Heat storage material for process for preparing propylene by propane dehydrogenation and preparation method of heat storage material

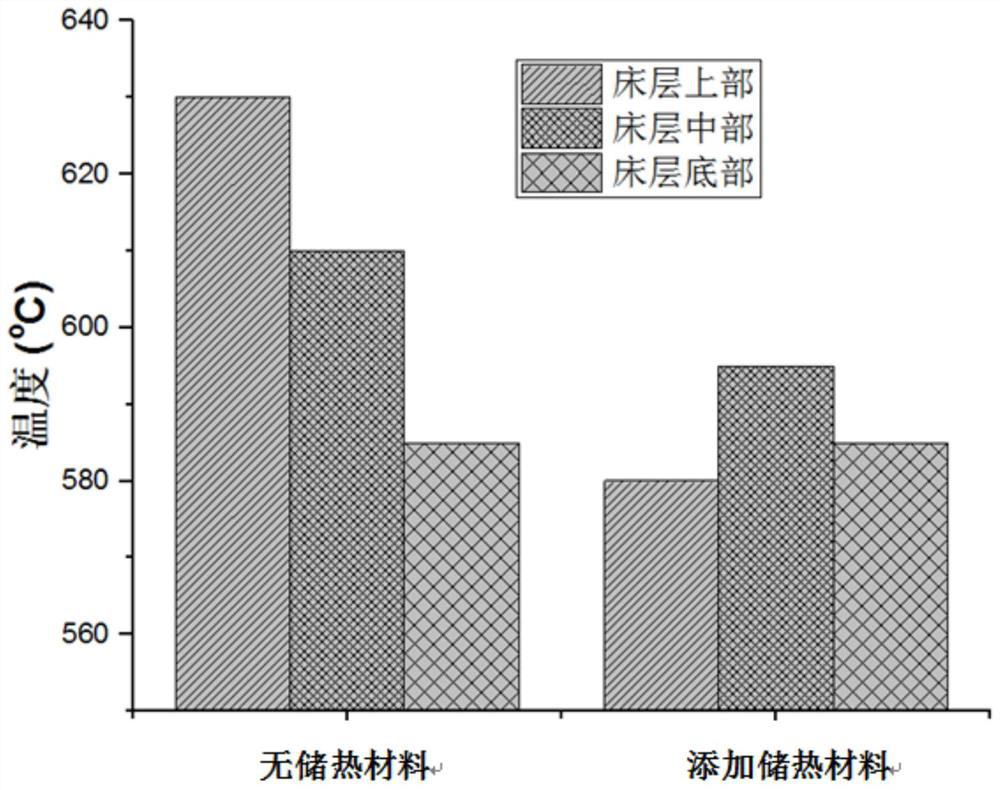

A technology for heat storage materials and propane, applied in the direction of heat exchange materials, chemical instruments and methods, hydrocarbons, etc. The reduction can not be very uniform and other problems, to achieve the effect of low cost, reduce device energy consumption, and improve selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

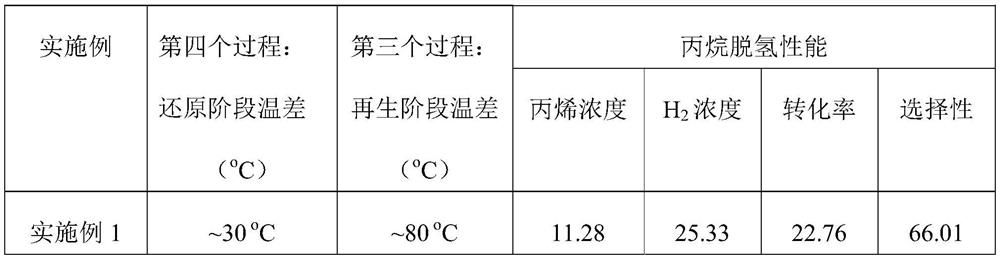

Embodiment 1

[0020] Preparation of 20wt% CuO / SiO by Impregnation 2 Heat storage material, weigh a certain amount of copper nitrate according to the chemical formula, dissolve it in deionized water, stir it for 25 minutes, and add it to the columnar SiO 2 In the carrier, the solution was evaporated to dryness at 80°C with stirring, and the obtained material was dried overnight in an oven at 100°C. After drying, the heat storage material was calcined in a muffle furnace at 600° C. for 3 hours.

Embodiment 2

[0022] Preparation of 10wt% CuO / SiO by impregnation method 2 Heat storage material, weigh a certain amount of copper nitrate according to the chemical formula, dissolve it in deionized water, stir it for 25 minutes, and add it to the columnar SiO 2 In the carrier, the solution was evaporated to dryness at 80°C with stirring, and the obtained material was dried overnight in an oven at 100°C. After drying, the heat storage material was calcined in a muffle furnace at 1000° C. for 3 hours.

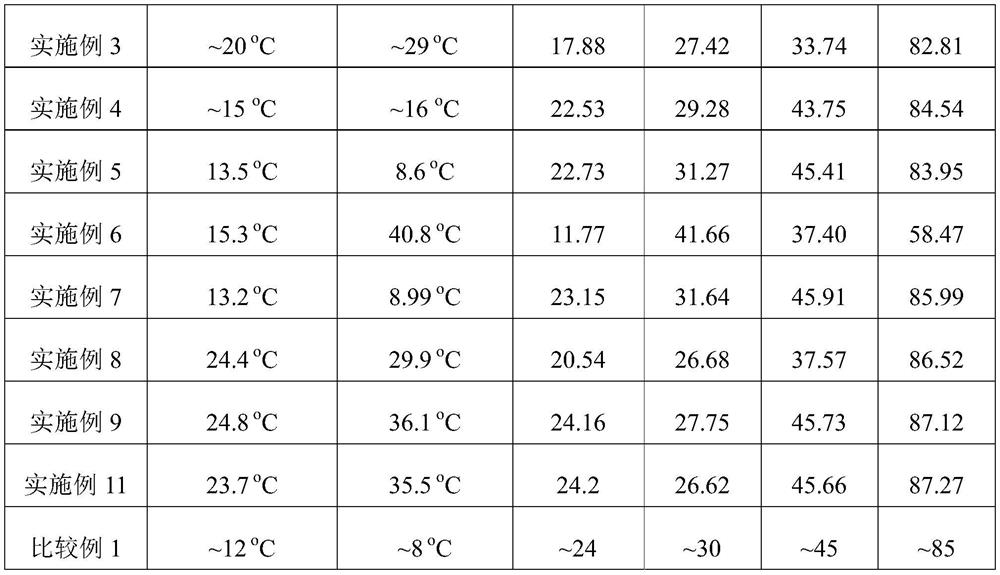

Embodiment 3

[0024] Preparation of 10wt% Co by impregnation 3 o 4 / Al 2 o 3 Heat storage material, according to the chemical formula, take a certain amount of cobalt nitrate and dissolve it in deionized water, stir it for 25 minutes, then add it to the columnar Al 2 o 3 In the carrier, the solution was evaporated to dryness at 80°C with stirring, and the obtained material was dried overnight in an oven at 100°C. After drying, the heat storage material was calcined in a muffle furnace at 1000° C. for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com