EPS foam box and production formula thereof

A foam box and foam technology, applied in the field of EPS foam box and its production formula, can solve the problems of easy powder and debris, and achieve the effects of enhancing waterproof, improving performance and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

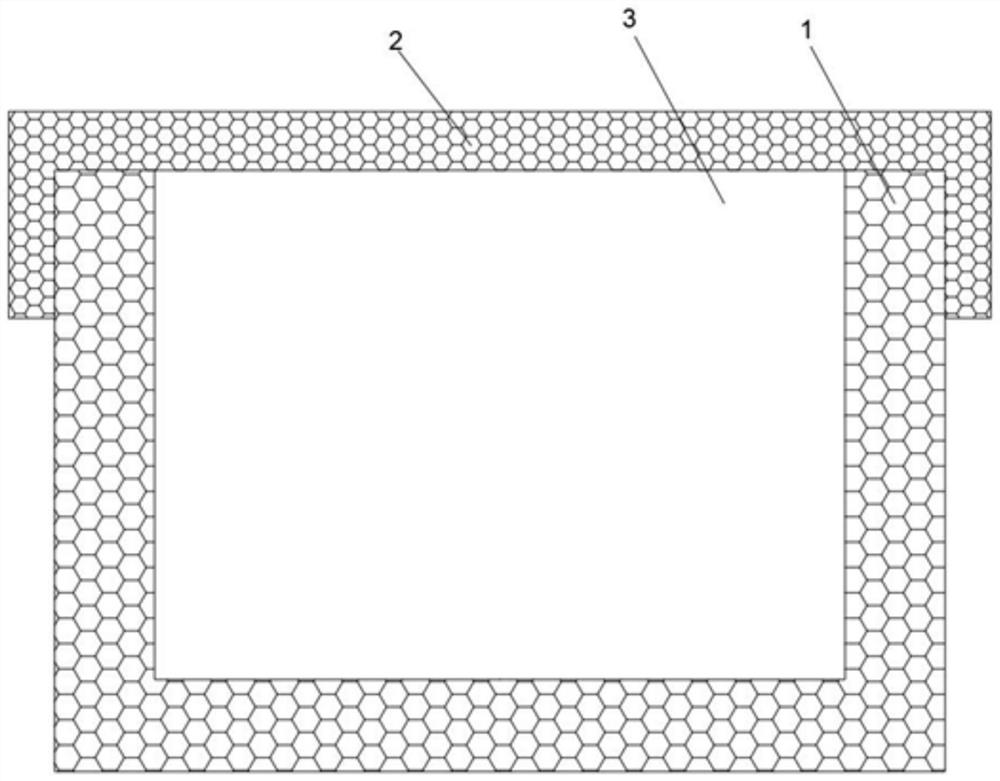

[0035]Such asfigure 1As shown: an EPS foam box including the foam box body 1, and the foam case body 1 is provided with a foam case cover 2; the foam box body 1 and the foam tank cover 2 are made of modified EPS foam; The foam tank cover 2 and the foam tank body 1 have a storage chamber 3.

[0036]The preparation method of modified EPS foam is included as follows:

[0037](1) Modified filler preparation:

[0038]1) The mica powder is irradiated, and the ball milling is performed after completion, and finally after 150 mesh sieves;

[0039]2) Calcination of serpentine, after the completion of the 700 mesh sieve, the serpentine is given;

[0040]3) The serpentine powder obtained from the mica powder and operation 2) will be mixed, and the powder is mixed;

[0041]4) The mixed powder obtained by operation 3) is inserted into the electrolytic cell, and then the electrolyte is added to the electrolytic cell, and the power supply is turned on, and after the completion of the centrifugation, cleaning, dryin...

Embodiment 2

[0056]Such asfigure 1As shown: an EPS foam box including the foam box body 1, and the foam case body 1 is provided with a foam case cover 2; the foam box body 1 and the foam tank cover 2 are made of modified EPS foam; The foam tank cover 2 and the foam tank body 1 have a storage chamber 3.

[0057]The preparation method of modified EPS foam is included as follows:

[0058](1) Modified filler preparation:

[0059]1) The mica powder is irradiated, and the ball milling is performed after completion, and finally after 150 mesh sieves;

[0060]2) Calcination of serpentine, after the completion of the 700 mesh sieve, the serpentine is given;

[0061]3) The serpentine powder obtained from the mica powder and operation 2) will be mixed, and the powder is mixed;

[0062]4) The mixed powder obtained by operation 3) is inserted into the electrolytic cell, and then the electrolyte is added to the electrolytic cell, and the power supply is turned on, and after the completion of the centrifugation, cleaning, dryin...

Embodiment 3

[0077]Such asfigure 1As shown: an EPS foam box including the foam box body 1, and the foam case body 1 is provided with a foam case cover 2; the foam box body 1 and the foam tank cover 2 are made of modified EPS foam; The foam tank cover 2 and the foam tank body 1 have a storage chamber 3.

[0078]The preparation method of modified EPS foam is included as follows:

[0079](1) Modified filler preparation:

[0080]1) The mica powder is irradiated, and the ball milling is performed after completion, and finally after 150 mesh sieves;

[0081]2) Calcination of serpentine, after the completion of the 700 mesh sieve, the serpentine is given;

[0082]3) The serpentine powder obtained from the mica powder and operation 2) will be mixed, and the powder is mixed;

[0083]4) The mixed powder obtained by operation 3) is inserted into the electrolytic cell, and then the electrolyte is added to the electrolytic cell, and the power supply is turned on, and after the completion of the centrifugation, cleaning, dryin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com