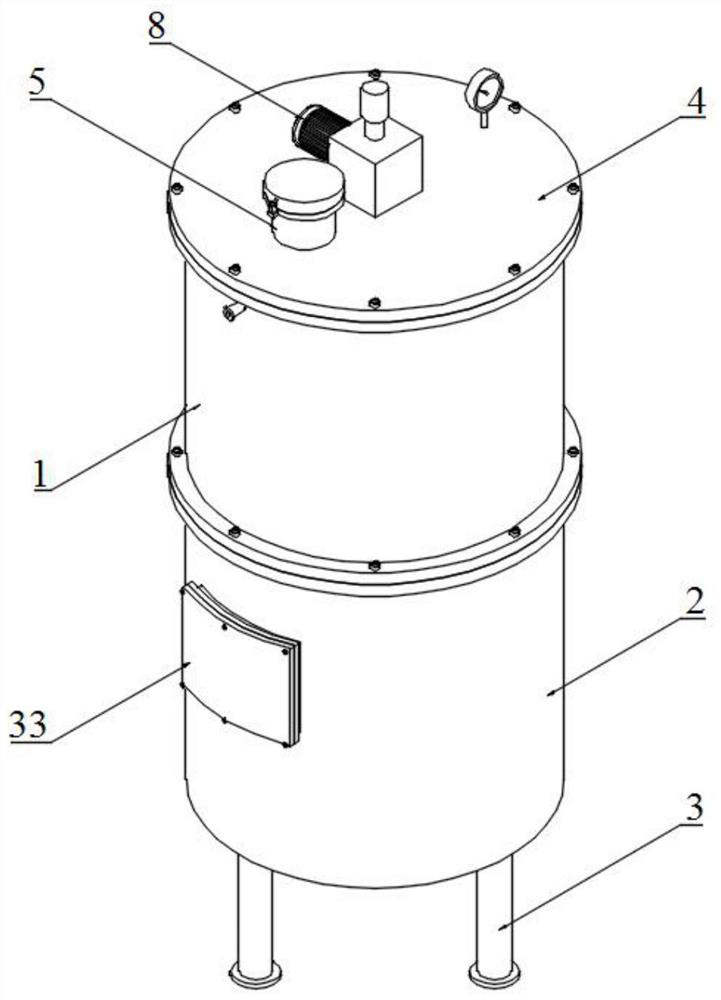

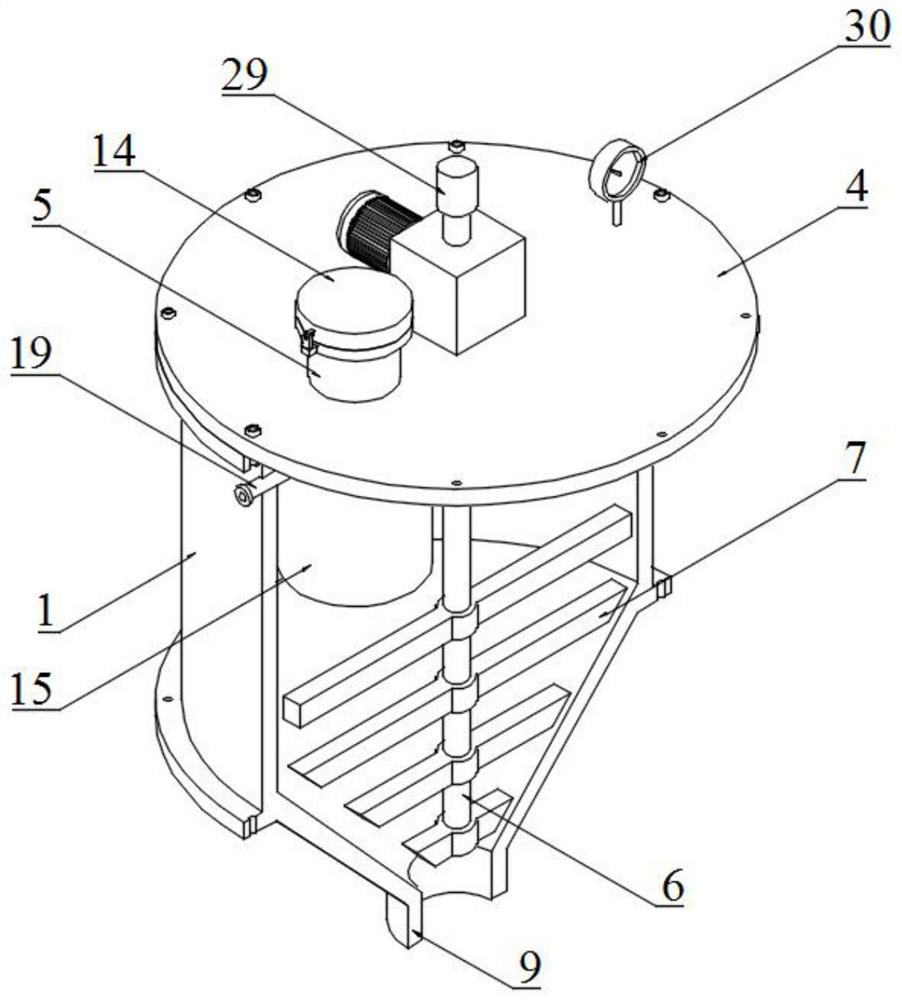

Pig feed processing device and method

A processing device and pig feed technology, applied in feed, animal feed, animal feed, etc., can solve the problems of insufficient mixing of raw materials, affecting feed quality, poor mixing effect, etc., to improve mixing effect, significant economic benefits, and improve lean The effect of meat rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A pig feed processing method, the pig feed comprises the following raw materials in parts by weight: 8 parts of soybean oil, 30 parts of corn, 40 parts of soybeans, 10 parts of rice bran, 5 parts of fish meal, 5 parts of table salt, 3 parts of compound amino acids, 3 parts of compound vitamins, gallbladder 0.5 part of alkali, 1 part of antioxidant and 50 parts of water, the compound amino acid is composed of lysine, methionine and threonine, and the compound vitamin is composed of vitamin A, vitamin B1, vitamin B, vitamin B6, vitamin B12, vitamin C and vitamin D , vitamin E composition, described pig feed processing method comprises the following steps:

[0039] S1. Grinding corn, soybeans and rice bran to 80 mesh through a pulverizer, and then mixing soybean oil with the above-mentioned raw material powders in proportion for later use;

[0040] S2. Add the mixed powder raw material prepared in step S1 into the mixing tank through the feed pipe, and add 80°C hot water i...

Embodiment 2

[0044] A pig feed processing method, the pig feed comprises the following raw materials in parts by weight: 15 parts of soybean oil, 40 parts of corn, 60 parts of soybeans, 20 parts of rice bran, 10 parts of fish meal, 8 parts of table salt, 5 parts of compound amino acids, 5 parts of compound vitamins, gallbladder 2 parts of alkali, 3 parts of antioxidant and 120 parts of water, the compound amino acid is composed of lysine, methionine and threonine, and the compound vitamin is composed of vitamin A, vitamin B1, vitamin B, vitamin B6, vitamin B12, vitamin C and vitamin D , vitamin E composition, described pig feed processing method comprises the following steps:

[0045] S1. Grinding corn, soybeans and rice bran to 120 mesh through a pulverizer, and then mixing soybean oil with the above-mentioned raw material powders in proportion to stand-by;

[0046] S2. Put the mixed powder raw material prepared in step S1 into the mixing tank through the feed pipe, and put 100°C hot wate...

Embodiment 3

[0050] A pig feed processing method, the pig feed comprises the following raw materials in parts by weight: 12 parts of soybean oil, 35 parts of corn, 45 parts of soybeans, 15 parts of rice bran, 8 parts of fish meal, 6 parts of table salt, 4 parts of compound amino acids, 4 parts of compound vitamins, gallbladder 1.2 parts of alkali, 2 parts of antioxidant and 100 parts of water, the compound amino acid is composed of lysine, methionine and threonine, and the compound vitamin is composed of vitamin A, vitamin B1, vitamin B, vitamin B6, vitamin B12, vitamin C and vitamin D , vitamin E composition, described pig feed processing method comprises the following steps:

[0051] S1. Grinding corn, soybeans and rice bran to 100 mesh through a pulverizer, and then mixing soybean oil with the above-mentioned raw material powders in proportion for later use;

[0052] S2. Add the mixed powder raw material prepared in step S1 into the mixing tank through the feeding pipe, and add 90°C hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com