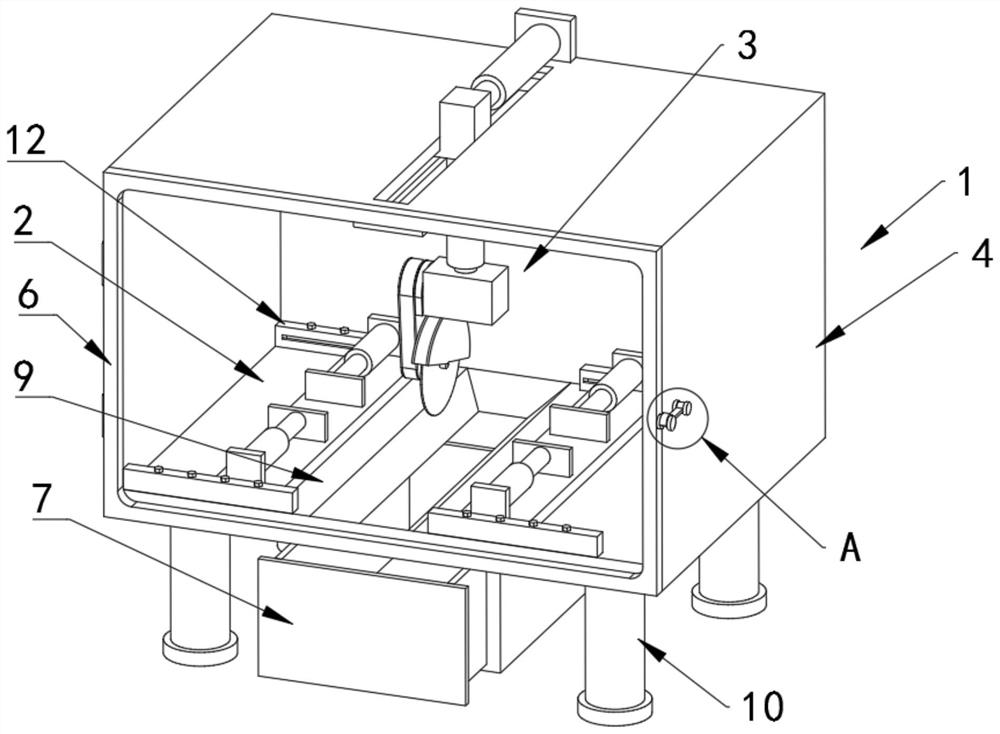

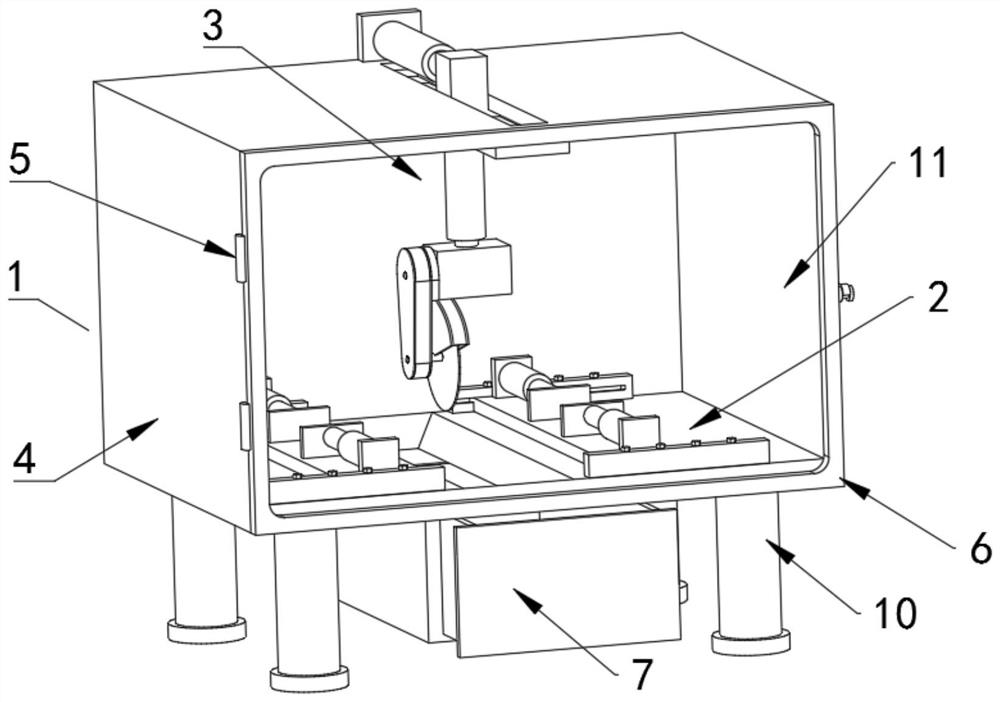

Environment-friendly building material cutting equipment

A technology of cutting equipment and equipment, which is applied in the direction of sounding equipment, dust removal, instruments, etc., can solve problems such as environmental pollution, debris inconvenience, and hearing loss of staff, and achieve the effect of facilitating collection and processing and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

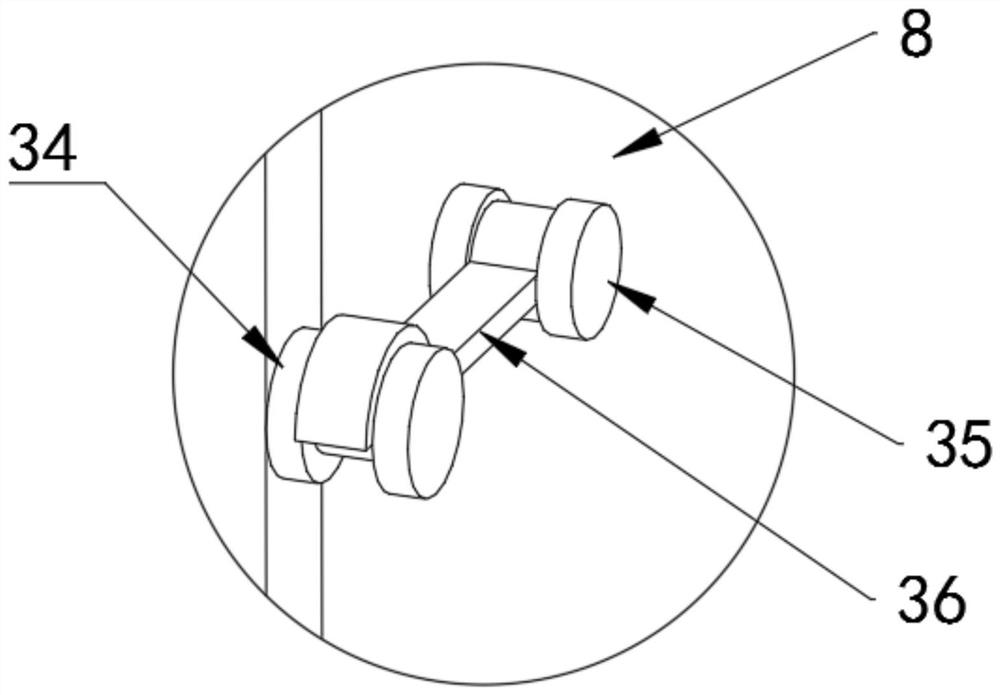

[0029] As an embodiment of the present invention, the hasp 8 includes a first fixed shaft 34, a second fixed shaft 35 and a bayonet 36, the first fixed shaft 34 is fixedly connected to the side wall of the observation door 6, and the second The two fixed shafts 35 are fixedly connected to the side wall of the equipment chamber 4 , and the bayonet 36 is connected to the second fixed shaft 35 in rotation. When carrying out the cutting work, the bayonet 36 is carried on the first fixed shaft 34 along the second fixed shaft 35, so as to prevent the observation door 6 from opening during the working process, and the noise and debris dust generated during the work are isolated, and the sealing work is achieved. Effect.

[0030] As an embodiment of the present invention, the lower sliding groove 12 is provided with holes for bolts 33 , the working plate 13 is provided with holes for bolts 33 , and the holes for bolts 33 and the bolts 33 are connected by bolts 33 . When cutting build...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com