Bio-based environment-friendly trace lubricant and preparation method thereof

A micro-lubricant, bio-based technology, applied in the field of lubrication, can solve the problems of unfriendly sulfur and chlorine-containing additives, pollution, large amount of lubricant usage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 1000g of konjac polysaccharide and 1200g of myristic acid into the reaction kettle, add 3g of phosphotungstic acid as a catalyst, and react at a temperature of 220°C for 3 hours under the protection of nitrogen; during the reaction process, decompress and remove water; that is, a A lubricant composition.

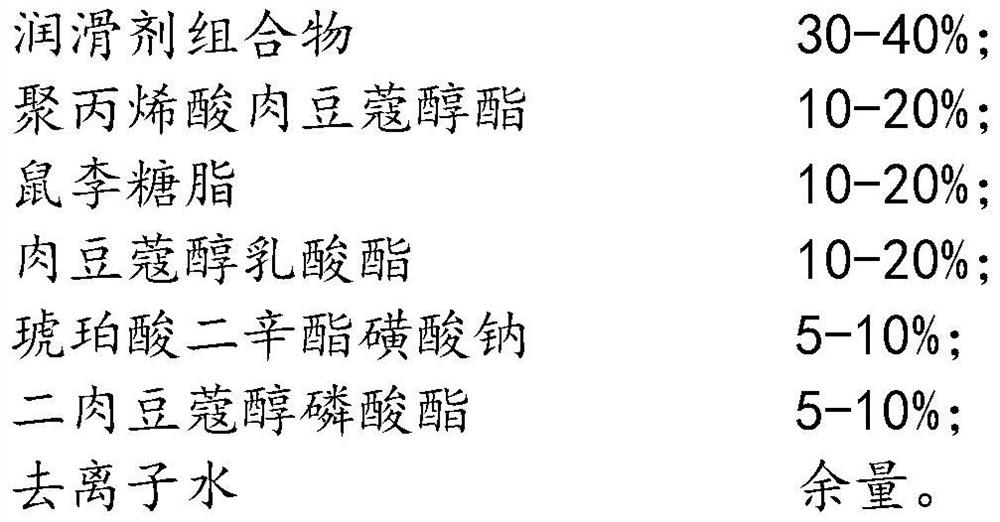

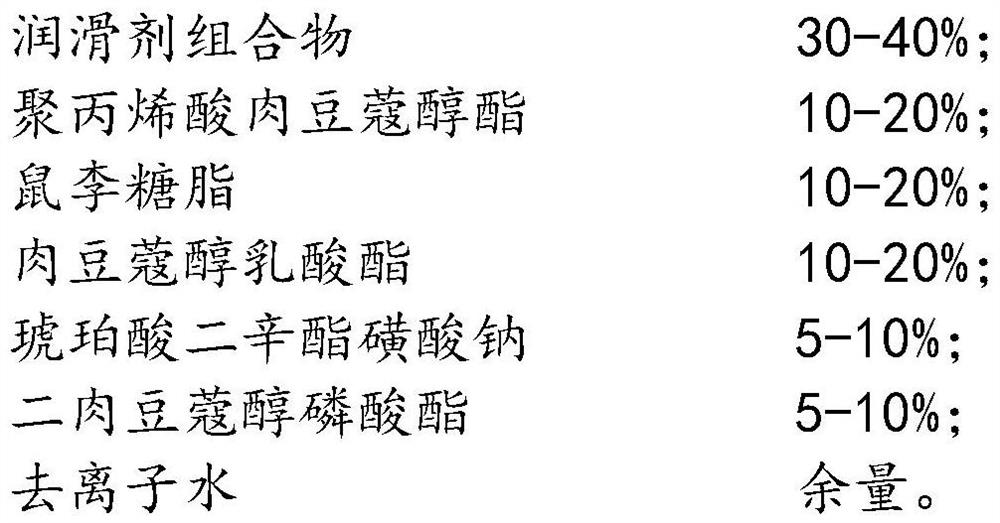

[0037] Weigh 400g of lubricant composition, 100g of myristyl polyacrylate, 200g of rhamnolipid, 100g of myristyl lactate, 50g of dioctyl sodium sulfosuccinate, 50g of dimyristyl phosphate, deionized Mix and stir 100g of water at room temperature until it becomes transparent, which is a kind of bio-based environmental protection micro-lubricant.

[0038] The preparation method of above-mentioned myristyl polyacrylate:

[0039] Step 1: Weigh 72.06g (1mol) of acrylic acid, 214.39g (1mol) of myristyl alcohol, and 2g (concentration: 50%) of sulfuric acid catalyst into the reaction kettle, and react at a reaction temperature of 180°C for 5 hours; after the reaction, ...

Embodiment 2

[0042] Weigh 1000g of konjac polysaccharide and 1000g of myristic acid into the reaction kettle, add 20g of catalyst phosphoric acid, and react at a temperature of 180°C for 5 hours under the protection of nitrogen; during the reaction process, decompress and remove moisture; it is a kind of lubrication agent composition.

[0043] Weigh 300g of lubricant composition, 200g of myristyl polyacrylate, 100g of rhamnolipid, 200g of myristyl lactate, 80g of dioctyl sodium sulfosuccinate, 70g of dimyristyl phosphate, deionized Mix and stir 50g of water at room temperature until it becomes transparent, which is a kind of bio-based environmental protection micro-lubricant.

[0044] The preparation method of above-mentioned myristyl polyacrylate:

[0045] Step 1: Weigh 72.06g (1mol) of acrylic acid, 257.27g (1.2mol) of myristyl alcohol, and 7g of phosphoric acid into the reaction kettle, and react at a reaction temperature of 220°C for 4 hours; after the reaction, depressurize and disch...

Embodiment 3

[0048] Weigh 1000g of konjac polysaccharide and 1100g of myristic acid into the reaction kettle, add 11g of catalyst phosphoric acid, and react at a temperature of 200°C for 4 hours under the protection of nitrogen; during the reaction process, decompress and remove moisture; it is a kind of lubrication agent composition.

[0049] Weigh 350g of lubricant composition, 150g of myristyl polyacrylate, 150g of rhamnolipid, 150g of myristyl lactate, 60g of dioctyl sodium sulfosuccinate, 60g of dimyristyl phosphate, deionized Mix and stir 80g of water at room temperature until it becomes transparent, which is a kind of bio-based environmental protection micro-lubricant.

[0050] The preparation method of above-mentioned myristyl polyacrylate:

[0051] Step 1: Weigh 72.06g (1mol) of acrylic acid, 235.83g (1.1mol) of myristyl alcohol, and 4g of phosphoric acid into the reaction kettle, and react at a reaction temperature of 200°C for 4.5 hours; after the reaction, depressurize and disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com