Anti-drift valve devices, blade devices and working machinery

An anti-drift, valve device technology, used in mechanical equipment, accumulator devices, earth movers/shovels, etc., can solve problems such as difficulty in obtaining proper operation of pistons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

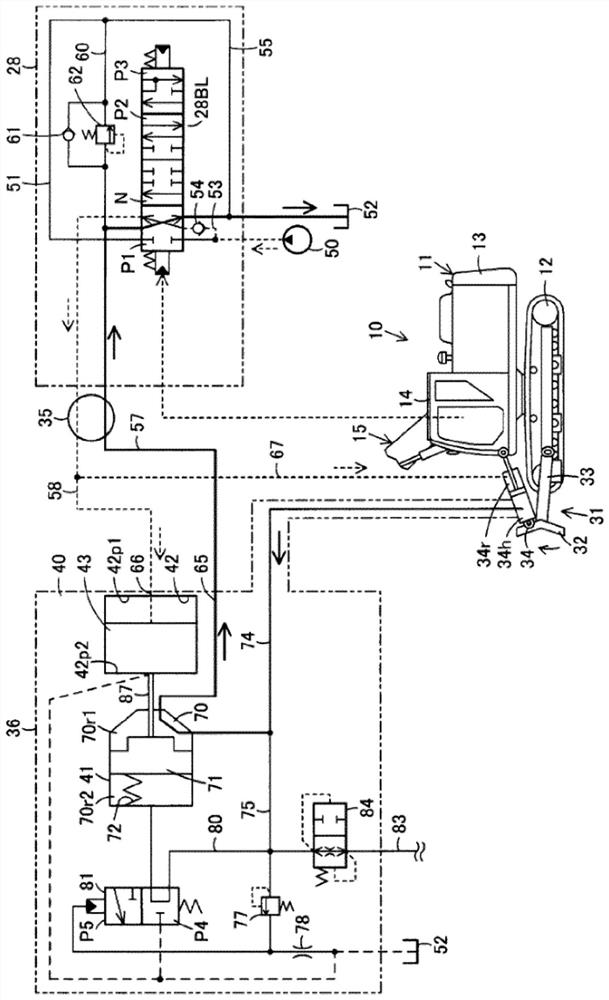

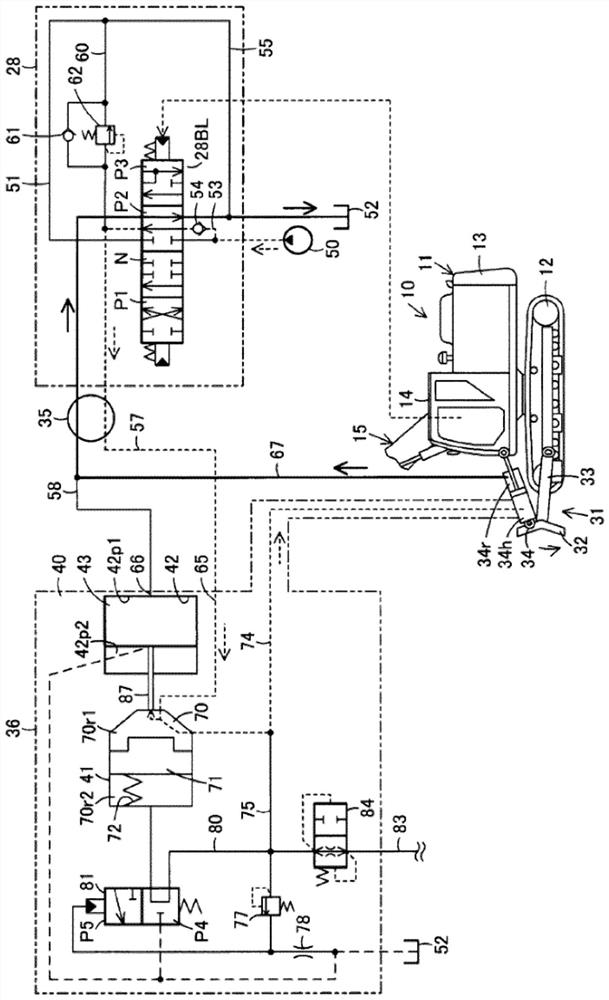

[0045] Below, based on Figure 1 to Figure 7 One embodiment shown describes the invention in detail.

[0046] exist Figure 1 to Figure 6 In , reference numeral 10 denotes a working machine. The working machine 10 of the present embodiment will be described by taking a hydraulic excavator-type working machine as an example.

[0047] The machine tool 10 includes a machine body 11 . In the present embodiment, the upper swing body 13 is provided so as to be swingable on the lower travel body 12 . The lower traveling body 12 may be wheeled or tracked, driven by a traveling engine. The upper swing body 13 is driven by a swing motor. The body 11 includes a cab 14 . The cab 14 is mounted on the upper swing body 13 .

[0048] In addition, the working equipment 15 is supported by the machine body 11 . The working equipment 15 includes: a boom whose base is articulated with the upper swing body 13 so as to be freely rotatable in the vertical direction; an arm serving as a rod ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com