Method and system for coordinated optimization of low-energy grain boundary density and grain size

A technology of grain size, coordinated optimization, applied in the field of metal plastic forming, can solve the problems of low-energy grain boundary density and grain size, and achieve the effect of high low-energy grain boundary density and improved valve performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

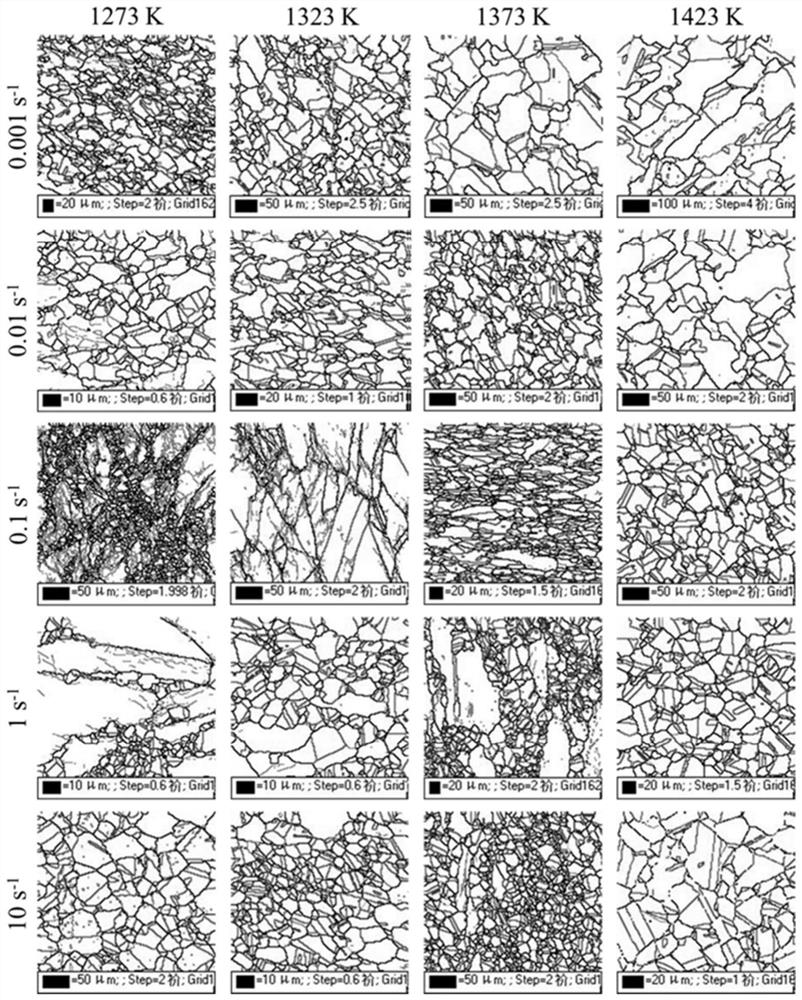

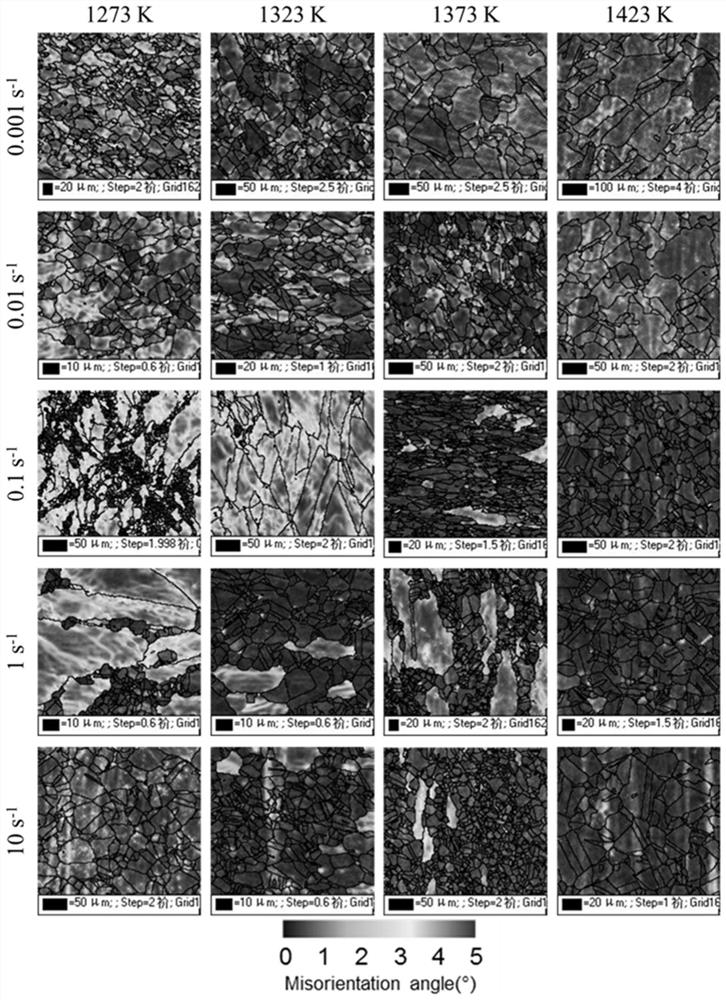

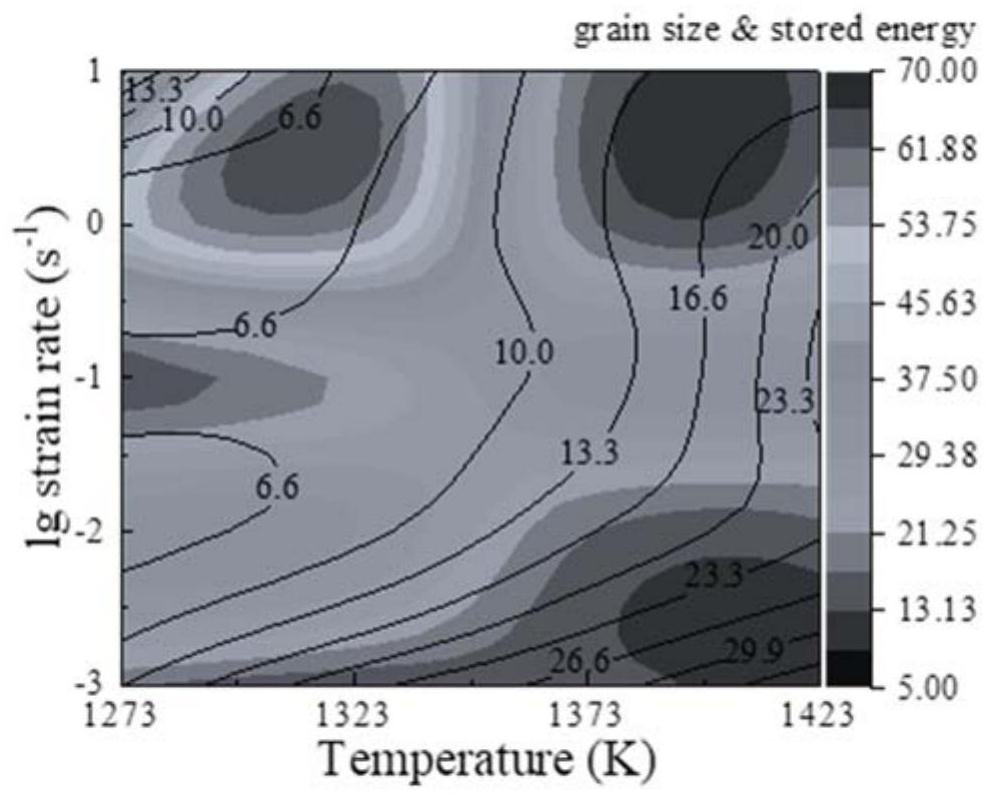

[0042] 1) Establish the response relationship between energy storage and grain size

[0043] During the deformation process, the stored energy of the deformed material can be estimated by the dislocation density.

[0044]

[0045] where G is the shear modulus, b is the absolute value of the Burger vector, ρ is the dislocation density, K is the arithmetic mean of 1 and (1-ν), and ν is Poisson's ratio.

[0046] The dislocation density ρ is related to the steady-state flow stress σ, as shown in formula (2), where c 1 is a constant.

[0047]

[0048] During the steady-state thermal deformation of the material, the average grain size and the steady-state flow stress have a power-law relationship, as shown in formula (3).

[0049]

[0050] Among them, n is the correlation index with the grain size, ranging from 0.4 to 0.8; c 2 is a constant.

[0051] Therefore, combining formula (1), formula (2) and formula (3), the formula of energy storage can be expressed as formula ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com