Soft, light and ultra-warm airgel filling material for shoes, clothes and quilts and manufacturing method thereof

A filling material and airgel technology, applied in the direction of non-woven fabrics, textiles and papermaking, etc., can solve the problems of impermeability to washing, poor air permeability, poor moisture conductivity, etc., and achieve good air permeability, moisture conductivity, and good dimensional stability and warmth retention, improved stability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

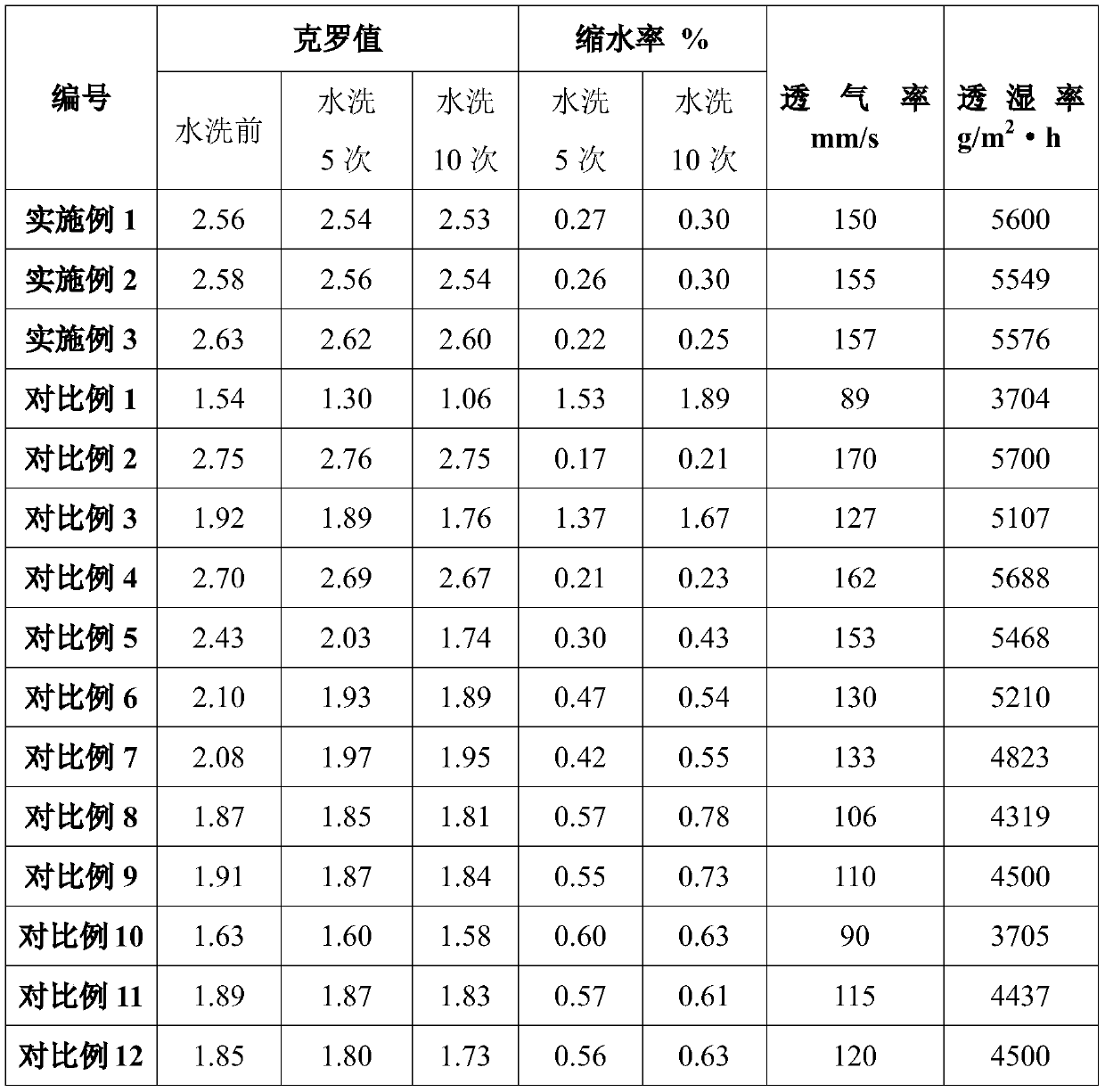

Examples

Embodiment 1

[0112] Embodiment 1 provides a kind of soft and light ultra-warm airgel filling material for shoes, clothing and bedding, and the filling material is made of non-woven fabric and glue solution through processing.

[0113] The raw materials of the non-woven fabric include special-shaped fibers and round fibers, which were respectively purchased from Zhejiang Jinxia New Material Technology Co., Ltd. and Haiyan Tianma Chemical Fiber Co., Ltd.;

[0114] The mass ratio of the special-shaped fiber to the round fiber is 1:8.

[0115] The raw material of described glue comprises following components by weight: SiO 2 4 parts of airgel, 50 parts of adhesive, 4.2 parts of dispersant (4 parts of sodium polyacrylate, 0.2 parts of maleic acid-acrylic acid copolymer), 200 parts of organic solvent.

[0116] The SiO 2 The airgel has a pore size of 20-30 nm and was purchased from Jiangxi Bozhikai Technology Co., Ltd.

[0117] Described binding agent is the polyether type polyurethane dispers...

Embodiment 2

[0133] Embodiment 2 provides a soft, light and thin ultra-warm airgel filling material for shoes, clothing and bedding. The filling material is processed and manufactured from non-woven fabric, glue, and coagulation bath.

[0134] The raw materials of the non-woven fabric include special-shaped fibers and round fibers, which were respectively purchased from Zhejiang Jinxia New Material Technology Co., Ltd. and Haiyan Tianma Chemical Fiber Co., Ltd.;

[0135] The mass ratio of the special-shaped fiber to the round fiber is 1:2.

[0136] The raw material of described glue comprises following components by weight: SiO 2 8 parts of airgel, 70 parts of adhesive, 21.2 parts of dispersant (20 parts of sodium polyacrylate, 1.2 parts of maleic acid-acrylic acid copolymer), 300 parts of organic solvent.

[0137] The SiO 2 The airgel has a pore size of 20-30 nm and was purchased from Jiangxi Bozhikai Technology Co., Ltd.

[0138] The adhesive is an epoxy group-containing polyether pol...

Embodiment 3

[0147] Embodiment 3 provides a soft, light and thin ultra-warm airgel filling material for shoes, clothing and bedding. The filling material is processed and manufactured from non-woven fabric, glue solution and coagulation bath.

[0148] The raw materials of the non-woven fabric include special-shaped fibers and round fibers, which were respectively purchased from Zhejiang Jinxia New Material Technology Co., Ltd. and Haiyan Tianma Chemical Fiber Co., Ltd.;

[0149] The mass ratio of the special-shaped fiber to the round fiber is 1:4.

[0150] The raw material of described glue comprises following components by weight: SiO 2 6 parts of airgel, 60 parts of adhesive, 12.6 parts of dispersant (12 parts of sodium polyacrylate, 0.6 parts of maleic acid-acrylic acid copolymer), 250 parts of organic solvent.

[0151] The SiO 2 The airgel has a pore size of 20-30 nm and was purchased from Jiangxi Bozhikai Technology Co., Ltd.

[0152] The adhesive is an epoxy group-containing polye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com