Non-polarized receiving electrode structure

A technology of receiving electrodes and electrodes, which is applied in the field of mine detection instruments, can solve problems such as inaccurate receiving potential signals, and achieve the effects of improving measurement accuracy, improving sealing performance, and facilitating disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

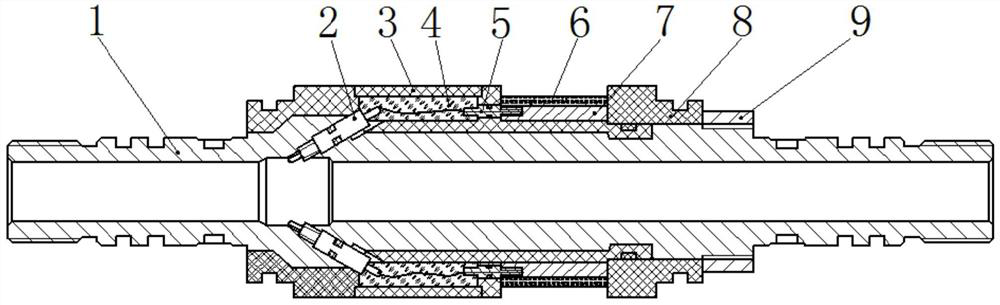

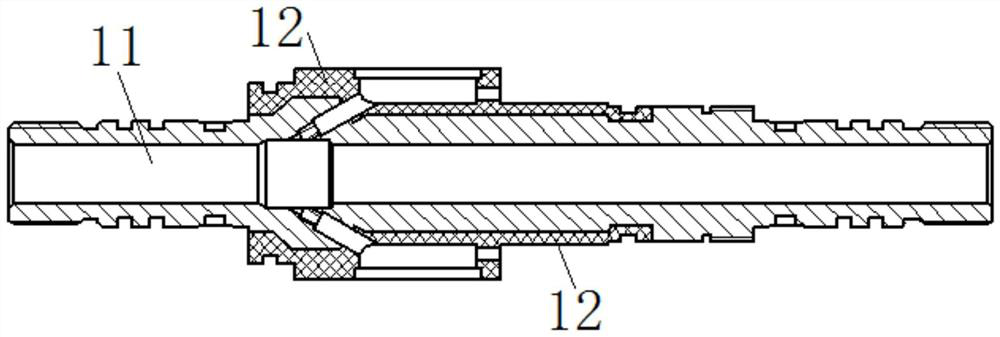

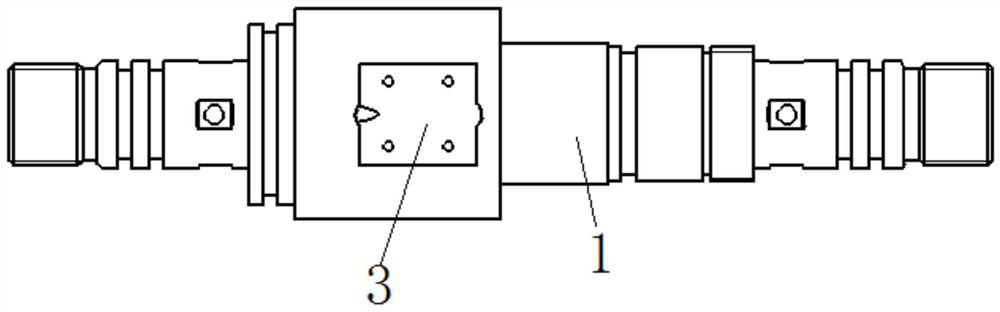

[0047] as attached Figure 1-8 As shown, this embodiment provides a non-polarized receiving electrode structure, including an electrode shaft 11, a glass fiber reinforced plastic layer 12, two pressure-bearing sealing plugs 2, two protective covers 3, silicone grease 4, two terminal posts 5, Receiving electrode 6, bushing 7, insulating sleeve 8 and support sleeve 9; FRP layer 12 is tightly sleeved on the outside of electrode shaft 11; FRP layer 12 is formed by winding FRP material on the surface of electrode shaft 11; both sides of the surface of FRP layer 12 The wire sealing grooves are symmetrically arranged respectively, and a bushing fixing position is arranged on one side of the wire sealing groove; the bushing 7 is fixedly sleeved in the bushing fixing position on the outside of the glass fiber reinforced plastic layer 12, and the receiving electrode 6 is fixedly threaded through the bushing 7 outside, and the receiving electrode 6 is a non-polarized electrode; in the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com