Football leather and preparation method thereof

A technology of football leather and dry method, which is applied in the field of synthetic leather, can solve the problems of cumbersome steps, complicated preparation process, and unguaranteed wear and scratch resistance, and achieve the goal of reducing separation phenomenon and improving waterproof and wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

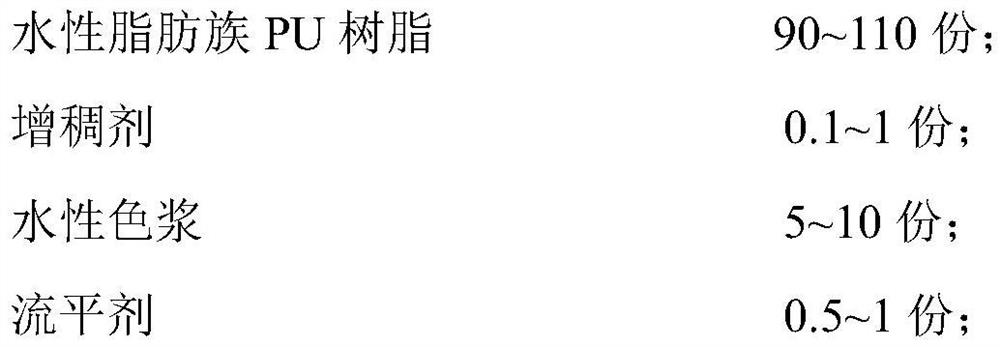

[0038] The football leather provided in this embodiment comprises a base cloth layer, a dry-process PU bottom layer, a dry-process PU middle layer, a water-based non-yellowing PU surface layer and a surface treatment layer arranged in sequence, and the dry-process PU bottom layer of the football leather , The raw material formula of the dry-process PU middle layer and the surface treatment layer is shown in Table 1-2.

[0039] In this example, the base fabric layer is 250g white warp-knitted fabric from Jiangsu Beltford New Material Co., Ltd.

[0040] In this example, the raw materials of the water-based non-yellowing PU surface layer are composed of the following components: 100 parts of Huafon’s JF-PDY-877HY water-based aliphatic PU resin, 8 parts of Maicai’s S19-LR08 water-based color paste, and 0.8 parts of Effie Luo's leveling agent and 0.4 part of Effie's thickener.

[0041] The football leather is prepared through the following steps:

[0042] (1) According to the for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com