A 3D printing equipment leveling system and automatic leveling method thereof

A 3D printing and equipment technology, applied in the field of 3D printing equipment leveling system, can solve the problems of wasting time, unable to eliminate subtle errors, unable to guarantee the leveling accuracy, etc., to achieve high measurement accuracy, accurate leveling process, leveling Process stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

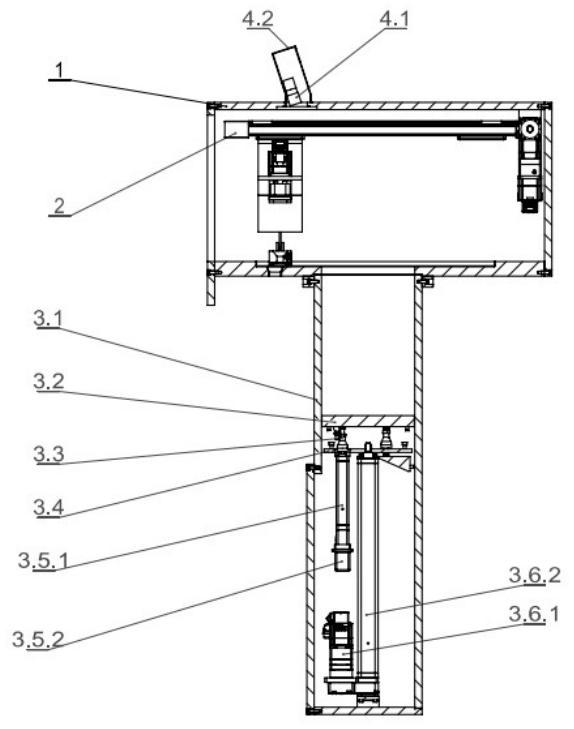

[0055] Such as figure 1As shown, the present invention provides a technical solution: a 3D printing equipment leveling system and leveling method, including a working chamber 1, a powder spreading device 2, a forming part lifting device 3, an image acquisition device 4 and a data processing device.

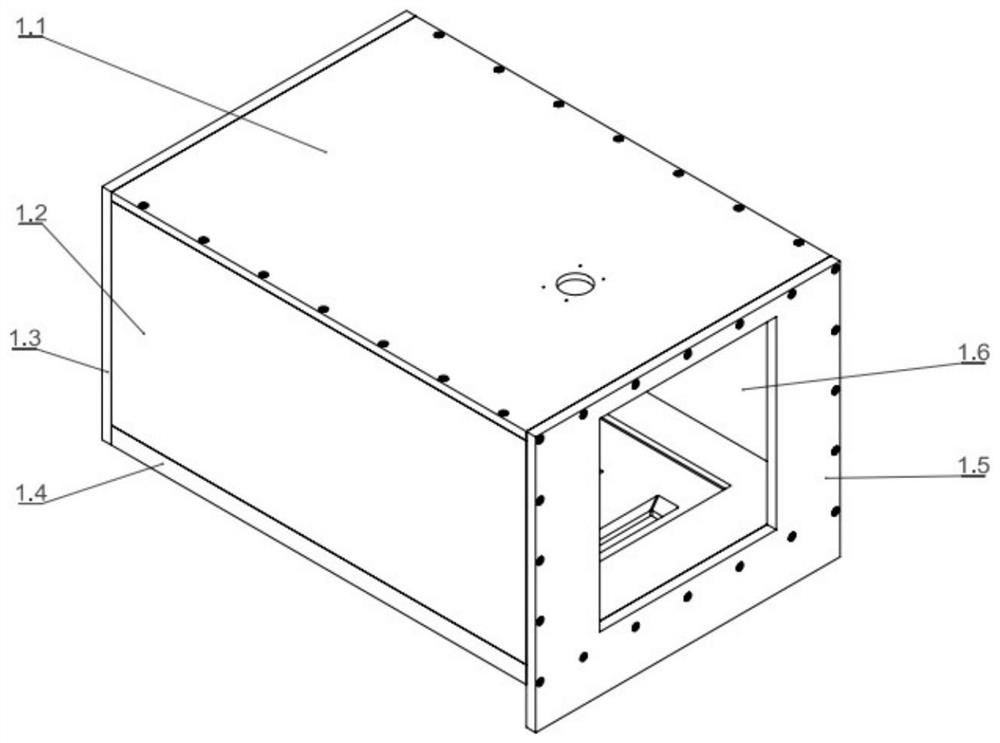

[0056] Such as figure 2 As shown, the working chamber 1 includes a working platform 1.4, a working chamber roof 1.1, a working chamber left vertical board 1.2, a working chamber right vertical board 1.6, a working chamber front vertical board 1.5, and a working chamber rear vertical board 1.3.

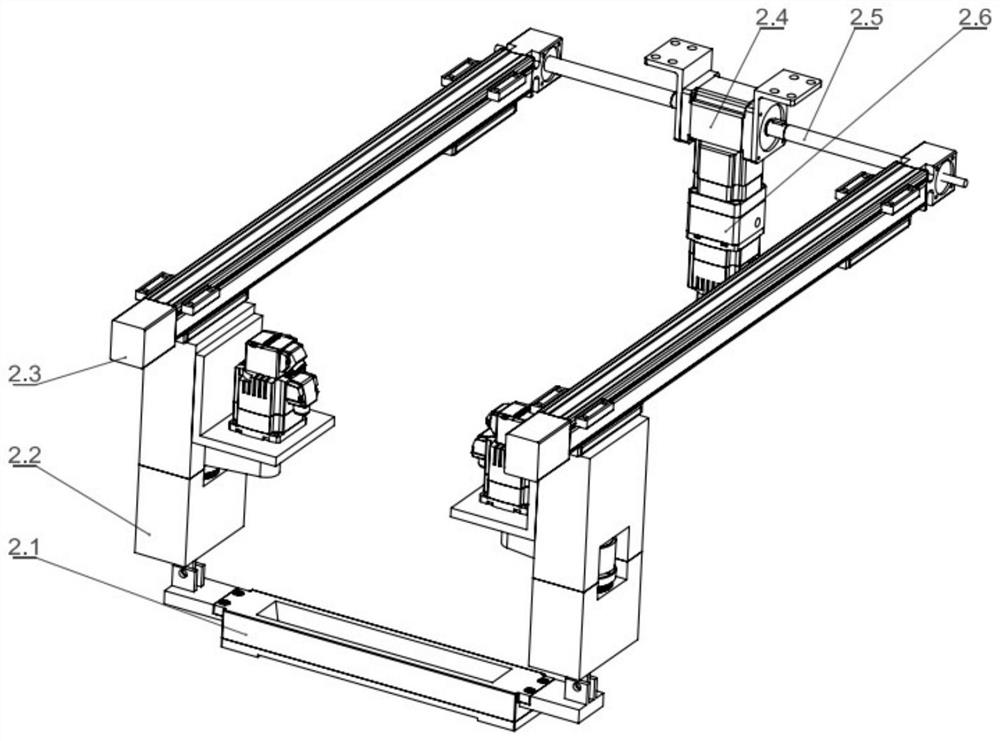

[0057] Such as image 3 , Figure 4 , Figure 5 As shown, the powder spreading device includes a tool holder 2.1, a posture adjustment unit 2.2, a driving guide rail 2.3, a reducer 2.4, an adapter shaft 2.5, and a driving motor 2.6. The knife holder 2.1 includes the upper body 2.1.1 of the knife holder, the lower body 2.1.2 of the knife holder, the scraper 2.1.3, the scraper pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com