Injection mold based on environment-friendly plastic processing

A technology for injection molds and environmentally friendly plastics, which is applied in the field of injection molds based on environmentally friendly plastic processing, and can solve problems such as poor product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

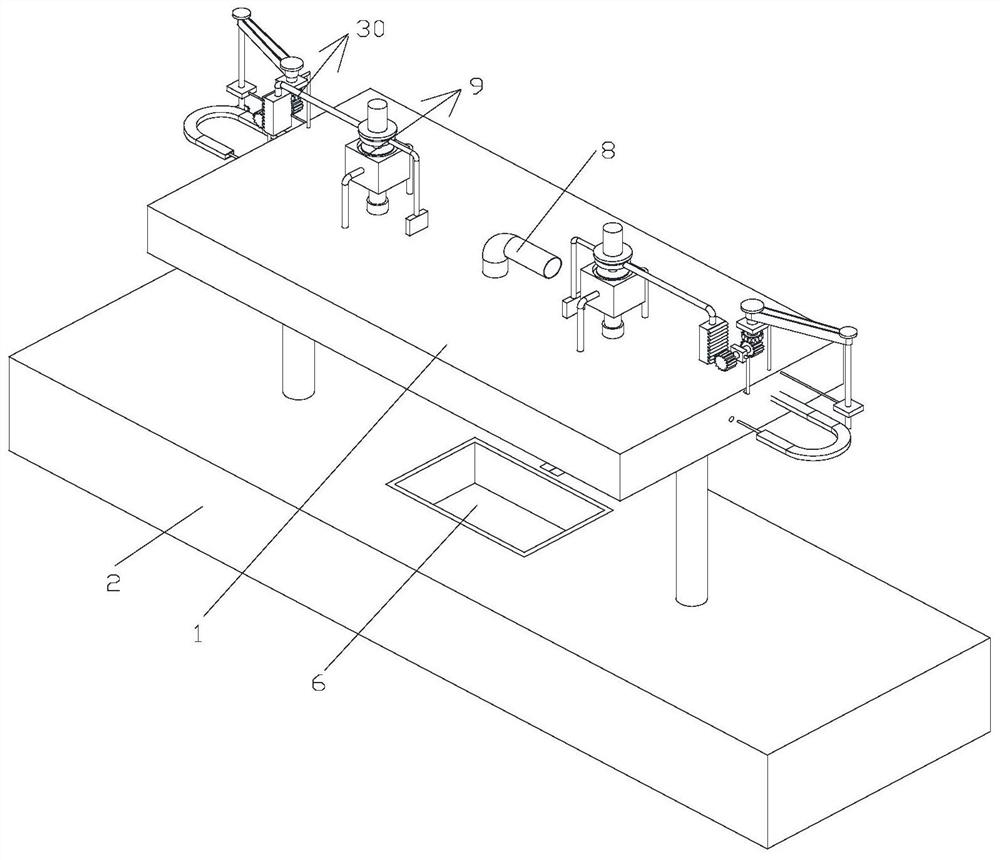

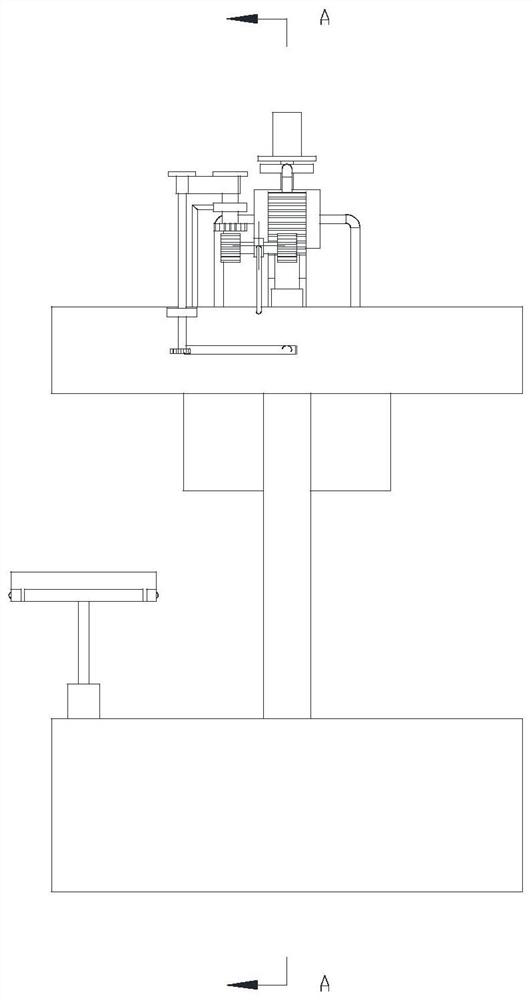

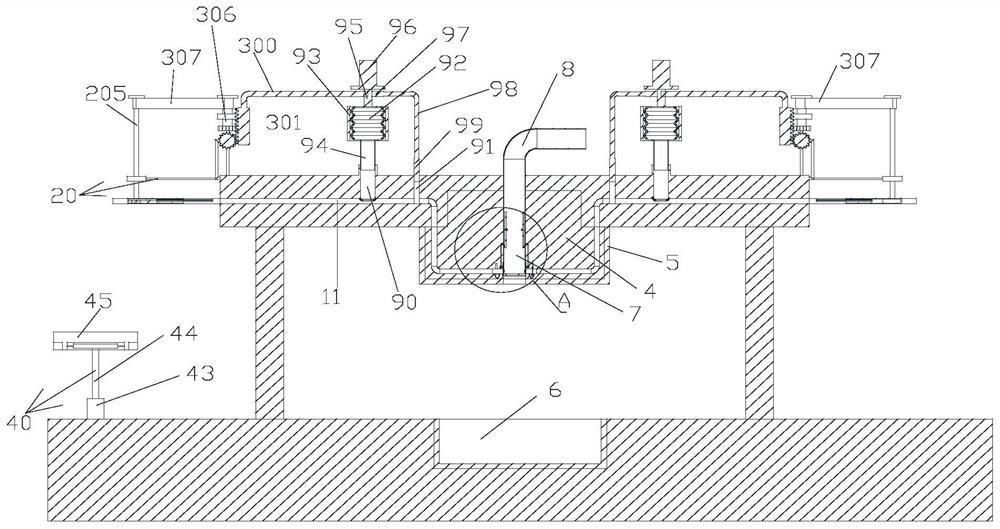

[0032] Such as Figure 1-13As shown, an injection mold based on environmentally friendly plastic processing includes an upper mold 1, a lower mold 2, a release column 3, a fixed seat 4, an upper mold base 5, a lower mold base 6, an injection channel 7 and an injection pipeline 8; The lower mold 2 is arranged below the upper mold 1; the stripping column 3 is arranged between the upper mold 1 and the lower mold 2; technology, which will not be repeated here; the upper mold base 5 is sleeved outside the fixed base 4; the injection channel 7 is used to communicate with the upper mold base 5 and the fixed base 4; the injection pipeline 8 is located in the injection channel 7 .

[0033] The injection channel 7 is provided with an exhaust device 70, and the exhaust device 70 includes a ring groove 71, a first limiting groove 72, a second limiting groove 73, a first plate body 74, a second plate body 75, The second connecting rod 76; the ring groove 71 is opened in the circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com