Anti-carburizing treatment method for shaft workpieces

A treatment method and technology for shaft workpieces, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve the problems of increasing the surface of workpieces, corrosion of workpieces, and increasing the cost of anti-seepage agents, so as to save usage, avoid corrosion, Avoid the effects of large-area contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

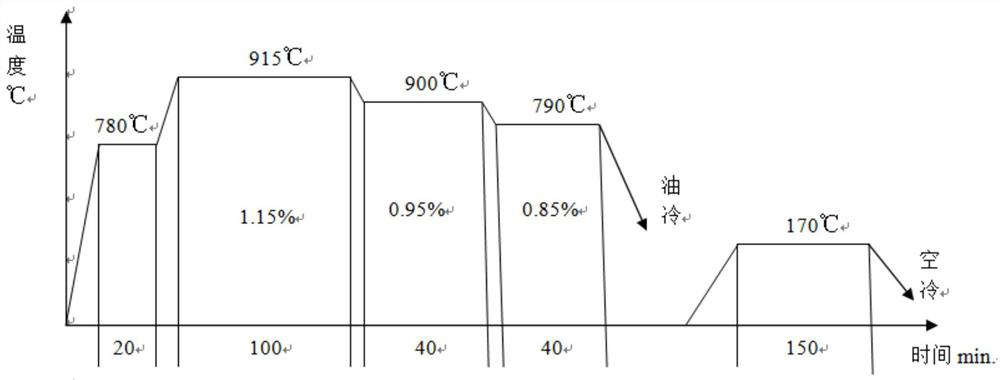

[0024] exist Figure 1 to Figure 5 In the schematic diagram of the present invention shown, the steps of the anti-carburization treatment method for shaft workpieces are as follows:

[0025] Step (1): Make the mandrel: according to the size of the blind hole of the workpiece, make a profiling mandrel, the mandrel is made of 16MnCr5 material, the outer diameter of the chamfer of the mandrel is the same as the inner diameter of the blind hole of the workpiece, and the material of the workpiece is 20CrMnTi , the surface hardness is HRC58-63, the penetration layer depth is 0.6mm, and the inner hole hardness is HRC37-43;

[0026] Step (2): washing: washing the anti-carburization area of the blind hole of the workpiece with a cleaning agent, and then drying;

[0027] Step (3) Furnace loading: After the workpiece is dry, use a soft brush to evenly apply anti-seepage paint on the chamfer of the mandrel, and then install it into the blind hole of the workpiece to seal the blind hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| Circularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com