Gas stripping device and aerated grit chamber

A technology of aeration, sand settling and air lift, which is applied to the feeding/discharging device of the settling tank, settling tank, sedimentation and separation, etc. It can solve the problems of low degree of independent monitoring of equipment, frequent equipment maintenance, and low work efficiency. Achieve the effects of reducing personnel operating costs, reducing the probability of blocking, and reducing the intensity of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

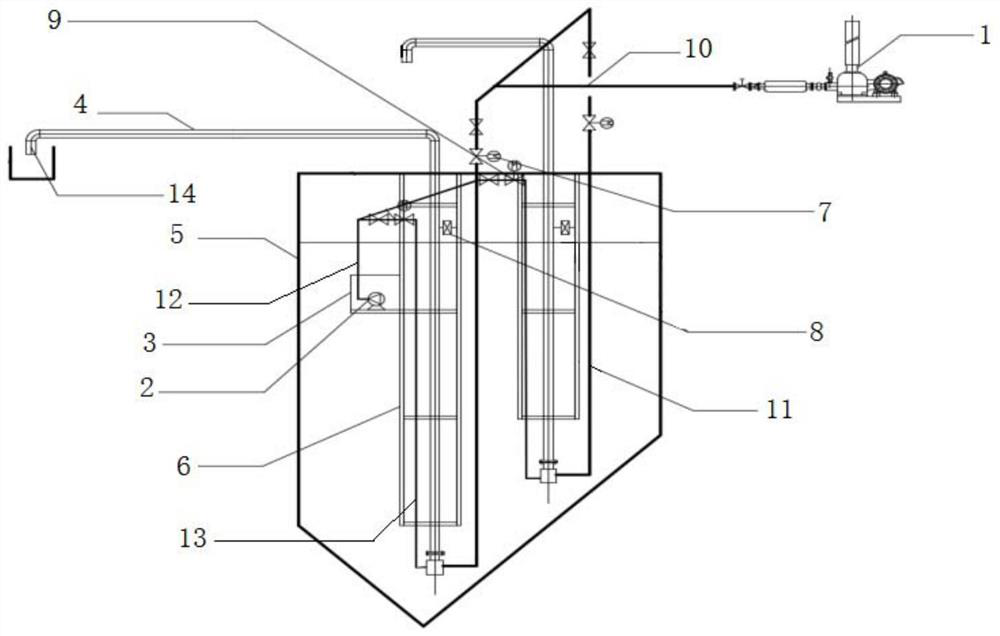

[0073] Such as figure 1 As shown, the invention provides a kind of gas stripping device, comprising:

[0074] Fan 1;

[0075] Rinse pump 2;

[0076] Two sand outlet pipes 4, one end is used to be arranged in the aeration grit chamber 5, the sand outlet pipe 4 is provided with a monitoring module, the monitoring module can monitor the sand outlet state and the lateral force state of the sand outlet pipe 4;

[0077] An air duct, one end of which is connected to one end of the sand outlet pipe 4, and the other end of the air duct is connected to the fan 1, and the air duct is provided with a gas control valve 7;

[0078] A flushing pipe, one end of which is connected to one end of the sand outlet pipe 4, the other end of the flushing pipe is connected to the flushing pump 2, and a flushing control valve 9 is arranged on the flushing pipe;

[0079] The control unit is connected with the monitoring module, the gas control valve 7 and the flushing control valve 9 .

[0080] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com