SnTe Ge-doped thermoelectric material and preparation method thereof

A technology of thermoelectric material and discharge plasma, which is applied in the direction of lead wire material of thermoelectric device and the manufacture/processing of thermoelectric device. , low cost and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of preparation method of SnTe doped Ge thermoelectric material, concrete steps are as follows:

[0036] Step 1, the smelting of SnTe-doped Ge thermoelectric material, with the ratio of Sn powder, Ge powder and Te powder satisfying the amount of substance is 0.4:0.6:1, weigh 1.4259 g of Sn powder, 1.3086 g of Ge powder and 3.8318 g of Te powder After mixing, put the uniformly mixed raw material powder into the quartz tube to evacuate and seal the tube, then place the quartz tube vertically in the muffle furnace, with a heating time of 12 hours, a holding temperature of 1173 K, and a holding time of Melting for 6 hours, when the heat preservation is over, immediately take out the quartz tube and water quench to room temperature, and finally break the quartz tube to get the ingot;

[0037] Step 2, sintering the SnTe-doped Ge thermoelectric material, grinding the molten ingot obtained in step 1 with an agate mortar for 30 minutes and sieving to obtain a molten ingot ...

Embodiment 2

[0054] A method for preparing a SnTe-doped Ge thermoelectric material, the steps not specified in particular are the same as the preparation method in Example 1, the difference is that in the weighing process of step 1, the Sn powder, Ge powder and Te powder meet the amount of substances The ratio is 0.2:0.8:1, weigh 0.7130 g of Sn powder, 1.7449 g of Ge powder and 3.8318 g of Te powder and mix uniformly to obtain a SnTe-doped Ge thermoelectric material with high density. The obtained material is denoted as Ge 0.8 sn 0.2 Te.

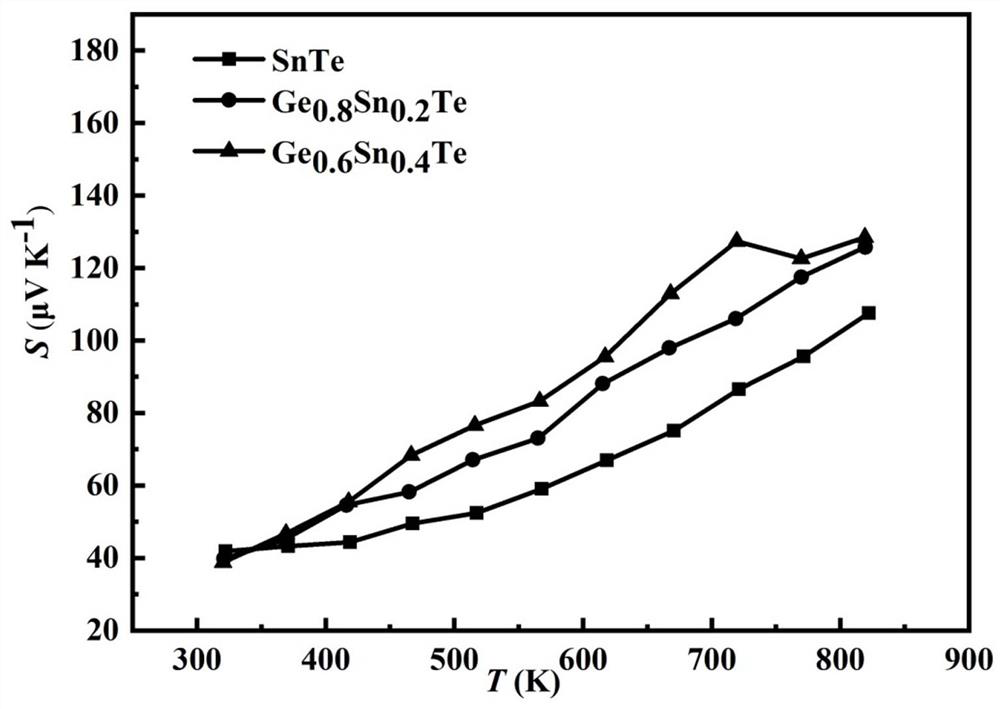

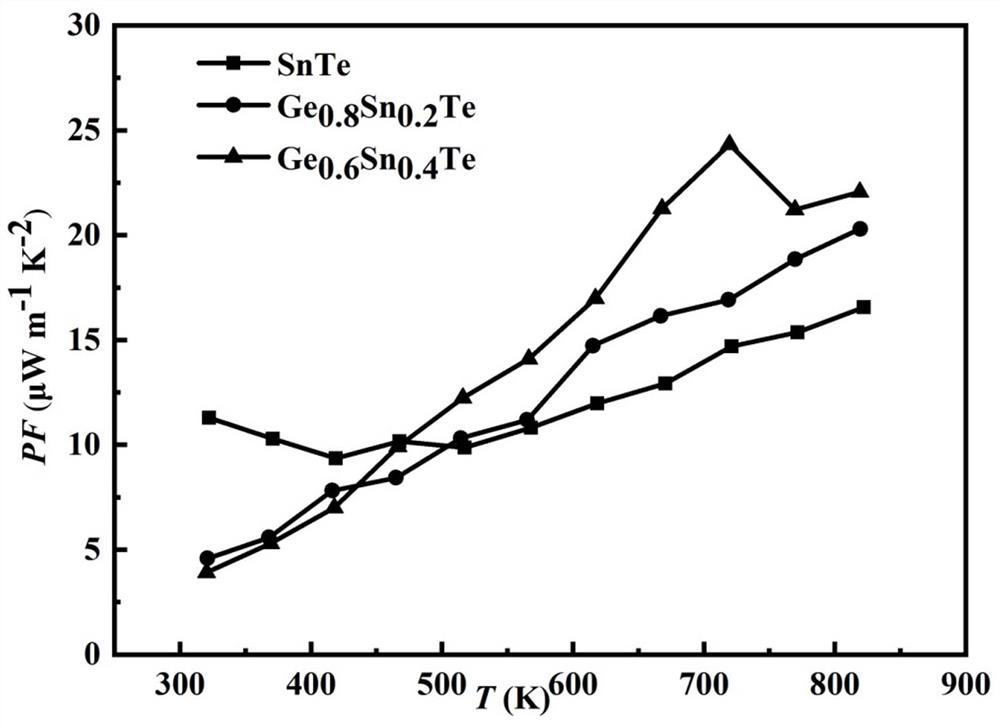

[0055] In order to prove that the obtained SnTe-doped Ge thermoelectric material is Ge 0.8 sn 0.2 Te, the obtained SnTe-doped Ge thermoelectric material is carried out structural feature test, and test method is identical with embodiment 1, and test result is as follows figure 2 shown. Through the analysis of the XRD pattern, it can be seen that the sample has diffraction peaks of different crystal planes and the diffraction intensity of the peak su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Seebeck coefficient | aaaaa | aaaaa |

| Power factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com