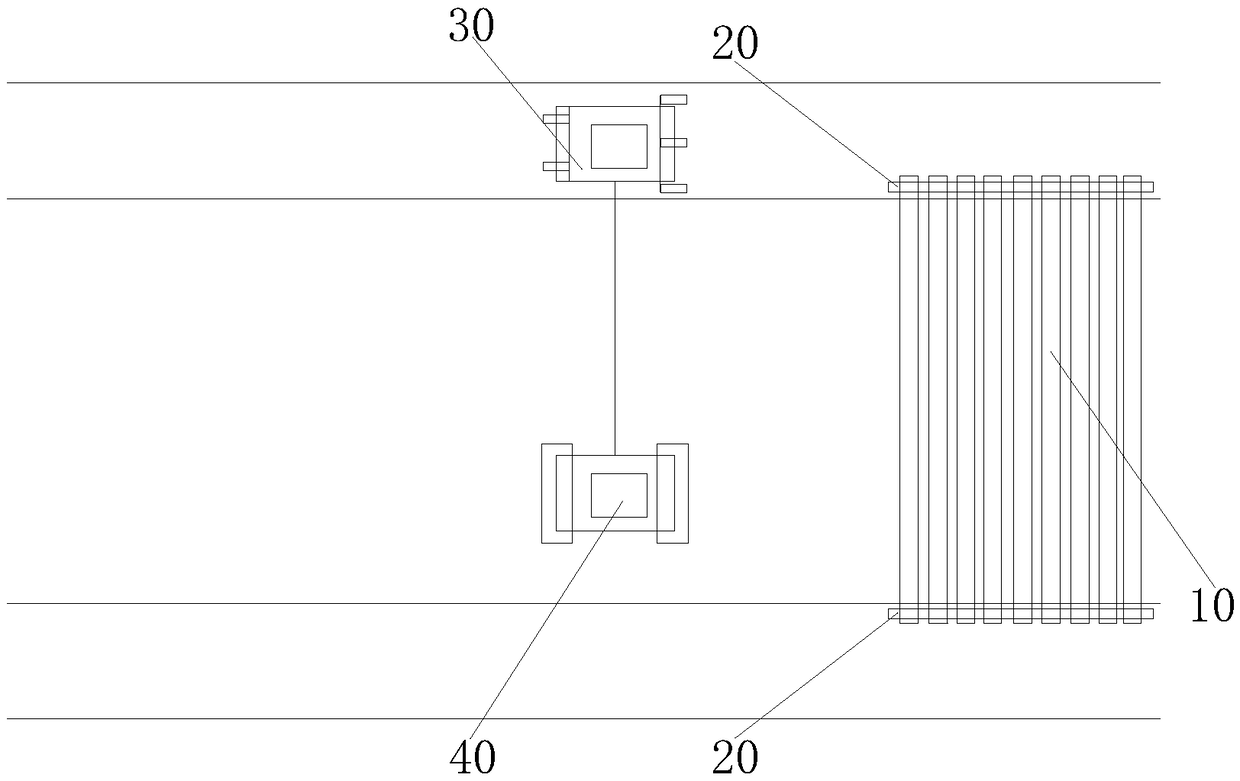

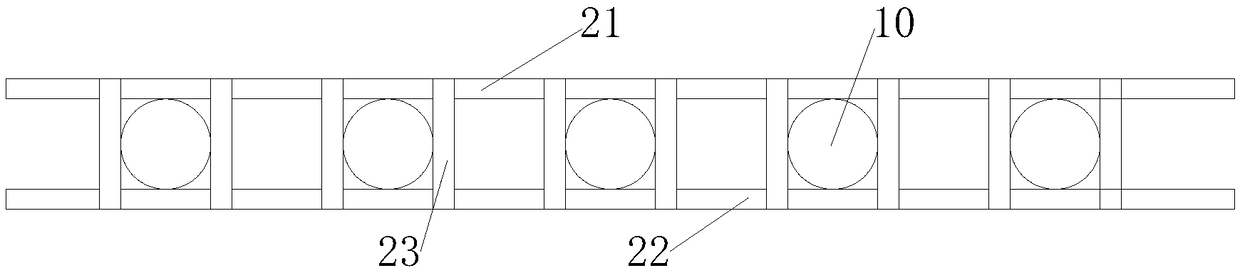

[0014] combined with Figure 1~3 The present invention is further described:

[0015] A joint construction method for the inclined surface of the ring road of a proving ground, comprising the following steps:

[0016] A. According to the design requirements of the slope of the ring road, lay the slope base in advance, and then lay the graded crushed stone mixture on the slope base;

[0017] B. Begin to pave the asphalt layer in sections along the length direction of the slope of the ring road, lay stainless steel pipe 10 in front of the cut-off face of the asphalt layer, and lay the stainless steel pipe 10 along the slope of the slope of the ring road from top to bottom;

[0018] C, start from the truncated surface of the asphalt layer, adopt a paver to continue laying a new asphalt layer on the top of the stainless steel pipe 10;

[0019] D, then arrange the road roller to roll the new asphalt layer along the length direction of the slope of the ring road, use the water inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com