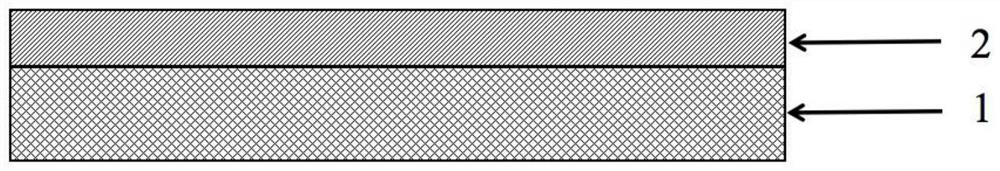

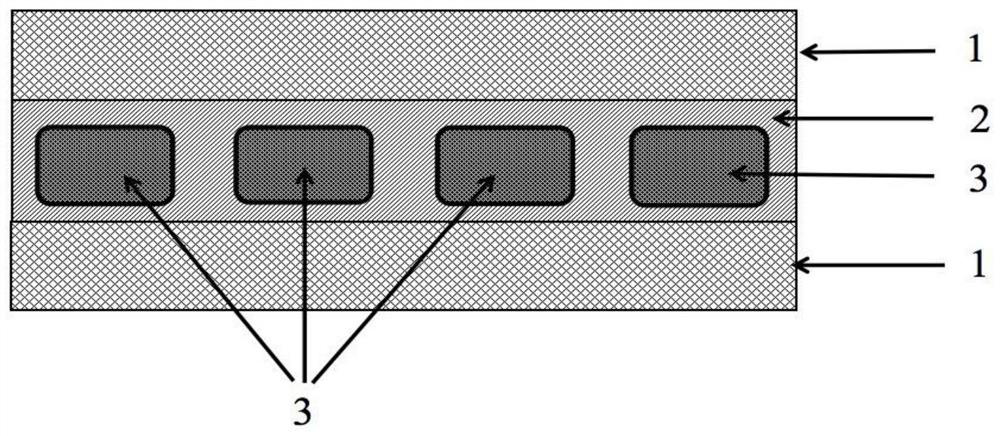

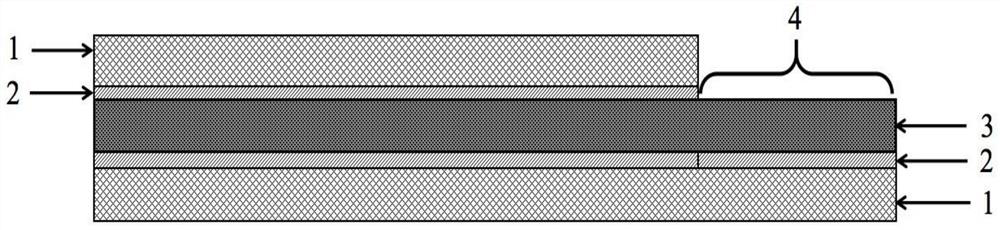

Hot-pressed insulating film and flexible flat cable comprising same

A flexible flat, insulating film technology, used in insulated cables, flat/ribbon cables, insulated conductors, etc., can solve the problems of materials that cannot meet long-term outdoor use, insufficient service life, and attenuation of bonding strength, and achieve excellent long-term The effect of weather resistance, good weather resistance and excellent adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Saturated polyester resin Vylon670 / 80 parts, saturated polyester resin Vylon200 / 20 parts, flame retardant OP935 / 50 parts, flame retardant MC6000 / 30 parts, curing agent BL3175 / 15 parts, curing accelerator DBTDL / 0.1 parts, dispersed Auxiliary KBM403 / 1 part, hydrolysis-resistant auxiliary agent V04 / 1 part, use methyl ethyl ketone solvent / 100 parts to make solution of the above resin, then add flame retardant and dispersing aid to disperse to make slurry, then add curing agent, Curing accelerators and hydrolysis-resistant additives are used to make adhesive glue.

Embodiment 2

[0055] Saturated polyester resin Vylon630 / 75 parts, saturated polyester resin Vylon200 / 25 parts, flame retardant OP935 / 50 parts, flame retardant MC6000 / 20 parts, curing agent BL3175 / 15 parts, curing accelerator DBTDL / 0.1 parts, dispersed Auxiliary KBM403 / 1 part, hydrolysis-resistant auxiliary agent V04 / 1 part, use methyl ethyl ketone solvent / 100 parts to make solution of the above resin, then add flame retardant and dispersing aid to disperse to make slurry, then add curing agent, Curing accelerators and hydrolysis-resistant additives are used to make adhesive glue.

Embodiment 3

[0057] Saturated polyester resin ES320 / 80 parts, saturated polyester resin ES120 / 20 parts, flame retardant OP935 / 50 parts, flame retardant MC6000 / 30 parts, curing agent BL3175 / 15 parts, curing accelerator DBTDL / 0.1 parts, dispersed Auxiliary KBM403 / 1 part, hydrolysis-resistant additive P200 / 1 part, use methyl ethyl ketone solvent / 100 parts to make solution of the above resin, then add flame retardant and dispersing aid to disperse to make slurry, then add curing agent, Curing accelerators and hydrolysis-resistant additives are used to make adhesive glue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com