Tunnel construction dust monitoring and automatic water spraying system

A technology of tunnel construction and water spraying system, which is applied in dust prevention, measuring devices, fire prevention, etc. It can solve the problems of environmental pollution, inability to flexibly solve tunnel dust reduction at the same time, and endanger the health of tunnel construction personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0024] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

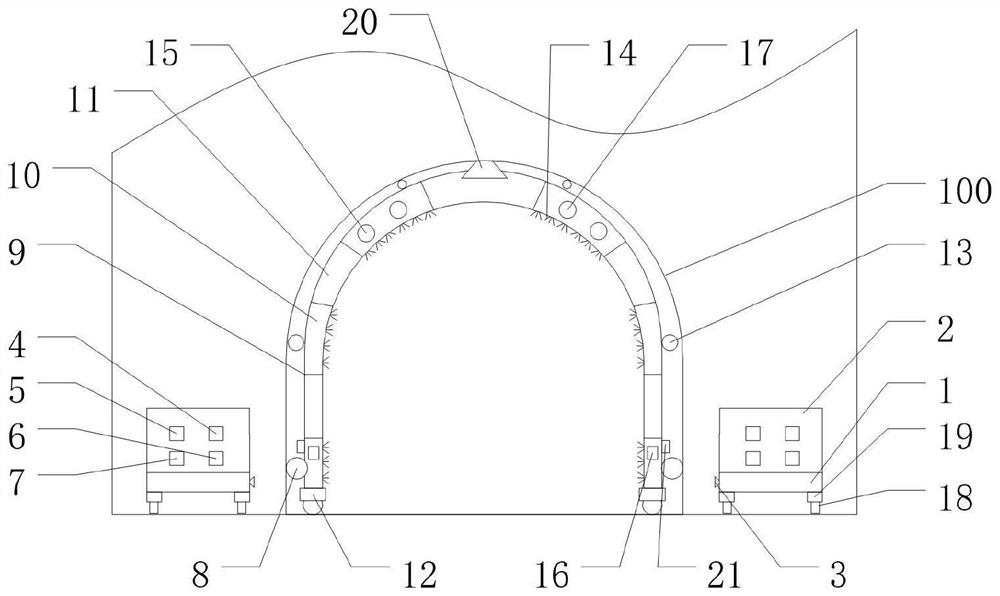

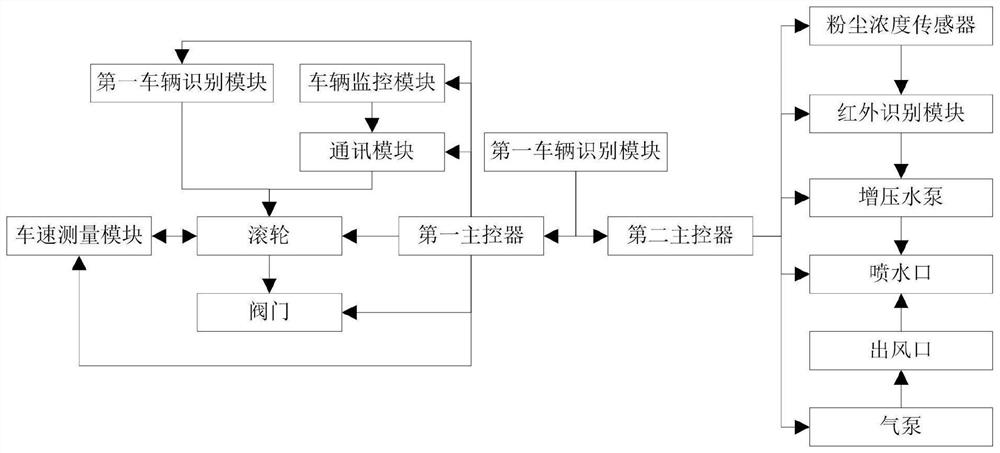

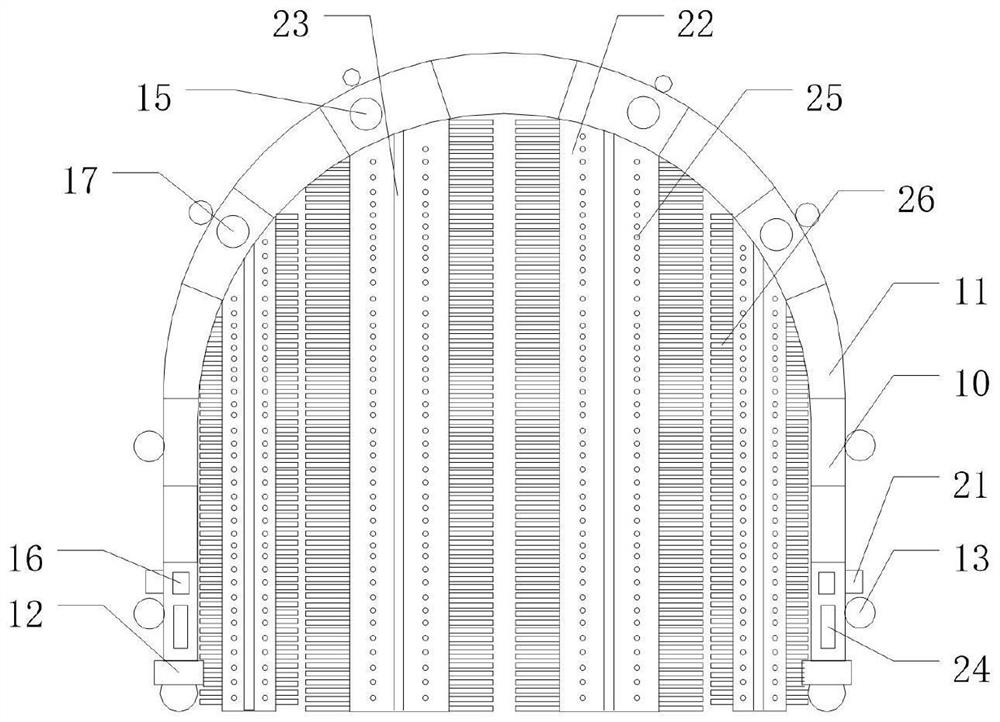

[0025] Such as Figure 1-3 As shown, the present invention provides a tunnel construction dust monitoring and automatic water spraying system, including:

[0026]The dust suppression mechanism outside the tunnel, which includes a pair of dust suppression trolleys symmetrically arranged on both sides of the opening of the tunnel to be constructed 100 and a vehicle monitoring module arranged at the farthest distance from the preset dust suppression trolley to the opening of the tunnel to be constructed 100 The dust suppression trolley includes a support 1, a water tank 2, a spray no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com