Solar energy, wind energy and fuel gas complementation combined hydrogen production and methane production circulating thermal power generation device

A technology of solar wind energy and thermal power generation, which is applied in the directions of solar thermal power generation, solar thermal storage, solar thermal energy, etc., to achieve the effects of improving the overall thermal cycle efficiency, increasing hours, and enhancing environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

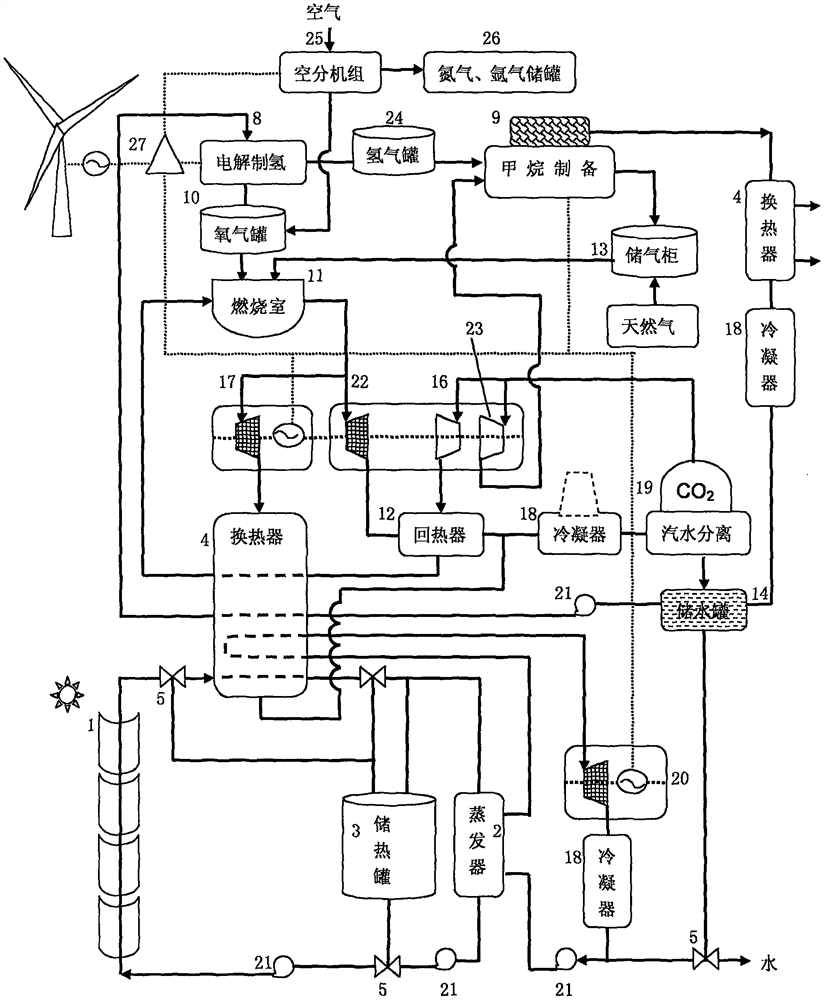

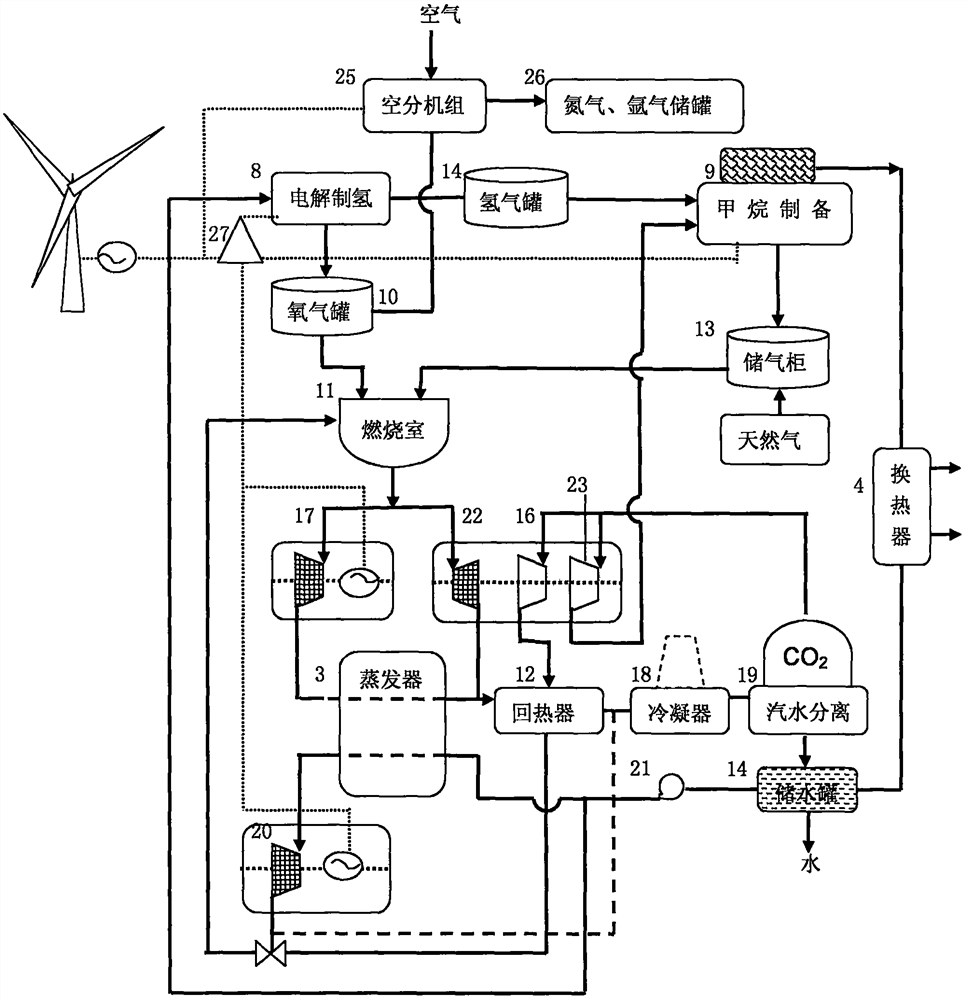

[0017] The outlet of the trough solar concentrator array 1 is connected to the inlet of the high-temperature heat exchanger 4 through the three-way valve 5, and at the same time connected to the inlet of the heat storage tank 3, and the corresponding outlet of the high-temperature heat exchanger 4 is connected to the inlet of the three-way valve 5, and the three-way valve 5 Two outlets are respectively connected to the inlet of the heat storage tank 3 and the inlet of the evaporator 2, and the outlet of the heat storage tank 3 is respectively connected to the inlet and outlet of two pressure pumps 21 through the three-way valve 5, wherein the outlet of the evaporator 2 is connected to the inlet of the pressure pump 21, and the outlet of the pressure pump 21 The outlet is connected to one end of the three-way valve 5 at the outlet of the heat storage tank 3, and the other end of the three-way valve 5 is connected to the inlet of the pressure pump 21, and the outlet of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com