High-precision grinding numerical control grinding machine

A CNC grinding machine, high-precision technology, applied in the direction of grinding bed, grinding machine parts, grinding machines, etc., can solve the problem that the lifting precision of the grinding table cannot be adjusted, and achieve the effect of improving precision and grinding precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

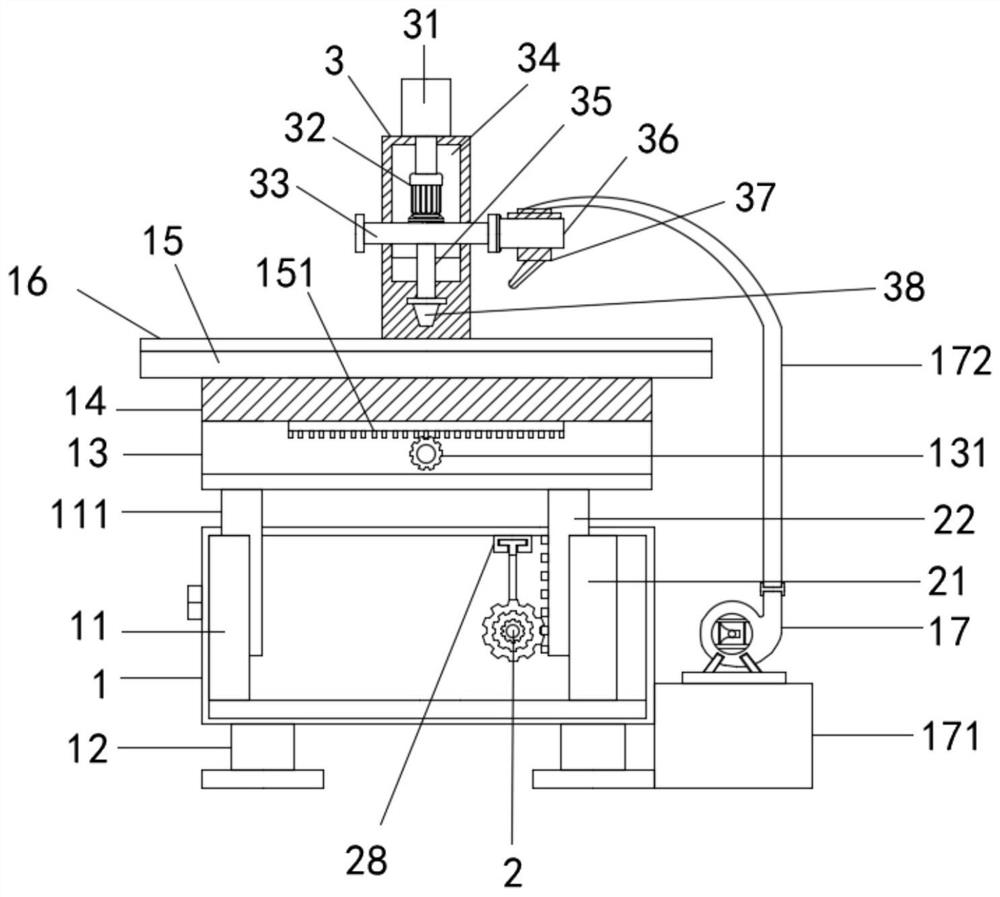

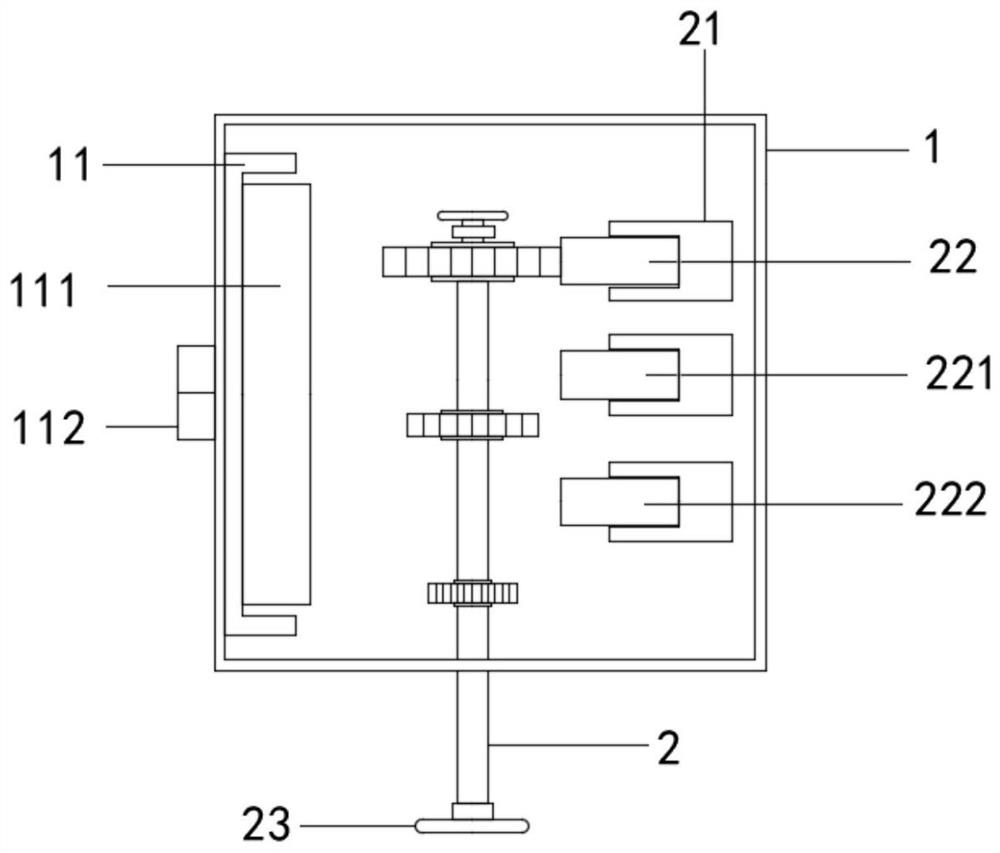

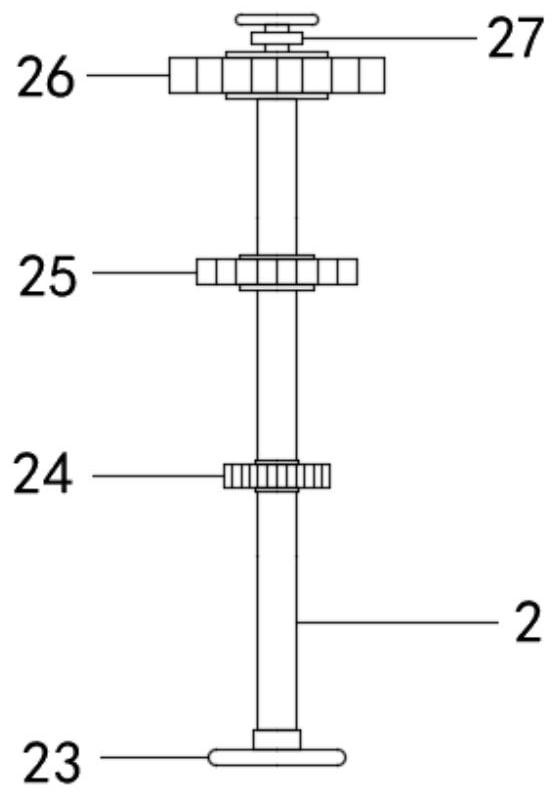

[0030] Refer to attached Figure 1-Figure 7 , a CNC grinding machine for high-precision grinding in this embodiment, including a gearbox 1, a shift lever 2 and a support arm 3;

[0031] Further, the inner wall of the gearbox 1 is fixed with a positioning seat 2 21, and the inner wall of the left end of the positioning seat 21 is inserted into the high-speed gear ejector 22, the medium-speed gear ejector 221 and the low-speed gear ejector 222, and the gearbox 1 The inner wall is plugged with the shift lever 2, and the outer wall of the shift lever 2 is fixedly installed with a small gear 24, a middle gear 25 and a large gear 26, and the large gear 26 is connected to the high-speed gear push rod 22, and the outer wall of the shift lever 2 is covered Connect the draw ring 27, the top seat 28 is fixedly installed on the inner wall of the gearbox 1, the inner wall of the top seat 28 is provided with a chute two 281, and the inner wall of the two chute 281 is inserted with a pull bl...

Embodiment 2

[0043] Refer to attached Figure 8 , a CNC grinding machine for high-precision grinding in this embodiment, including a gearbox 1, a shift lever 2 and a support arm 3;

[0044] Further, the lower end of the gearbox 1 is fixedly equipped with a shock absorber rod 19, and the lower end of the shock absorber rod 19 is fixedly installed with a support foot 191. The shock absorber rod 19 has the effect of damping the gearbox 1, preventing the gearbox 1 from vibrating and damaging the article. The grinding accuracy is high, and the supporting foot 191 has the function of supporting the gearbox 1.

[0045] The use process of the present invention is as follows: when using the present invention, the positioning seat 2 21 is fixedly installed on the inner wall of the gearbox 1, and the inner wall of the left end of the positioning seat 2 21 is inserted into the high-speed gear push rod 22, the medium-speed gear push rod 221 and the low-speed gear push rod 222 , the gear lever 2 is plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com