Natural fire-reducing sweetness base material and preparation method thereof

A base material and sweetness technology, applied in food ingredients containing natural extracts, bacteria used in food preparation, functions of food ingredients, etc., can solve the problems of increasing the incidence of obesity and diabetes, increasing the burden of liver decomposition, and increasing the probability of dental caries and other problems, to reduce the risk of getting angry, soft taste, and improve the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

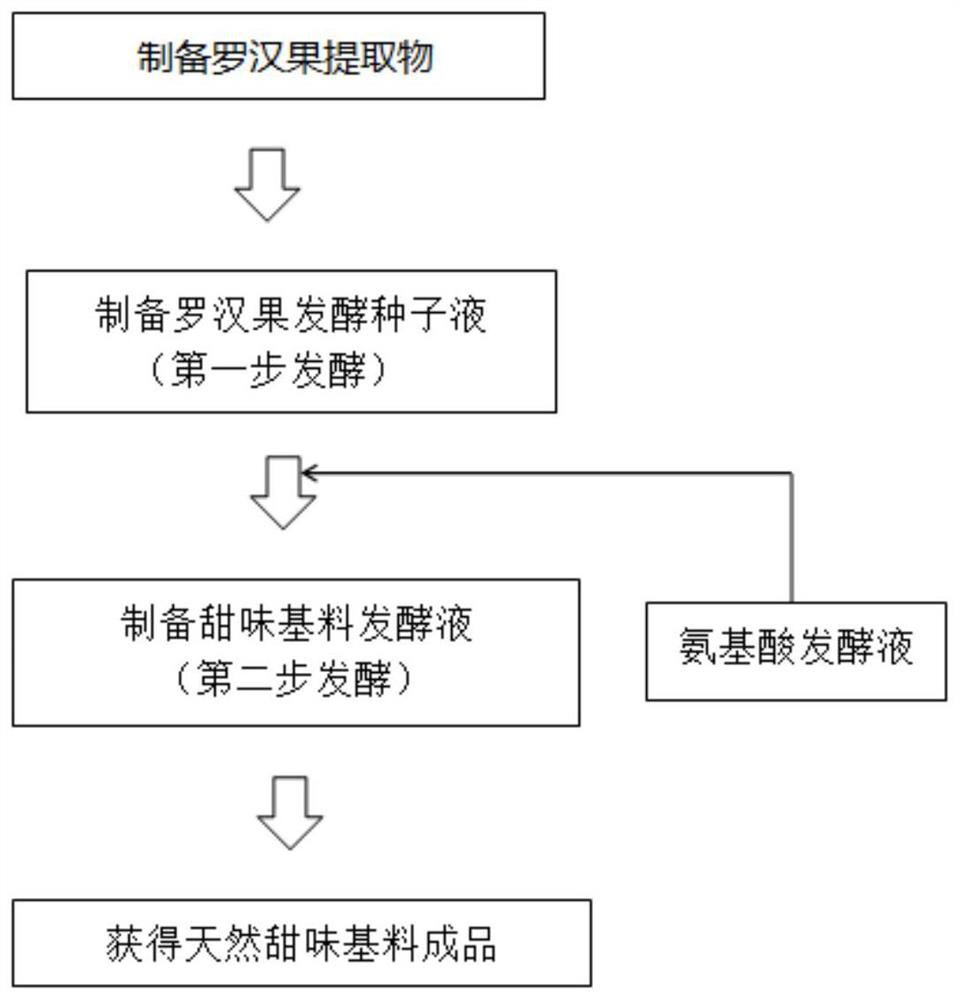

Method used

Image

Examples

Embodiment 1

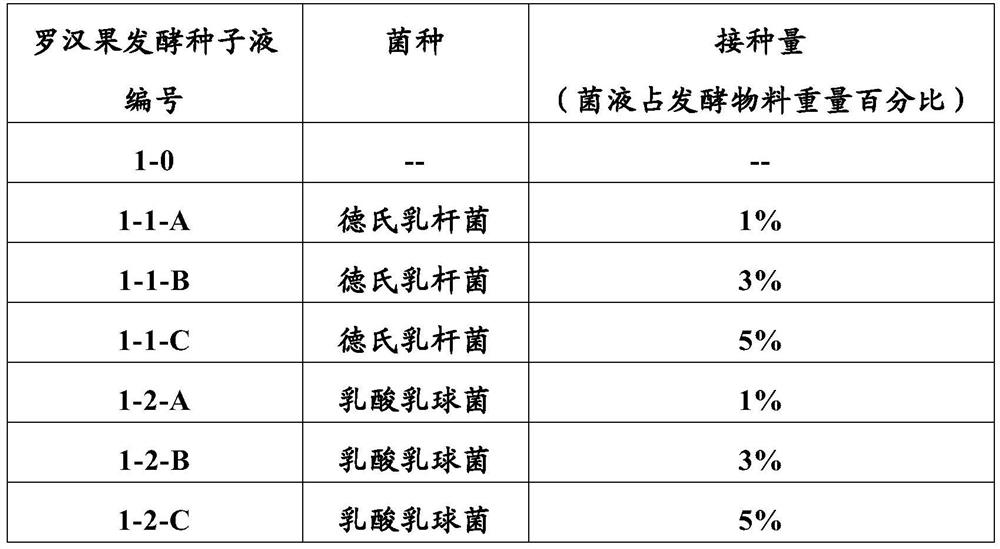

[0089] Embodiment 1 Preparation of Luo Han Guo fermented seed liquid

[0090] (1) Preparation of Luo Han Guo extract

[0091] The dried Luo Han Guo dried fruit is washed and dried naturally for use, and then pulverized, and the dried Luo Han Guo dried fruit powder obtained by the processing is passed through a 40-mesh sieve. Place 4kg of dried Luo Han Guo dried fruit powder in an extraction tank, then add 400kg of pure water to the extraction tank, stir and soak for 2 days. After soaking, the material in the extraction tank was heated up, and the material in the extraction tank was kept at 40°C for 30min constant temperature thermal leaching. That is to say, the number of hot dips is 2 times in total. The Baume degree of Luo Han Guo extract is 16°Bé.

[0092] In order to improve the efficiency of thermal extraction, Luo Han Guo can also be pretreated by freezing before crushing. The freezing temperature is -20°C, and the freezing time is 2h.

[0093] After the hot leach...

Embodiment 2

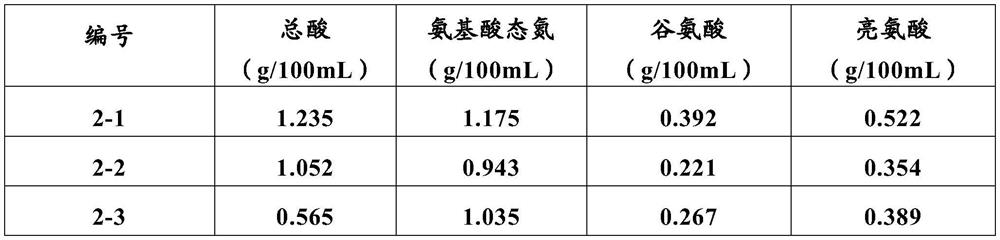

[0098] Example 2 Preparation of amino acid base liquid

[0099] (1) Preparation of No. 2-1 amino acid base solution (glutamic acid≥0.3g / 100mL, leucine≥0.4g / 100mL)

[0100] Using soybean and wheat flour as raw materials, the weight ratio of the two is 7:3, the soybean is removed impurities, soaked, filtered, then pressure-cooked and cooled, and the raw material of wheat flour is mixed to obtain the raw material for koji making. Aspergillus oryzae (product number: Shanghai Brewing 3.042) was gradually expanded and cultivated through inclined plane, triangular flask and curved plate to obtain seed koji. The seed koji with a weight ratio of 0.5% of the koji-making raw material is inoculated, and sent to a disc koji-making device for koji-making.

[0101] The koji material and water were mixed according to the weight ratio of 1:1.2, and after 40 ℃ of insulation fermentation for 10 hours, warm boiled water (48 ℃) of 0.8 times the weight of the koji material was added and mixed wi...

Embodiment 3

[0109] Example 3 Preparation of sweet base fermentation broth and detection of its lactic acid content and antioxidant activity

[0110] (1) Screening of fermentation conditions

[0111] The number 2-1 amino acid base liquid in Example 2 and the number 1-2-A Luo Han Guo fermented seed liquid in Example 1 were mixed uniformly according to different weight ratios, and the fermentation was carried out at different fermentation temperatures for different time periods to obtain the following 1 -5 groups of sweet base fermentation broth samples, and the results of the obtained sweet base are compared, and the results are shown in Table 3-1.

[0112] Table 3-1 Sample results of different treatment groups

[0113]

[0114] The detection of superoxide anion scavenging ability was carried out with a kit. Superoxide anion scavenging ability detection kit, product name: Solarbio; product number: BC1415, specification: 100T / 96S, and the assay operation can be performed according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com