Fast-assembly filter plate

A filter plate and plate body technology, applied in the field of water treatment, can solve the problems of difficulty in controlling the flatness of the plate bottom, large seam height difference, and easy air leakage at the seam, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

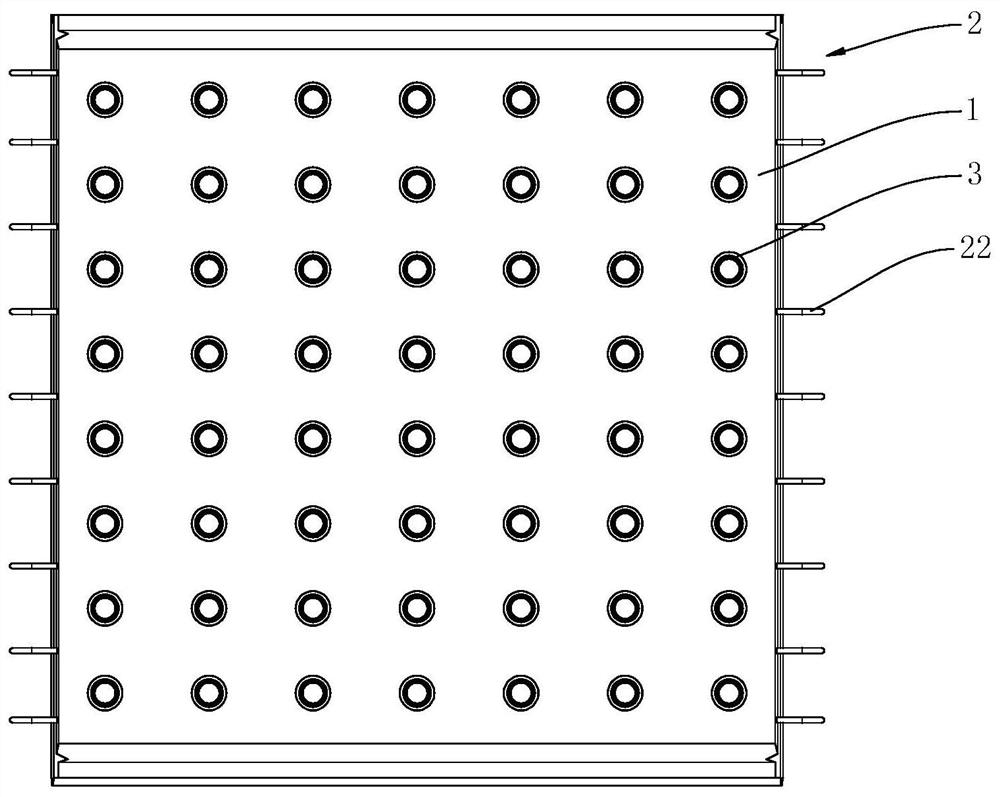

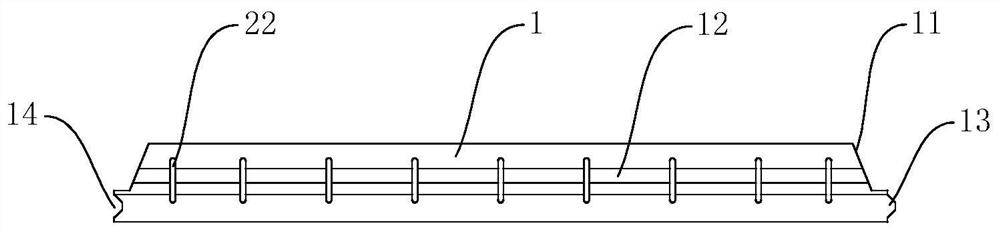

[0022] The fast packing filter plate of embodiment 1, as Figure 1-Figure 3 As shown, it includes a square concrete slab body 1, steel skeleton 2 and several embedded parts 3, several embedded parts 3 are used to install long handle filter heads (not shown in the figure), steel skeleton 2 and several embedded parts 3 They are respectively arranged in the concrete slab body 1, and the side edges of the reinforcement skeleton 2 are exposed on the four sides of the concrete slab body 1, and each side of the concrete slab body 1 is a slope 11 inclined from top to bottom to the outside.

[0023] In Embodiment 1, the reinforcement frame 2 is a reinforcement cage formed by binding several reinforcement bars 21 criss-crossing horizontally and vertically. Iron wires (not shown in the figure) are bound at the intersections of the horizontal and vertical reinforcement bars 21. The side edges of the reinforcement frame 2 include A plurality of arc-shaped sections 22 arranged at intervals,...

Embodiment 2

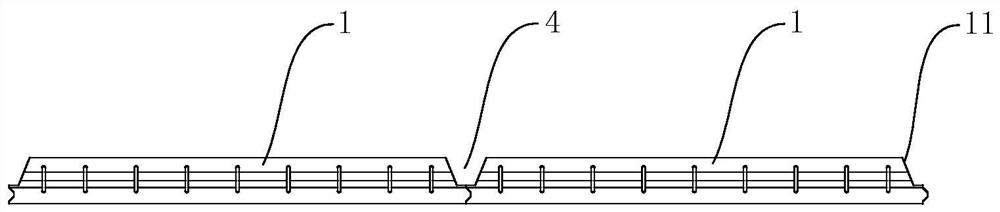

[0026] The quick packing filter plate of embodiment 2, the difference with embodiment 1 is, in embodiment 2, as Figure 4-Figure 5 As shown, no tenons and tenons are designed on the concrete slab body 1 . When splicing the quick-installed filter plates of Example 2 on site, after lining the bottom of each concrete plate body 1 with a mold (not shown in the figure), first make the exposed steel bars of the adjacent two concrete plate bodies 1 The side edges of the skeleton 2 are staggered and stuck, and then concrete mortar is poured at the joints of two adjacent concrete slab bodies 1 .

Embodiment 3

[0027] The fast packing filter plate of embodiment 3, the difference with embodiment 2 is, in embodiment 3, such as Figure 6-Figure 9 As shown, the side edge of the concrete slab body 1 is not provided with grooves. The splicing method of the quick-pack filter plate in Example 3 is the same as that of the quick-pack filter plate in Example 2.

[0028] In practical application, taking a square concrete slab as an example, its structure can be steel bars exposed on four sides, as in Example 3; it can also be steel bars exposed on three sides, which is more common in the case of connecting with filter tank beams. The surface that does not expose the steel bar just rides on the beam and fixes; it can also be that the steel bar is exposed on both sides, as in Embodiment 1. It depends on the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com