Dust-falling wheel pick press-planing type combined mining machine for strip mine

A technology of open-pit mines and combined mining machines, which is applied in the fields of open-pit mine mining, cutting machinery, and discharge machinery, and can solve problems such as weak adaptability, no engineering examples, and affecting the health of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

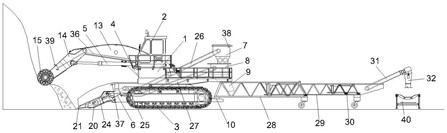

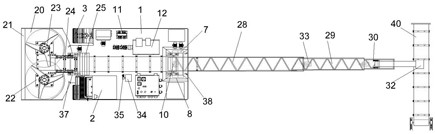

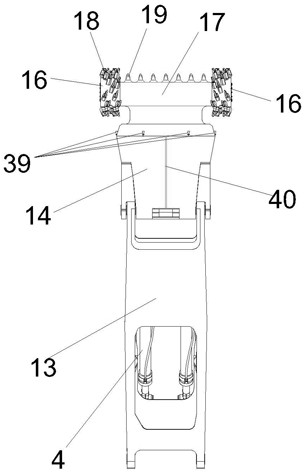

[0025] As shown in the accompanying drawings, the dust-suppressing wheel, pick and planer combined mining machine of this open-pit mine includes a host platform 1, which is rectangular, adopts a rectangular truss structure, and is welded by high-strength profiles as the main material.

[0026] The upper part of the host platform 1 is provided with a driver's cab 2, and the directly purchased integral driver's cab 2 is the operation control center of the whole machine. All control systems are installed in the driver's cab 2, and there are two modes of operation, remote control and manual. The control system is already a standard configuration of mechanical equipment at this stage, and it is a basic configuration, so there is no need to repeat it.

[0027] The lower part of the host platform 1 is provided with a walking crawler 3, which is also a directly purchased molded product. The walking crawler 3 includes a traveling motor, a traveling reducer, a driving wheel, a crawler fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com