Compressor cooling machine for oil refining and chemical engineering

A technology for oil refining, chemical industry, and compressors, which is applied in the direction of furnace cooling, crucible furnace, furnace, etc., and can solve the problems of hidden dangers of compressed oil liquid tube bursting, interference with thermal expansion and conduction of oil refining, and easy gyration of control deviations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

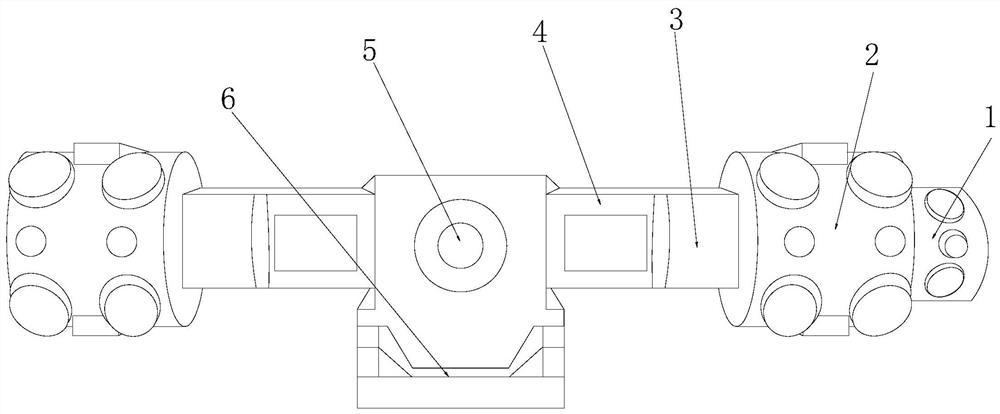

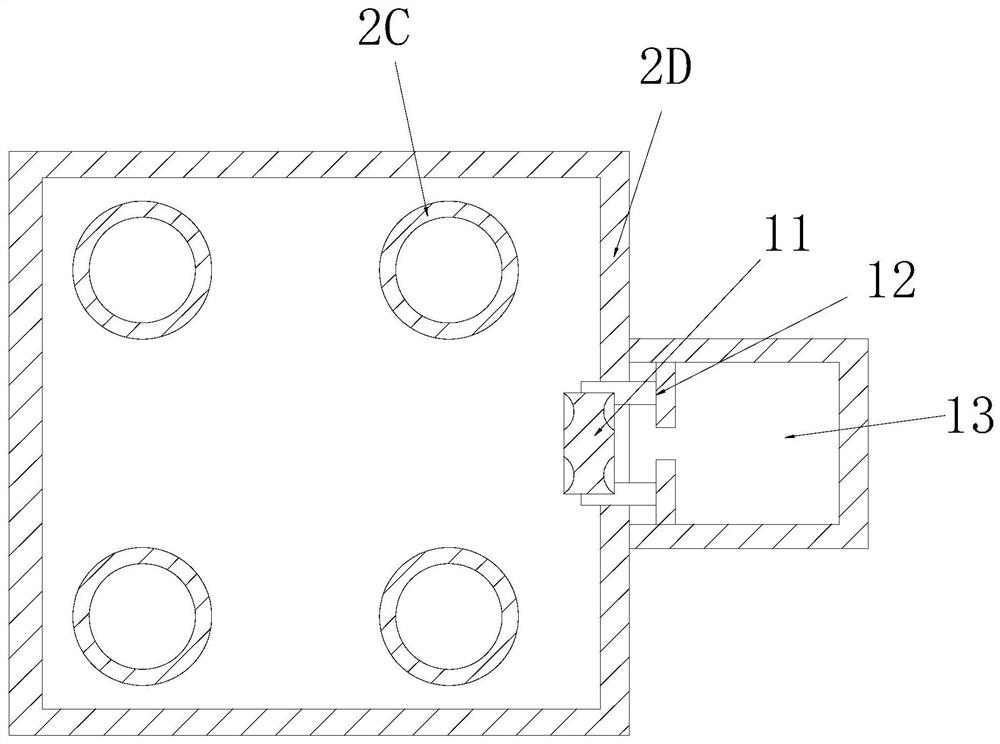

[0035] see Figure 1-Figure 8 , the present invention provides a compressor cooler for oil refining and chemical industry, its structure includes: sleeve groove 1, cooling compression drum 2, deflector column plate groove 3, frame groove body 4, rotating shaft disk 5, box seat groove 6, The cooling compression drum 2 is nested on the left side of the sleeve groove 1 and the axes are collinear. The cooling compression drum 2 is fastened together with the deflector column plate groove 3, and the deflector column plate groove 3 It is integrated with the frame tank 4 and is on the same vertical plane. The rotating shaft disk 5 is installed on the top of the box seat groove 6 and is perpendicular to each other. There are two frame tanks 4 and they are respectively inserted in On the left and right sides of the rotating shaft disk 5, the cooling compression drum 2 is provided with a bladder backing plate shaft frame 2A, a condensation pipe folding groove 2B, a through-hole ring fram...

Embodiment 2

[0043] see Figure 1-Figure 8 , the present invention provides a compressor cooler for refining and chemical industry, other aspects are the same as in Embodiment 1, the difference is:

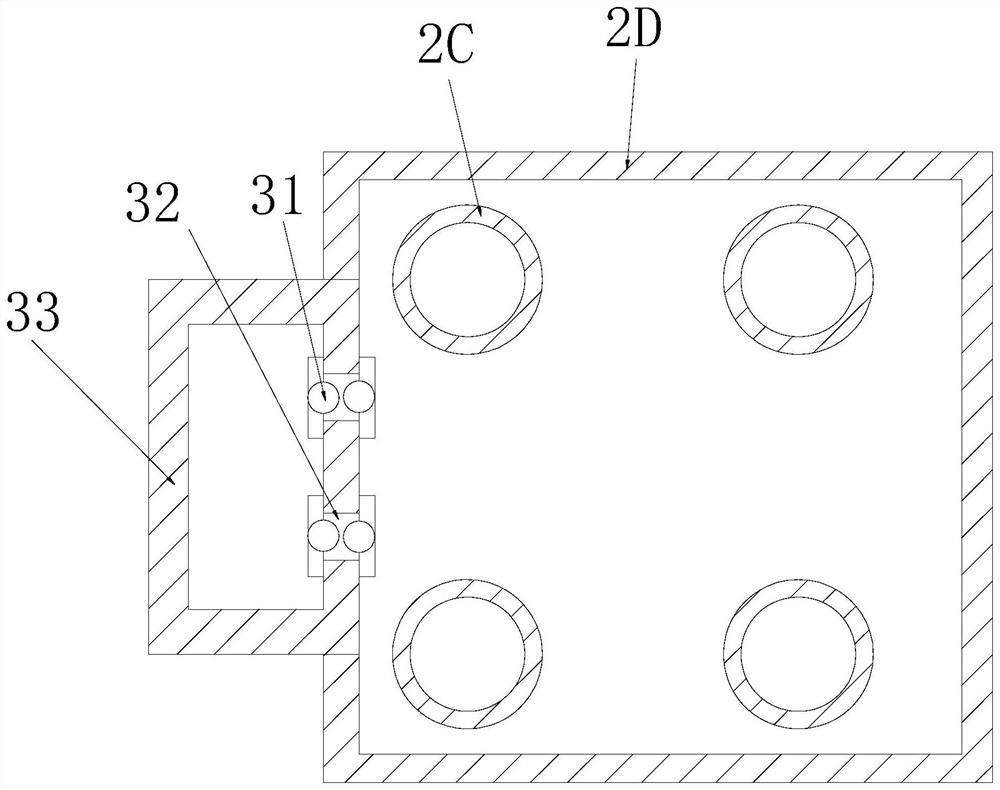

[0044] see image 3 , the guide column plate groove 3 is composed of a button wheel 31, an I-shaped fastener 32, and a column plate shell groove 33. The button wheel 31 and the I-shaped fastener 32 are fastened together and are on the same vertical plane, The I-shaped fastener 32 is installed on the right side of the column plate shell groove 33 , and the I-shaped fastener 32 is fastened to the column plate shell groove 33 to form the locking operation effect of the shell.

[0045] see Figure 6 , the button wheel 31 is made up of the fan plate shaft wheel groove 311, the arc lobe plate 312, and the arc rail bar 313. The fan plate shaft wheel groove 311 and the arc lobe plate 312 adopt clearance fit, and the arc lobe plate 312 and the arc lobe plate The rail rods 313 are nested together and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com