High-temperature foam profile controlling and flooding agent for offshore thickened oil steam flooding, and application thereof

A technology of flooding agent and steam flooding, which is applied in the direction of production fluid, wellbore/well components, drilling composition, etc. It can solve the problem of high concentration, foam agent can not meet high temperature resistance, and it is difficult to withstand above 300 °C High temperature and other problems, to achieve the effect of increasing the viscosity of the liquid film, good foam stability, and improving the sweep coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

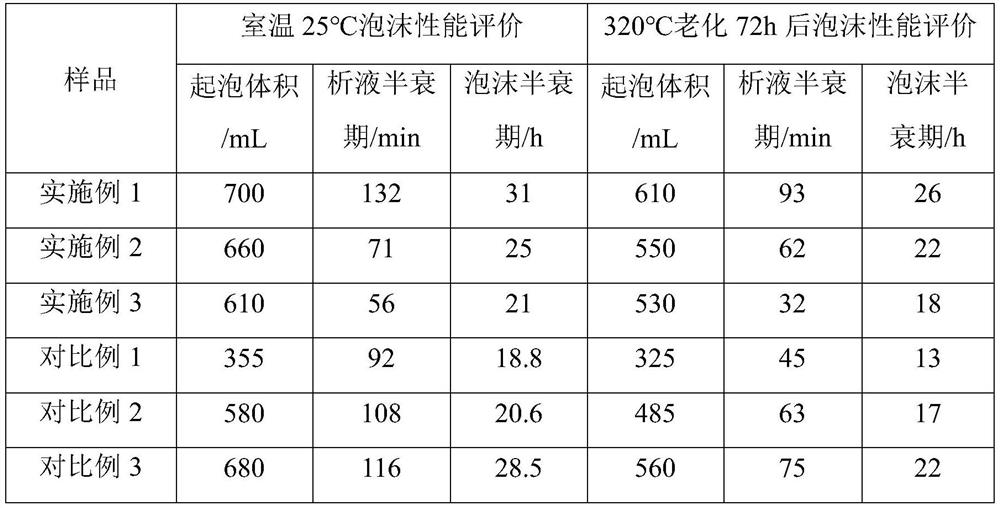

Examples

Embodiment 1

[0032] The mass percentage composition of raw material is as follows:

[0033] Foaming agent 1.0%, nano-modified bentonite (100-300nm particle size) 2%, sodium metaborate 0.05%, water 96.95%;

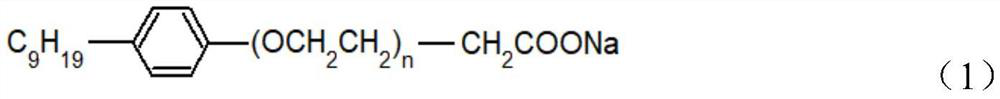

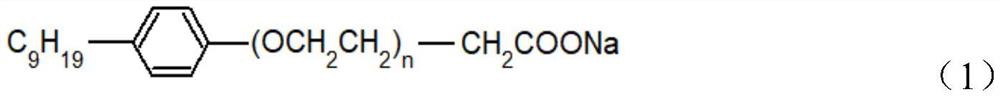

[0034] Among them, the foaming agent is long carbon chain α-olefin sulfonate sodium (C 20 ~C 24 ) and nonylphenol polyoxyethylene ether carboxylate sodium APEC-10 (in formula (1), n=10) in a mass ratio of 3:1.

[0035] Prepare as follows:

[0036] (1) Weigh 2g of nano-modified bentonite, slowly add 96.95g of water under the condition of stirring at 500r / min, increase the speed of rotation at 2000r / min and stir for 2h, so that the nano-modified bentonite is fully expanded and dispersed to form a homogeneous suspension solution, and placed for 10h spare.

[0037] (2) Add 1.0g of foaming agent and 0.05g of sodium metaborate into the nano-modified bentonite particle suspension solution obtained in step (1), and continue to stir at a stirring rate of 100r / min for 30min to obtain high-tem...

Embodiment 2

[0039] The mass percentage composition of raw material is as follows:

[0040] Foaming agent 0.8%, nano-modified bentonite (100-300nm particle size) 1.5%, sodium carbonate 0.05%, water 97.65%;

[0041] Among them, the foaming agent is long carbon chain α-olefin sulfonate sodium (C 20 ~C 24 ) and sodium nonylphenol polyoxyethylene ether carboxylate APEC-15 (in formula (1), n=15) in a mass ratio of 2:1.

[0042] Prepare as follows:

[0043] (1) Weigh 1.5g of nano-modified bentonite, slowly add 97.65g of water under 500r / min stirring condition, increase the rotating speed of 1500r / min and stir for 2h, make the nano-modified bentonite fully expand and disperse, form a homogeneous suspension solution, place 12h standby.

[0044] (2) Add 0.8g of foaming agent and 0.05g of sodium carbonate into the nano-modified bentonite particle suspension solution obtained in step (1), and continue to stir at a stirring rate of 150r / min for 20min to obtain a high-temperature foam control agent...

Embodiment 3

[0046] The mass percentage composition of raw material is as follows:

[0047] Foaming agent 0.5%, nano-modified bentonite (100-300nm particle size) 1.0%, sodium bicarbonate 0.05%, water 98.45%;

[0048] Among them, the foaming agent is long carbon chain α-olefin sulfonate sodium (C 20 ~C 24 ) and nonylphenol polyoxyethylene ether carboxylate sodium APEC-20 (in formula (1), n=20) in a mass ratio of 1:1 compound.

[0049]Prepare as follows:

[0050] (1) Weigh 1.0g of nano-modified bentonite, slowly add 98.45g of water under 500r / min stirring condition, increase the rotating speed of 1800r / min and stir for 2h, so that the nano-modified bentonite is fully expanded and dispersed to form a homogeneous suspension solution, place 8h standby.

[0051] (2) Add 0.5g foaming agent and 0.05g sodium bicarbonate to the nano-modified bentonite particle suspension solution obtained in step (1), and continue to stir at a stirring rate of 200r / min for 10min to obtain high-temperature foam c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com