Novel coal mine foam dedusting agent

A technology of dust remover and coal mine, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems such as unsatisfactory effect, achieve remarkable thickening effect, bactericidal enzyme activity, and water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

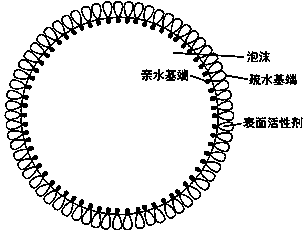

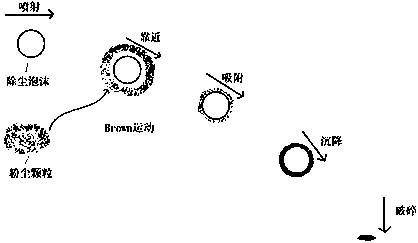

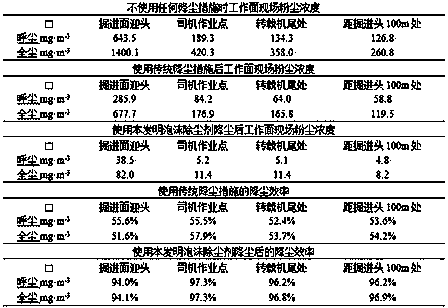

[0023] Take 8g of lauryl glucoside, 0.2g of polyanionic cellulose, and 4g of alkylphenol polyoxyethylene ether, add them to 987.8g of water, mix well, heat it slightly to dissolve completely, and finally configure 1kg of foam dust remover. In this foam dust remover, the proportion of lauryl glucoside is 0.8%, the proportion of polyanionic cellulose is 0.02%, and the proportion of alkylphenol ethoxylate is 0.4%. Its specific dust reduction principle is shown in Figure 1 and Figure 2. Add the prepared foam dedusting agent into the Roche Foam Instrument Generator to produce a foam height of 862.73mL. Enlarging the mass of the foam dust remover by 100 times to prepare a foam dust remover, adding the prepared foam dust remover to the mine foam generator, transporting the generated foam to the dust source and covering the dust source can achieve a good dust reduction effect. The total dust reduction rate of the formula can reach 97.27%, and the exhaled dust reduction rate can reach...

Embodiment 2

[0025] Take 8.5g of fatty alcohol polyoxyethylene ether, 0.2g of polyanionic cellulose, and 4.5g of alkylphenol polyoxyethylene ether, add them into 986.8g of water, mix well, heat it slightly to dissolve completely, and finally configure 1kg of foam dust remover. In the foam dust remover, the proportion of fatty alcohol polyoxyethylene ether is 0.85%, the proportion of polyanionic cellulose is 0.02%, and the proportion of alkylphenol polyoxyethylene ether is 0.45%. Its specific dust reduction principle is shown in Figure 1 and Figure 2. Add the prepared foam dedusting agent into the Roche foam generator to generate a foam height of 453.33mL, and increase the mass of the foam dedusting agent by 100 times to prepare the foam dedusting agent, and add the prepared foam dedusting agent into the mine foam generator , Transport the generated foam to the dust source and cover the dust source to achieve a good dust reduction effect. The total dust reduction rate of this formula can re...

Embodiment 3

[0027] Take 2g of fatty alcohol polyoxyethylene ether, 0.2g of polyanionic cellulose, and 8g of lauryl glucoside, add it to 989.8g of water, mix well, heat it slightly to dissolve completely, and finally configure 1kg of foam dust remover. In the foam dust remover, the proportion of fatty alcohol polyoxyethylene ether glucoside is 0.2%, the proportion of polyanionic cellulose is 0.02%, and the proportion of lauryl glucoside is 0.8%. Its specific dust reduction principle is shown in Figure 1 and Figure 2. Add the prepared foam dedusting agent into the Roche foam generator to generate a foam height of 586.67mL, and increase the mass of the foam dedusting agent by 100 times to prepare the foam dedusting agent, and add the prepared foam dedusting agent into the mine foam generator. Transporting the generated foam to the dust source and covering the dust source can achieve a good dust reduction effect. The total dust reduction rate of this formula can reach 82.73%, and the dust red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com