Method for screening high-yield cellulase filamentous fungi through self-adaptive mutagenesis

A technology of mutagenesis screening and cellulose, applied in the direction of using spores, methods based on microorganisms, fungi, etc., can solve the problems of reducing mutation efficiency, affecting mutagenesis effects, and difficulties in high-yield cellulase strains

Pending Publication Date: 2021-06-01

XIAMEN UNIV

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

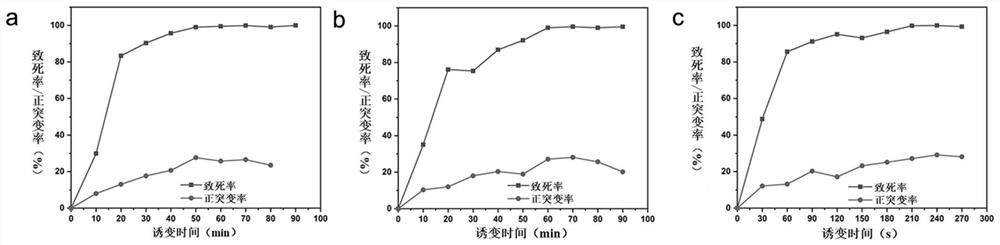

However, different mutagenesis media have different advantages and disadvantages. The use of chemical mutagens can greatly increase the enzyme activity of the target strain, but the resulting mutants are prone to reverse mutations during the passage process. The same situation often exists in ultraviolet mutagenesis. In the process (photoreactivation repair, Photoreactivation Repair), while the genetic stability of mutants obtained from mutagenic sources such as ARTP and heavy ions is good, but the increase in enzyme activity is not high, how to balance the forward mutation rate of mutants and genetic Stability is a major focus in the course of future research

In addition, single rounds of mutagenesis and multiple rounds of mutagenesis will also affect the final mutagenesis effect, and repeated treatments of a single mutagenesis technique often reduce the mutation efficiency

[0004] In addition, it is also very difficult to effectively mutate Trichoderma afroharzianum to obtain a strain with high cellulase production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0046] The present invention will be further described below through specific examples, so as to better understand the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

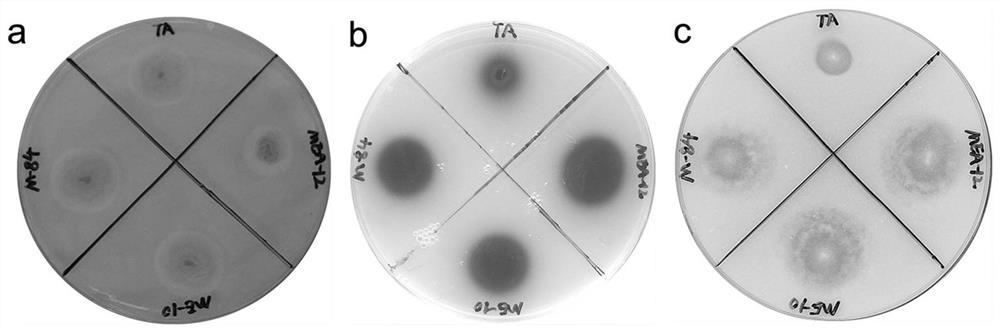

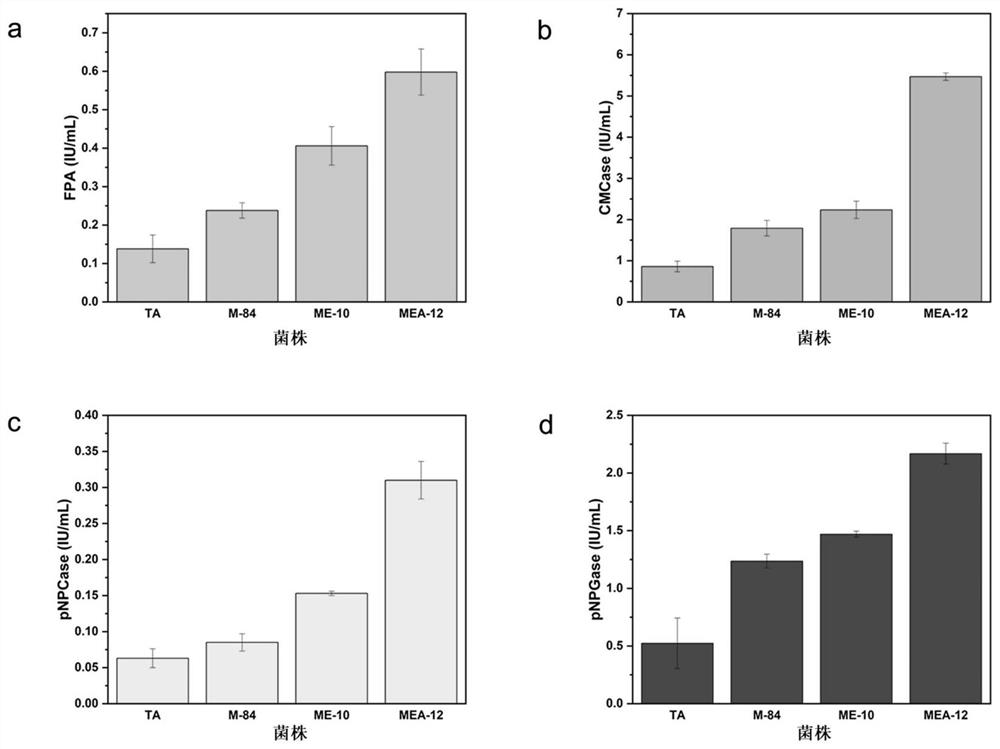

The invention discloses a method for screening high-yield cellulase filamentous fungi through self-adaptive mutagenesis and an obtained mutant strain, and particularly relates to mutation of Trichoderma harzianum. The method comprises the following specific steps: preparing a wild type African trichoderma harzianum spore suspension; carrying out three rounds of mutagenesis on the wild type African trichoderma harzianum; screening mutant strains; and determining the enzyme activity stability of the excellent mutant strain. The strain is mutagenized through three rounds of self-adaptive mutagenesis, so that the mutagenesis purposiveness is strong, and the practicability is high. According to the method disclosed by the invention, a mutant strain MEA-12 of which the cellulase activity is remarkably improved (FPA is improved by 3.17 times, CMCase is improved by 4.77 times, pNPCase is improved by 3.86 times and pNPGase is improved by 2.97 times) and the genetic character is stable is finally obtained through mutagenesis screening, and the mutant strain MEA-12 has important value in industrial cellulase preparation production.

Description

technical field [0001] The invention belongs to the technical field of industrial microorganisms, and in particular relates to a method for self-adaptive mutagenesis screening of filamentous fungi with high cellulase production and the obtained mutant strains. Background technique [0002] Cellulose is widely distributed in nature and is one of the most promising raw materials for biotransformation. As an ideal substitute for traditional fossil energy, cellulosic biomass-derived ethanol fuel has attracted the attention of various countries. Cellulose fuel ethanol can be produced by thermochemical as well as biochemical methods. Cellulase is the key to converting cellulosic biomass into fermentable sugars for fuel ethanol production. The cellulase used in this process is a complex enzyme, which contains endoglucanase (EC3.2.1.4), cellobiohydrolase (EC3.2.1.91) and β-glucosidase (EC3.2. 1.21), according to the C1-Cx hypothesis, the above three cellulase enzymes act synergis...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C12N15/01C12N13/00C12N3/00C12N1/14C12R1/885

CPCC12N15/01C12N13/00C12N3/00C12N1/14Y02E50/10

Inventor 曾宪海彭志清吴升山李闯唐兴孙勇林鹿

Owner XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com