Anti-PID-effect double-sided battery and preparation method thereof

A double-sided battery, effect technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

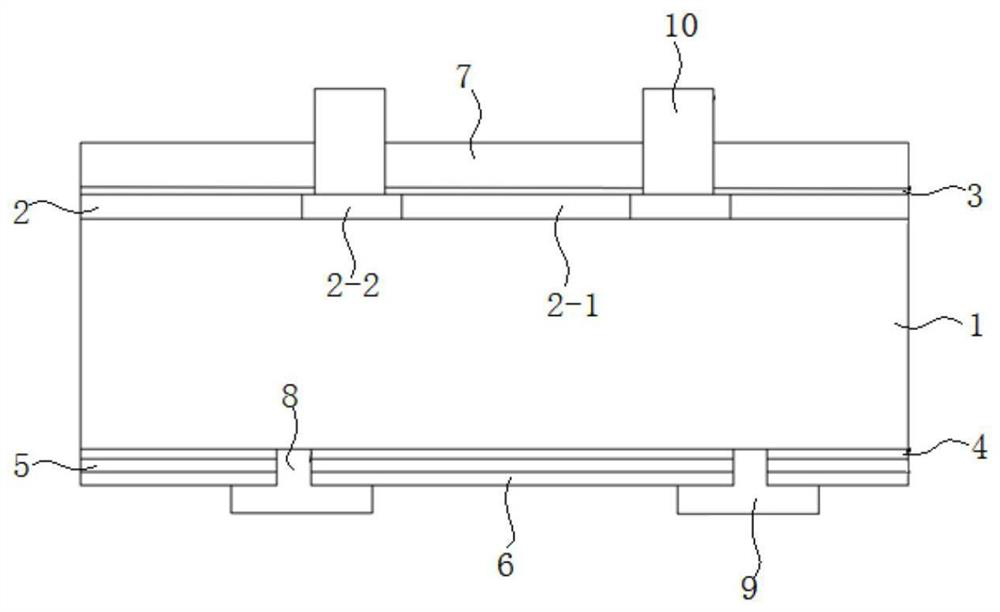

[0048] like figure 1 As shown, the back cell of this embodiment includes a silicon wafer base 1, and the front side of the silicon wafer base 1 is provided with a front emitter 2, a front oxide layer 3, a front silicon nitride passivation and an anti-reflection layer 7 sequentially from bottom to top. And a positive electrode 10, the back of which is provided with an aluminum oxide passivation layer 4, a silicon oxide film 5, a silicon nitride passivation and protection layer 6, and a rear sub-gate electrode 9 in sequence from top to bottom.

[0049] The preparation method of the rear battery of this embodiment specifically includes the following process steps:

[0050] 1. Texture making: use single crystal P-type silicon wafer substrate 1, and use alkali to make texturing on the front and back to form a textured structure.

[0051] 2. Diffusion: React the silicon wafer after texturing with phosphorus oxychloride and the silicon wafer at high temperature to make the front dif...

Embodiment 2

[0070] The structure of the back battery of this embodiment is the same as that of Example 1, and the preparation method of the back battery of this embodiment specifically includes the following process steps:

[0071] 1. Texture making: Single crystal P-type silicon wafers are used, and alkali is used to make texturing on the front and back to form a textured structure.

[0072] 2. Diffusion: React the silicon wafer after texturing with phosphorus oxychloride and the silicon wafer at high temperature to make the front diffuse to form a PN emitter junction 2. Diffusion is carried out by the above-mentioned diffusion process, and the square resistance of the thin layer on the front surface after diffusion is between 150Ω / □.

[0073] 3. Laser SE: use the diffused phosphosilicate glass as the phosphorus source, and perform laser doping on the front side of the diffused silicon wafer and the metallized area corresponding to the positive electrode grid line to form a heavily doped...

Embodiment 3

[0091] The structure of the back battery of this embodiment is the same as that of Example 1, and the preparation method of the back battery of this embodiment specifically includes the following process steps:

[0092] 1. Texture making: use single crystal P-type silicon wafer substrate 1, and use alkali to make texturing on the front and back to form a textured structure.

[0093] 2. Diffusion: React the silicon wafer after texturing with phosphorus oxychloride and the silicon wafer at high temperature to make the front diffuse to form a PN emitter junction (that is, the front emitter 2). Diffusion is carried out by the above-mentioned diffusion process, and the sheet resistance of the thin layer on the front surface after diffusion is between 120 Ω / □.

[0094] 3. Laser SE: use the diffused phosphosilicate glass as the phosphorus source, and perform laser doping on the front side of the diffused silicon wafer and the metallized area corresponding to the positive electrode gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Total thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com