Reactor primary loop dissolved hydrogen content determination method

A measurement method and reactor technology, applied in reactors, nuclear reactor monitoring, measuring devices, etc., can solve problems such as safety risks, complicated inflation process, waste of coolant, etc., to reduce the radiation dose of personnel, protect chemical analysts, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

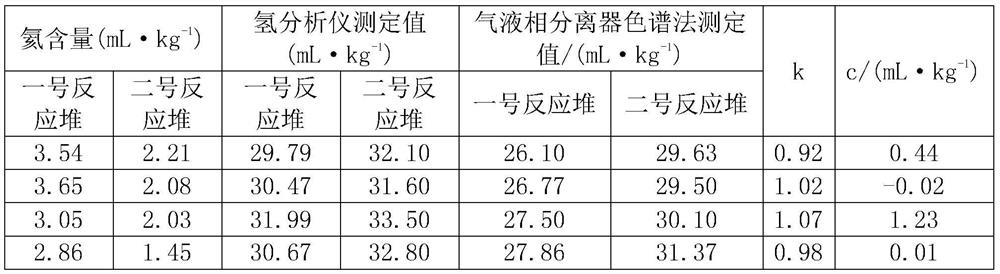

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

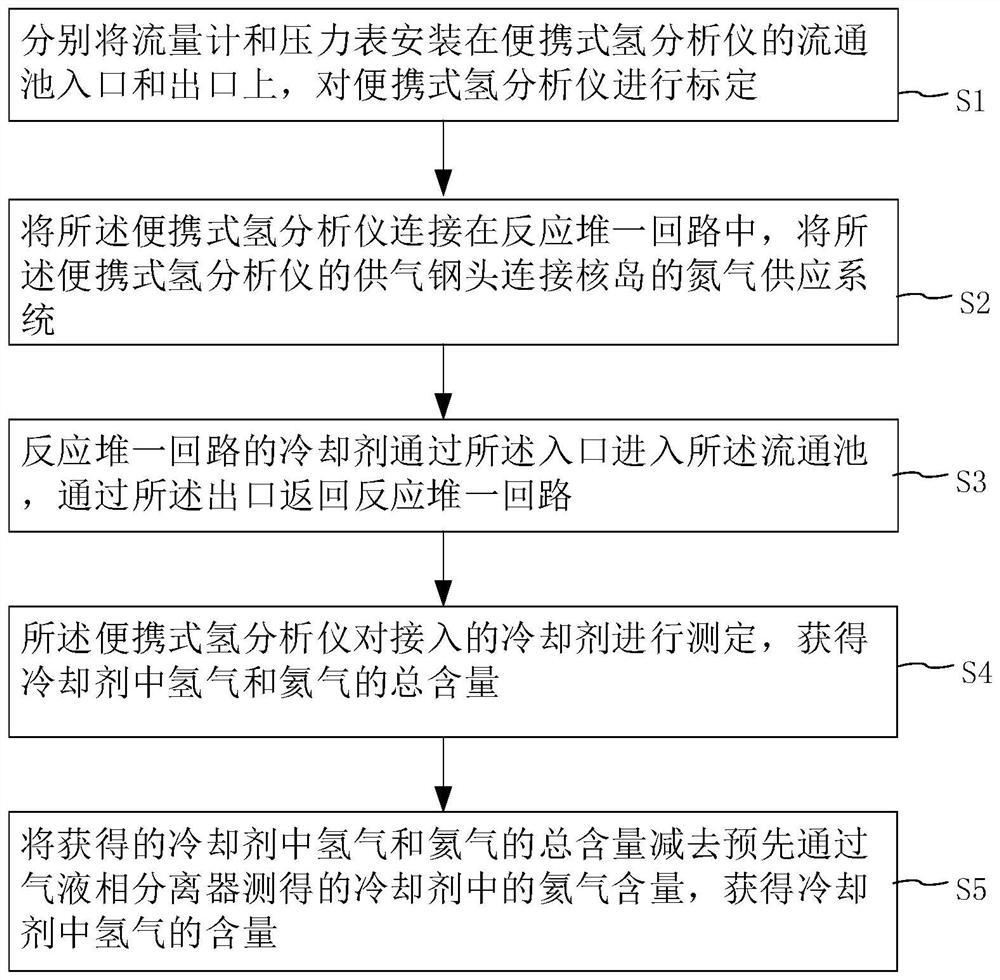

[0032] combine figure 1 , 2 , the reactor primary loop dissolved hydrogen content determination method of an embodiment of the present invention, comprises the following steps:

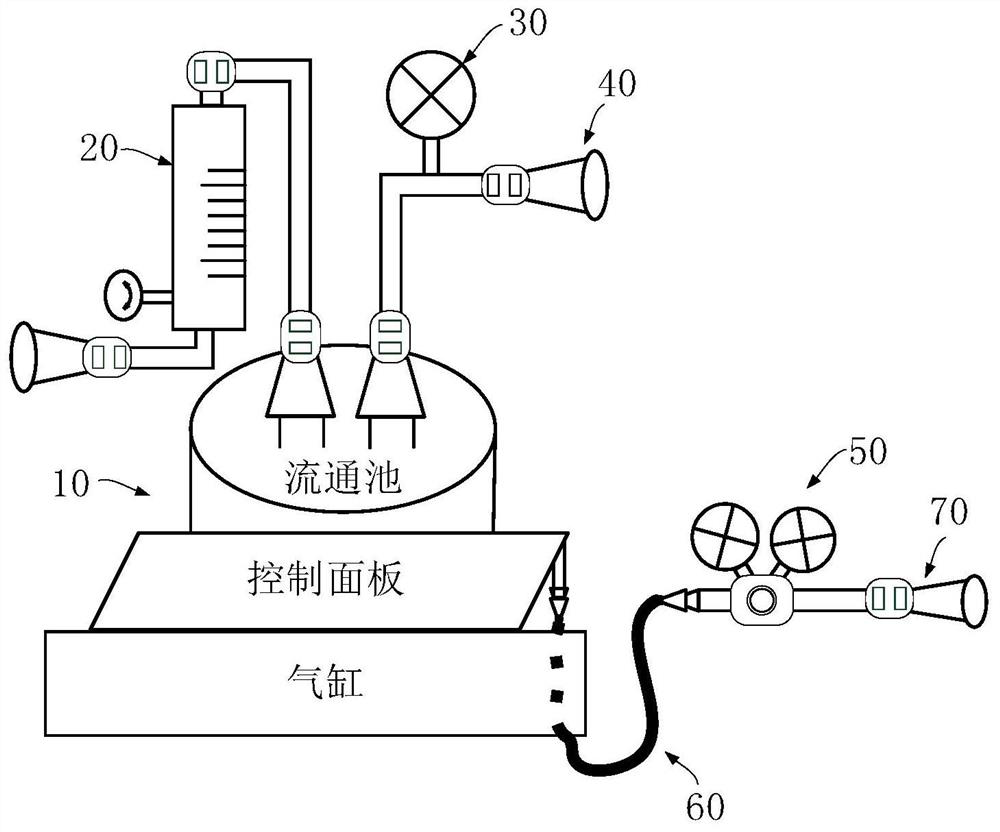

[0033] S1. Install a flow meter 20 at the inlet or outlet of the flow cell of the portable hydrogen analyzer 10 .

[0034] The flow meter 20 is used to monitor the coolant flow into the flow cell; preferably, the flow meter 20 is installed at the inlet of the flow cell.

[0035] Install a pressure gauge 30 at the outlet of the flow cell for monitoring the pressure.

[0036] After the flowmeter 20 and the pressure gauge 30 are installed, the portable hydrogen analyzer 10 is calibrated. The portable hydrogen analyzer can be calibrated using t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com