Device and method for growing high-quality uniform germanium selenide film

A germanium selenide, thin film technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of thin film chemical composition deviation, expensive sol-gel method, difficult to control stoichiometric ratio, etc. The effect of smooth surface, simple and easy operation of device and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

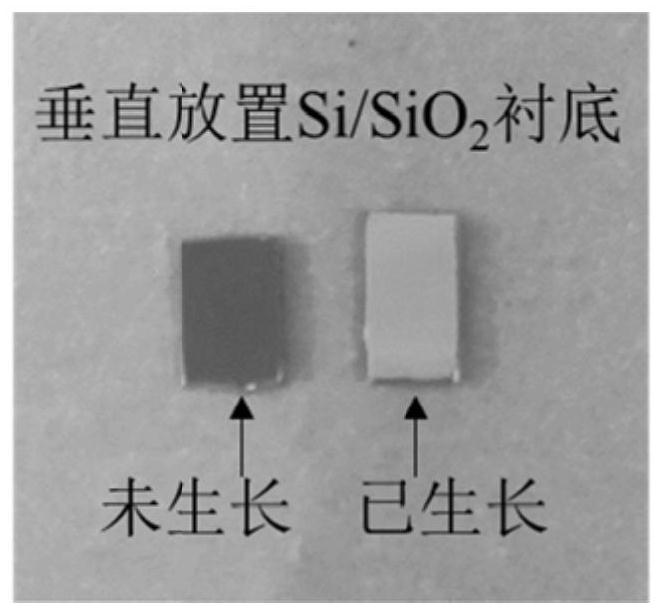

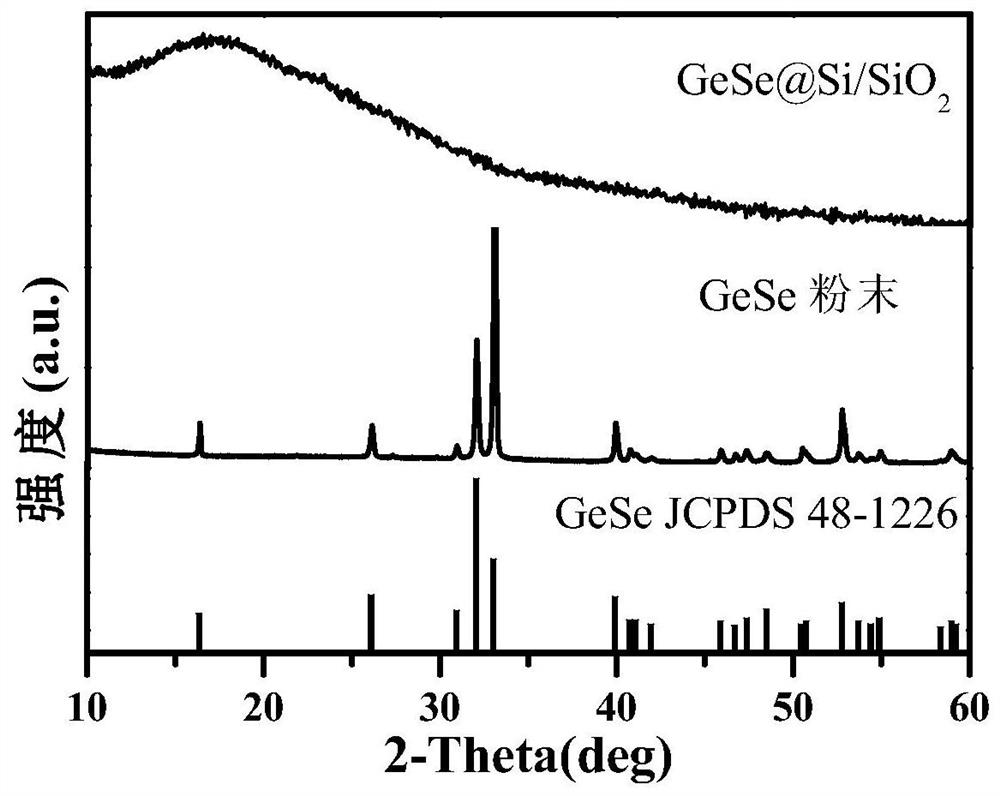

[0045] On Si / SiO 2 Growth of GeSe film with a thickness of 45nm on the substrate:

[0046] Synthetic GeSe powder is first prepared. Weigh metal germanium powder (99.99%) and metal Se powder (99.99%) respectively according to the molar ratio of 1:1, put into the mortar and mix, put the powder of the two directly into the mould, use SPS tabletting, put The original drug powder was prepared and compressed into a cylindrical sample with a height of 2 mm and a diameter of 12.7 mm, and then ground into a powder, which was used as a growth source for gas phase transport.

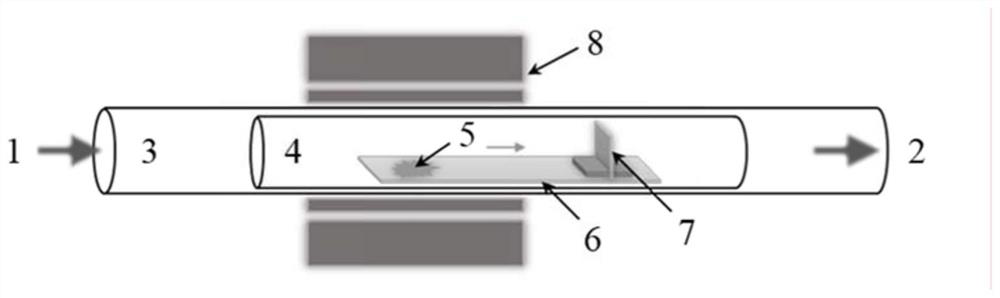

[0047] Place the cleaned built-in Φ50mm quartz tube with a length of 1500mm horizontally in the tube furnace, place a Φ25mm tube with a length of 500mm inside the tube, put a germanium selenide powder growth source at the heating center, and place it downstream of the carrier gas direction perpendicular to the airflow to place a piece of SiO with a thickness of 300nm 2 SiO 2 / Si substrate, SiO 2 Facing the gro...

Embodiment 2

[0058] Growth of GeSe film with a thickness of 60nm on a quartz substrate:

[0059] Synthetic GeSe powder is first prepared. Weigh metal germanium powder (99.99%) and metal Se powder (99.99%) respectively according to the molar ratio of 1:1, put them into a mortar and mix them, put the powders of the two directly into the mold, use SPS to press the powder, and The original drug powder was prepared and compressed into a cylindrical sample with a height of 2 mm and a diameter of 12.7 mm, and then ground into a powder, which was used as a growth source for gas phase transport.

[0060] Place the cleaned built-in Φ50mm quartz tube with a length of 1500mm horizontally in the tube furnace, place a Φ25mm tube with a length of 500mm inside the tube, put a germanium selenide powder growth source at the heating center, and place it in the downstream direction of the carrier gas A quartz substrate is placed in the vertical air flow, and the substrate and the source are placed on the qua...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com