Method for preparing black nano TiO2 through thermal reduction of Mg

A nano and white technology, applied in nanotechnology, titanium oxide/hydroxide, titanium dioxide, etc., can solve the problems of high reaction temperature, high cost, harmful to human body, etc., and achieve simple preparation process, low cost, and enhanced light absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

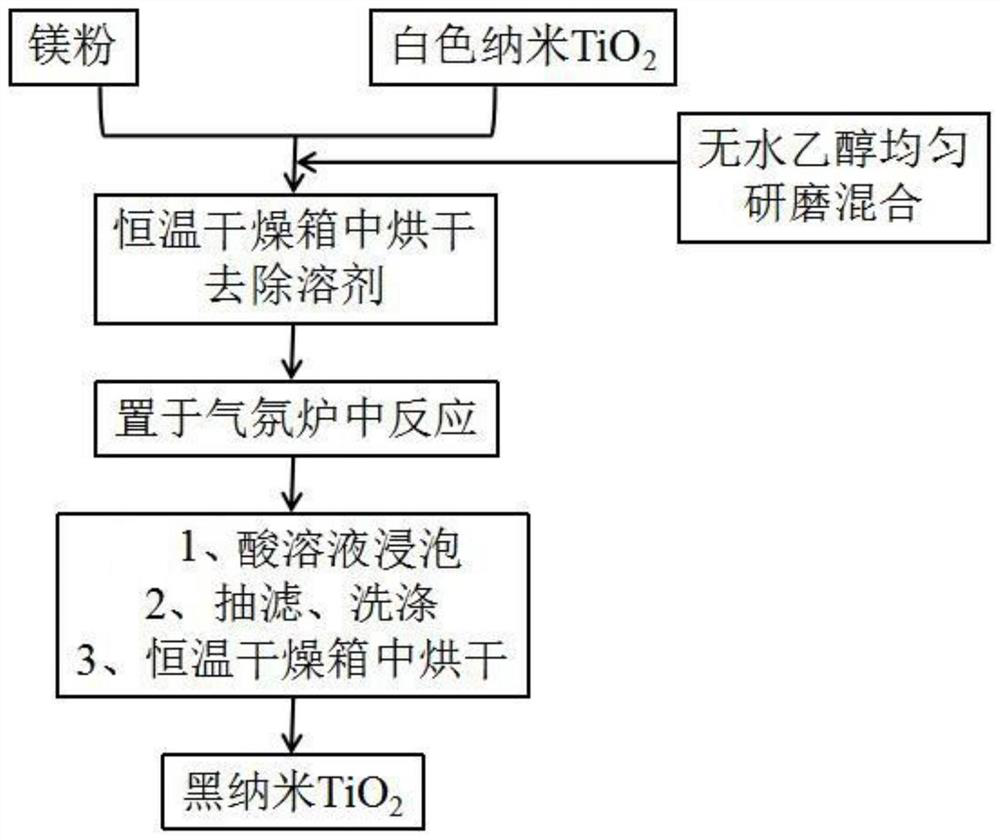

[0043] In this embodiment, a kind of Mg thermal reduction prepares black nano-TiO 2 method, including the following steps:

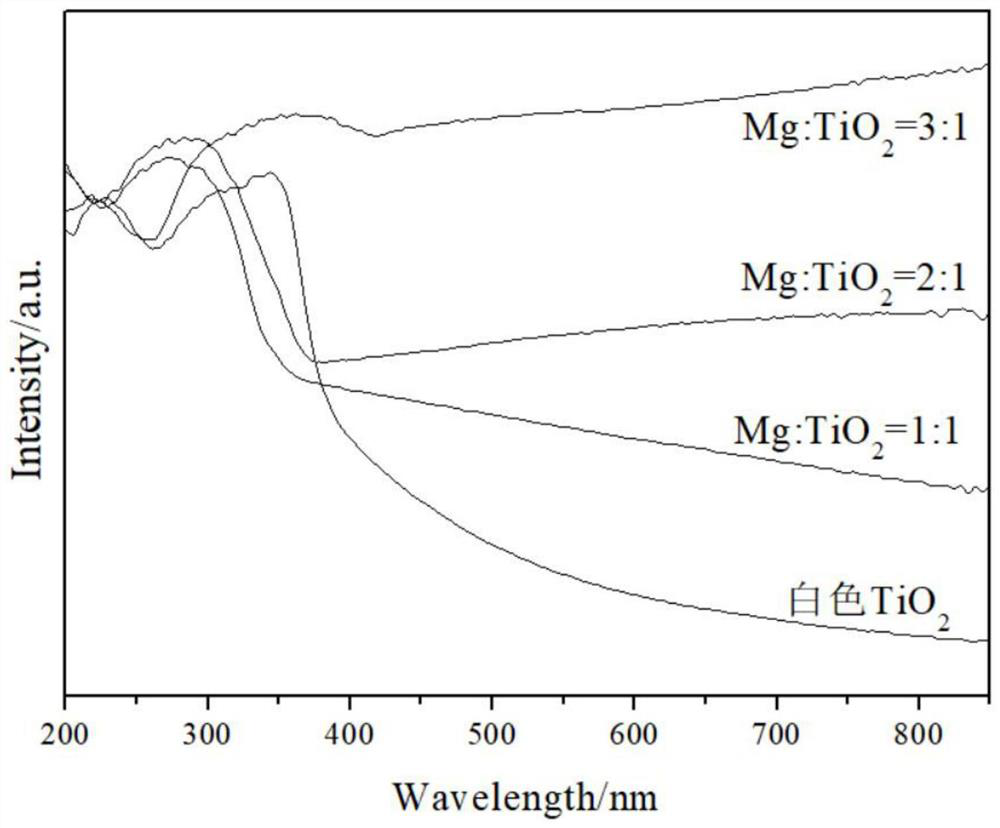

[0044] 1) At room temperature, take an agate mortar, take 0.08g magnesium powder, 0.50g commercial nano-TiO 2 Mix, then add 4.00ml of absolute ethanol to grind and mix evenly to obtain mixture A;

[0045] 2) Put the mixture A into a constant temperature drying oven, bake at 80°C for 4 hours, and remove the solvent;

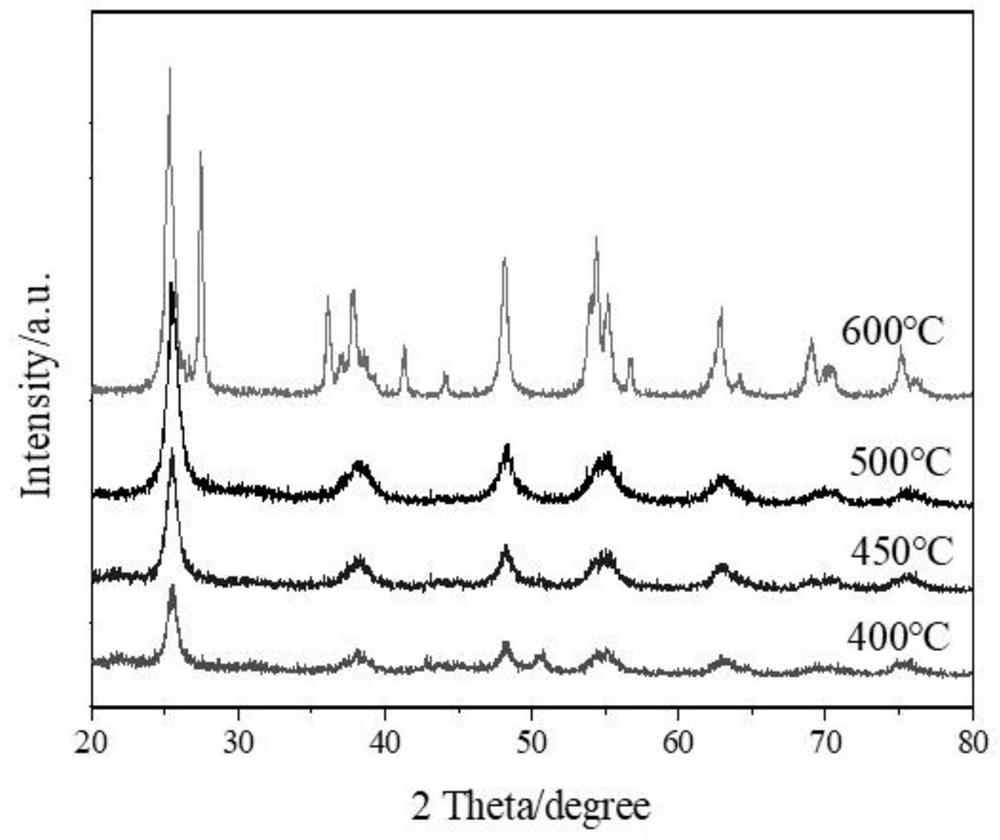

[0046] 3) Put the dried material into a crucible, place it in an argon atmosphere furnace, and calcinate at 500°C for 4 hours at a heating rate and cooling rate of 5°C / min to obtain sample B;

[0047] 4) Take sample B out, add a hydrochloric acid solution with a mass concentration of 8%, soak for 6 hours, repeat 3 times, filter and wash with deionized water 4 times;

[0048] 5) Put the washed sample B into a constant temperature drying oven, and bake it at 80°C for 4 hours to obtain black nano-TiO 2 product.

[0049] The prepared black ...

Embodiment 2

[0051] In this embodiment, a kind of Mg thermal reduction prepares black nano-TiO 2 method, including the following steps:

[0052] 1) At room temperature, take an agate mortar, take 0.15g magnesium powder, 0.50g commercial nano-TiO 2 Mix, add 5.00ml of absolute ethanol, grind and mix evenly to obtain mixture A;

[0053] 2) Put the mixture A into a constant temperature drying oven, bake at 90°C for 4 hours, and remove the solvent;

[0054] 3) Put the dried material into a crucible, place it in an argon atmosphere furnace, and calcinate at 600°C for 4 hours at a heating rate and a cooling rate of 5°C / min to obtain sample B;

[0055] 4) Take sample B out, add a hydrochloric acid solution with a mass concentration of 8%, soak for 6 hours, repeat 4 times, filter with deionized water, and wash 4 times;

[0056] 5) Put it into a constant temperature drying oven and dry it at 70°C for 6 hours to obtain black nano-TiO 2 product.

[0057] The prepared black nano-TiO was obtained b...

Embodiment 3

[0059] In this embodiment, a kind of Mg thermal reduction prepares black nano-TiO 2 method, including the following steps:

[0060] 1) At room temperature, take an agate mortar, take 0.23g magnesium powder, 0.50g commercial nano-TiO 2 Mix, add 8.00ml of absolute ethanol, grind and mix evenly to obtain mixture A;

[0061] 2) Put the mixture A into a constant temperature drying oven, bake at 100°C for 4 hours, and remove the solvent;

[0062] 3) Put the dried material into a crucible, place it in an argon atmosphere furnace, set the heating rate and cooling rate at 5°C / min, and calcinate at 550°C for 4h to obtain sample B;

[0063] 4) Take sample B out, add a hydrochloric acid solution with a mass concentration of 8%, soak for 6 hours, repeat 3 times, filter and wash with deionized water 4 times;

[0064] 5) Put the washed sample B into a constant temperature drying oven, and bake it at 80°C for 6 hours to obtain black nano-TiO 2 product.

[0065] The prepared black nano-Ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com