Preparation method of diaphragm modification material for lithium-sulfur battery

A technology for lithium-sulfur batteries and diaphragm materials, applied in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problems of slowing lithium ion conduction, decreasing reaction kinetics, and difficult to adsorb polysulfides, etc. Improved cycle stability, simple implementation process, and the effect of suppressing the shuttle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

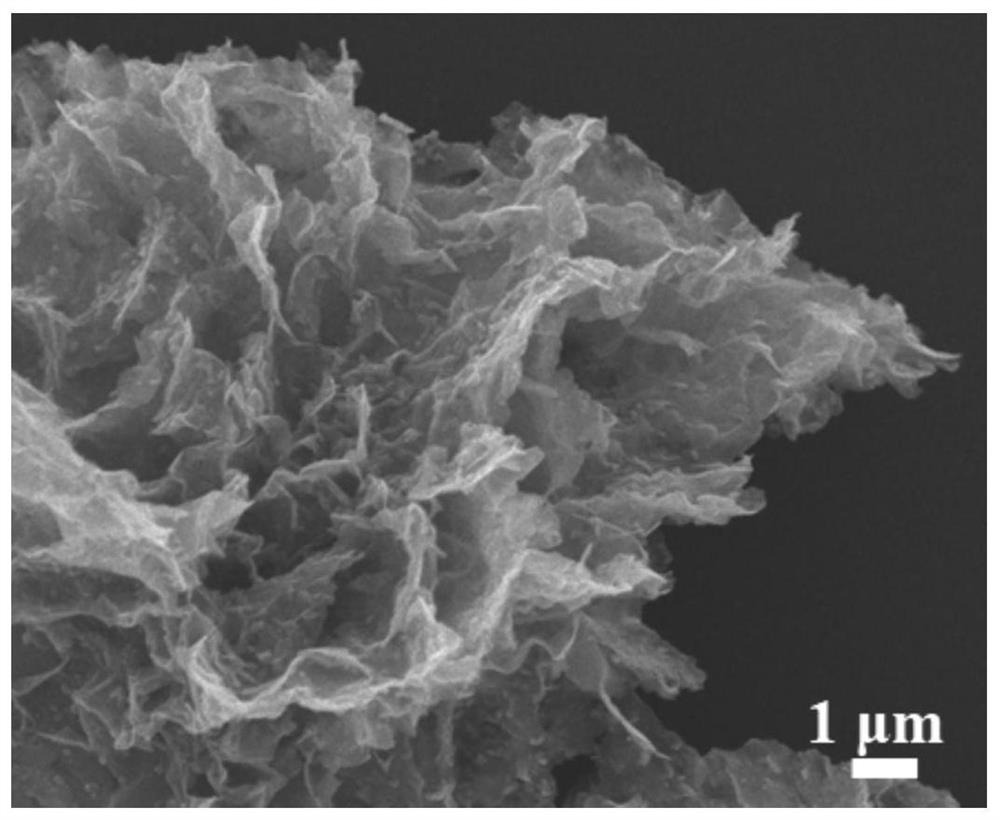

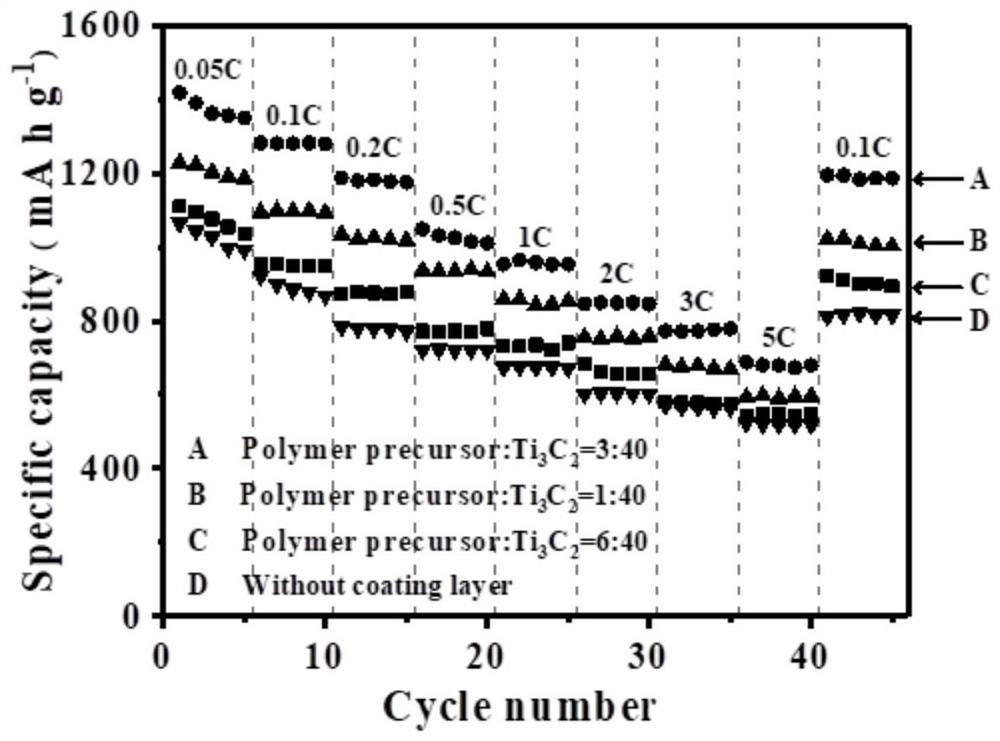

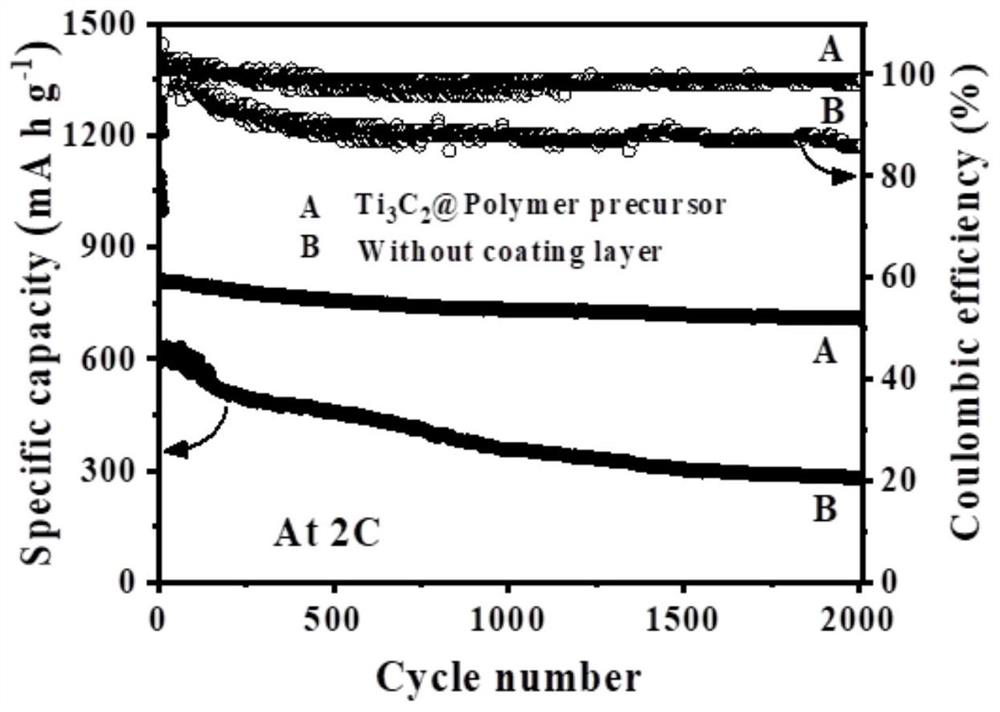

[0038] Take Ti 3 C 2 Colloidal dispersion (5mg / mL, 25mL), add 85 ml of 1,4-dioxane, add 5.4 mg of triaminoguanidine hydrochloride to the above dispersion, ultrasonically disperse for 30 minutes, add 8.1 mg of 1,3,5-triformylphloroglucinol, so that the total mass of triaminoguanidine hydrochloride and 1,3,5-triformylphloroglucinol and Ti 3 C 2 The mass ratio of the template is 3:40. The resulting mixture was processed 3 times continuously through the freeze-vacuum-thaw process, and then the sealed Pyrex bottle was placed at 120 °C for 3 days, and the resulting solid powder was washed sequentially with N,N-dimethylacetamide, water and acetone , and the ionomer-coated two-dimensional material was obtained after vacuum drying. Subsequently, 12.56 mg of the above-mentioned material and polyvinylidene fluoride were uniformly mixed at a mass ratio of 9:1, and suction filtered onto a Celgard 2400 polypropylene diaphragm substrate to obtain the lithium-sulfur battery diaphragm of t...

Embodiment 2

[0044] Take Nb 2 C colloidal dispersion (8 mg / mL, 25 mL), add 85 ml of 1,4-dioxane, add 8.9 mg of triaminoguanidine hydrochloride to the above dispersion, ultrasonically disperse for 40 minutes, add 13.4 mg 1,3,5-triformylphloroglucinol, so that the total mass of triaminoguanidinium hydrochloride and 1,3,5-triformylphloroglucinol and Ti 3 C 2 The mass ratio of the template is 6:40. The resulting mixture was processed 3 times continuously through the process of freezing-vacuumizing-thawing, and then the sealed Pyrex bottle was placed at 120 °C for 3 days, and the resulting solid powder was washed sequentially with N,N-dimethylacetamide, water and acetone , and the ionomer-coated two-dimensional material was obtained after vacuum drying. Subsequently, 10.50 mg of the above-mentioned material and polyvinylidene fluoride were uniformly mixed in a mass ratio of 9:1, and suction filtered onto a Celgard 2400 polypropylene separator substrate to obtain the lithium-sulfur battery se...

Embodiment 3

[0046] Take Ti 3 C 2 Colloidal dispersion (6mg / mL, 25mL), add 85ml of N-methylpyrrolidone, add 1.8mg of triaminoguanidine hydrochloride to the above dispersion, ultrasonically disperse for 30 minutes, add 2.7mg of 1,3, 5-triformylphloroglucinol, so that the total mass of triaminoguanidine hydrochloride and 1,3,5-triformylphloroglucinol and Ti 3 C 2 The mass ratio of the template is 1:40. The resulting mixture was processed 3 times continuously through the process of freezing-vacuumizing-thawing, and then the sealed Pyrex bottle was placed at 120 °C for 3 days, and the resulting solid powder was washed sequentially with N,N-dimethylacetamide, water and acetone , and the ionomer-coated two-dimensional material was obtained after vacuum drying. Subsequently, 12.00 mg of the above-mentioned material and polyvinylidene fluoride were uniformly mixed at a mass ratio of 9:1, and suction filtered onto a Celgard 2400 polypropylene diaphragm substrate to obtain the lithium-sulfur bat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com