Production method of alloy spring steel wire with excellent drawing performance

A production method and spring steel technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of increasing spheroidizing or softening annealing process, energy consumption, long cycle, etc., to increase the driving force of phase change and Effects of phase transformation nuclei, shortening phase transformation incubation period, and increasing substructure density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

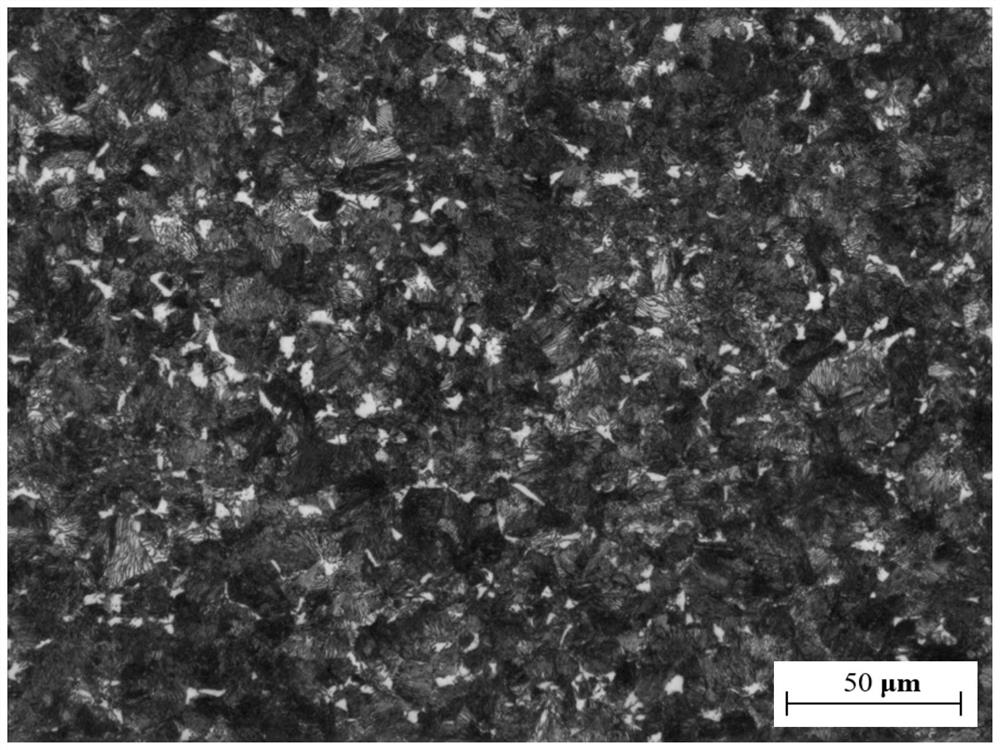

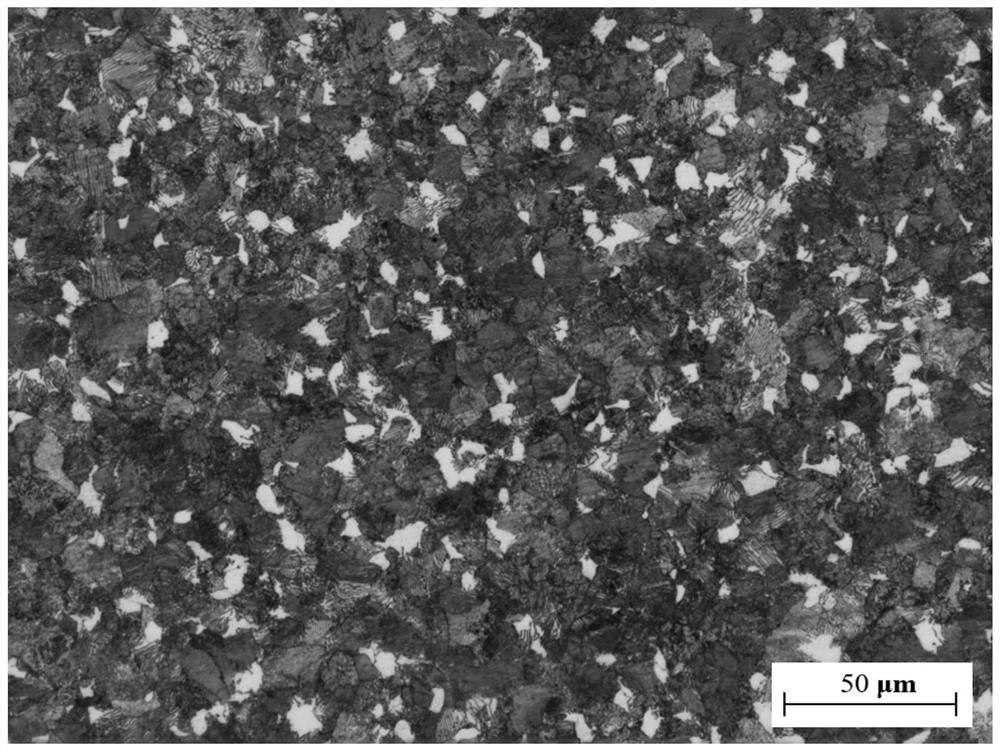

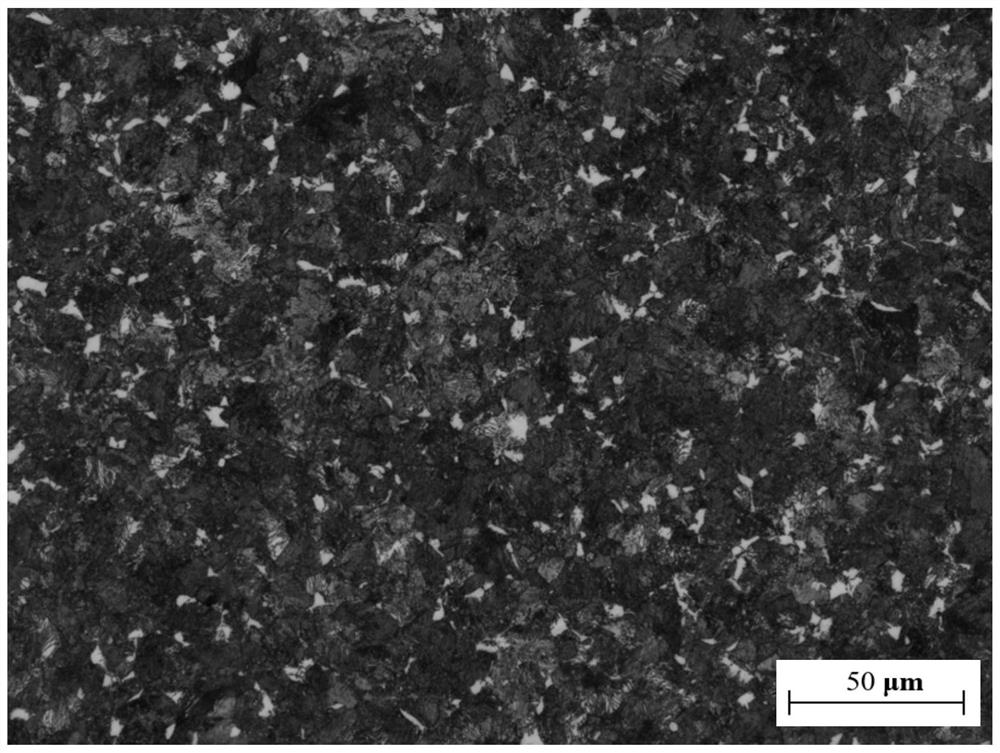

Image

Examples

Embodiment 1

[0026] Example 1 (Φ6.5mm)

[0027] 1. Steel billet 220*260 is heated and opened

[0028] The composition of the billet is calculated by mass percentage (wt%). The composition is C: 0.50, Si: 0.25, Mn: 0.75, P: 0.012, S: 0.008, Cr: 1.05, Ni: 0.02, Cu: 0.02, Al: 0.020, V: 0.15, the rest is Fe.

[0029] The total heating time of the steel slab in the heating furnace is 362 minutes, the high-temperature diffusion time of the second heating stage and the soaking section of the billet is 198 minutes, and the temperature of the second heating stage and the soaking section is 1212-1235°C.

[0030] 2. Intermediate billet 160*160 heating

[0031] The temperature of the second heating stage and the soaking section of the intermediate billet is 1012-1050°C, the total heating time is 163 minutes, the second heating stage and the soaking section are 81 minutes, and the air-fuel ratio is 0.43-0.50.

[0032] 3. Rolling

[0033] The billet starts rolling at a temperature of 923-935°C. The ...

Embodiment 2

[0038] Example 2 (Φ9.0mm)

[0039] 1. Steel billet 220*260 is heated and opened

[0040] The composition of the billet is calculated by mass percentage (wt%). The composition is C: 0.50, Si: 0.25, Mn: 0.75, P: 0.012, S: 0.008, Cr: 1.05, Ni: 0.02, Cu: 0.02, Al: 0.020, V: 0.15, the rest is Fe. The total heating time of the steel slab in the heating furnace is 435 minutes, the high temperature diffusion time of the second heating section and the soaking section of the cast slab is 232 minutes, and the temperature of the second heating section and the soaking section is 1223-1246°C.

[0041] 2. Intermediate billet 160*160 heating

[0042] The temperature of the second heating stage and the soaking section of the intermediate billet is 1023-1049°C, the total heating time is 190 minutes, the second heating stage and the soaking section are 95 minutes, and the air-fuel ratio is 0.46-0.50.

[0043] 3. Rolling

[0044] The billet start rolling temperature is 939-954°C, the rolled p...

Embodiment 3

[0049] Example 3 (Φ12mm)

[0050] 1. Steel billet 220*260 is heated and opened

[0051]The composition of the billet is calculated by mass percentage (wt%). The composition is C: 0.51, Si: 0.25, Mn: 0.73, P: 0.010, S: 0.005, Cr: 1.02, Ni: 0.02, Cu: 0.02, Al: 0.025, V: 0.13, the rest is Fe. The total heating time of the steel slab in the heating furnace is 435 minutes, the high-temperature diffusion time of the second section of the casting slab heating and the soaking section is 232 minutes, and the temperature of the high-temperature section is 1223-1246°C.

[0052] 2. Intermediate billet 160*160 heating

[0053] The temperature of the second heating stage and the soaking section of the intermediate blank is 1013-1039°C, the total heating time is 174 minutes, the second heating stage and the soaking section are 82 minutes, and the air-fuel ratio is 0.46-0.50.

[0054] 3. Rolling

[0055] The billet start rolling temperature is 919-944°C, the rolled piece is cooled by wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com