A method for rebuilding waterproof layer with minimally invasive technology

A waterproof layer and technology, applied in building construction, building maintenance, infrastructure engineering, etc., can solve the problems of complex operation, large amount of materials, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A method for reconstructing a waterproof layer with a minimally invasive technique, the scheme is as follows:

[0031] Step 1: Block the cracks, clean up the cracks on the building surface that needs to be repaired, and then use the quick-curing mortar to seal up the surprise of the cracks;

[0032] Step 2: Drill holes, drill grouting holes on the building surface to be repaired, and the number of holes is 4 / m 2 , and bury the grouting needle in the grouting hole;

[0033] Step 3, inject filler, inject back filler from the grouting hole, and the back filler is prepared according to the following method:

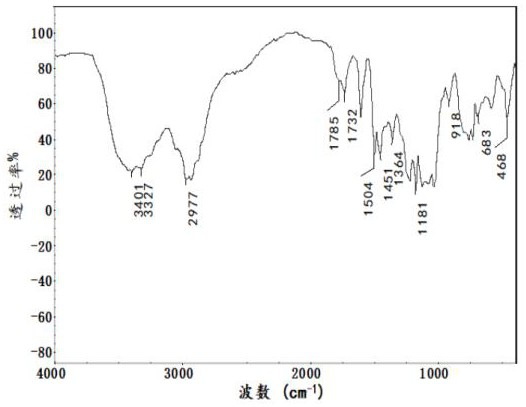

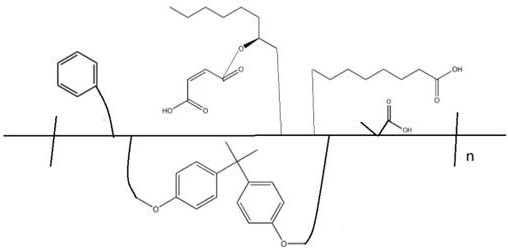

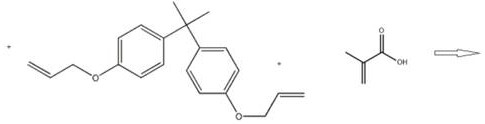

[0034] With 20kg methacrylic acid, 10kg styrene, 15kg ricinoleate maleate and 0.1kg diallyl bisphenol A, add 0.8kg initiator after stirring and mixing, slowly add 30kg ethylene glycol butyl after stirring and mixing Add 15.6kg of expanded perlite, 10.2kg of mica powder, 3.2kg of expanded rubber powder and 1.5kg of carbon black powder into the reaction kettle after co...

Embodiment 2

[0043] A method for reconstructing a waterproof layer with a minimally invasive technique, the scheme is as follows:

[0044] Step 1: Block the cracks, clean up the cracks on the building surface that needs to be repaired, and then use the quick-curing mortar to seal up the surprise of the cracks;

[0045] Step 2: Drill holes, drill grouting holes on the building surface to be repaired, and the number of holes is 6 / m 2 , and bury the grouting needle in the grouting hole;

[0046] Step 3, inject filler, inject back filler from the grouting hole, and the back filler is prepared according to the following method:

[0047] After stirring and mixing 25kg methacrylic acid, 13kg styrene, 18kg ricinoleate maleate and 0.3kg diallyl bisphenol A, add 1kg initiator, slowly add 40kg butyl glycol ether after stirring and mixing control the temperature to 100℃ for 4h, after the reaction is completed, add 22.4kg expanded perlite, 13.6kg mica powder, 4.8kg expanded rubber powder and 2.5kg ca...

Embodiment 3

[0056] A method for reconstructing a waterproof layer with a minimally invasive technique, the scheme is as follows:

[0057] Step 1: Block the cracks, clean up the cracks on the building surface that needs to be repaired, and then use the quick-curing mortar to seal up the surprise of the cracks;

[0058] Step 2. Drill holes, drill grouting holes on the building surface to be repaired, and the number of holes is 8 / m 2 , and bury the grouting needle in the grouting hole;

[0059] Step 3, inject filler, inject back filler from the grouting hole, and the back filler is prepared according to the following method:

[0060] With 30kg methacrylic acid, 15kg styrene, 22kg ricinoleate maleate and 0.5kg diallyl bisphenol A, add 1.2kg initiator after stirring and mixing, slowly add 50kg ethylene glycol butyl after stirring and mixing Add 32.2kg expanded perlite, 16.6kg mica powder, 6.8kg expanded rubber powder and 4.5kg carbon black powder to the reaction kettle after the reaction is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com