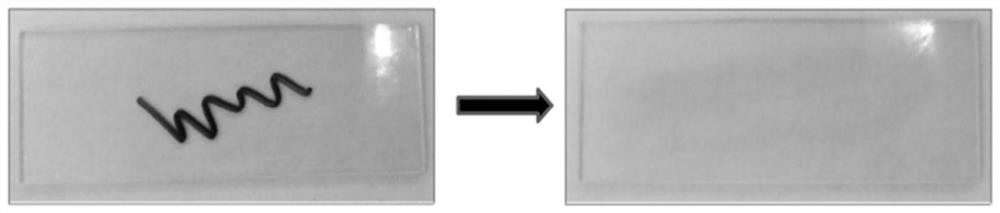

Photocuring anti-doodling coating with self-healing function and preparation method and application thereof

A light-curing and anti-graffiti technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced surface anti-graffiti, easy loss of surface efficacy, and difficulty in large-scale construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

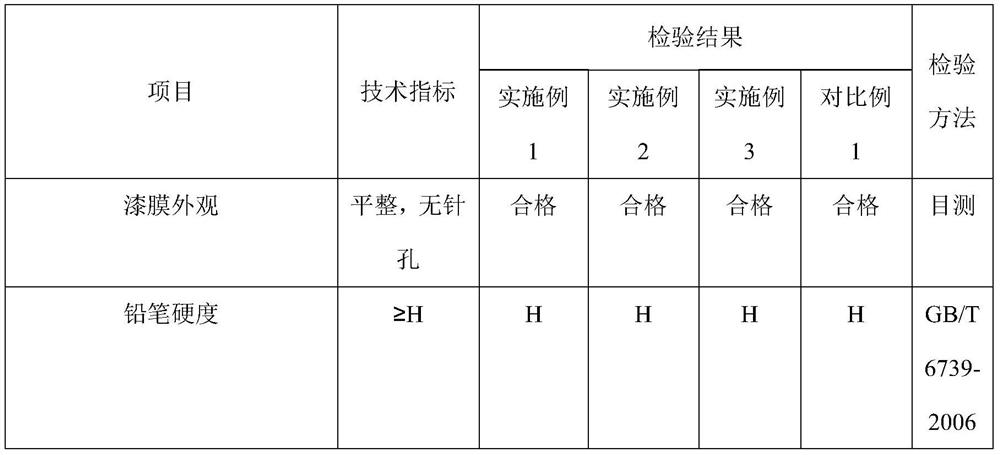

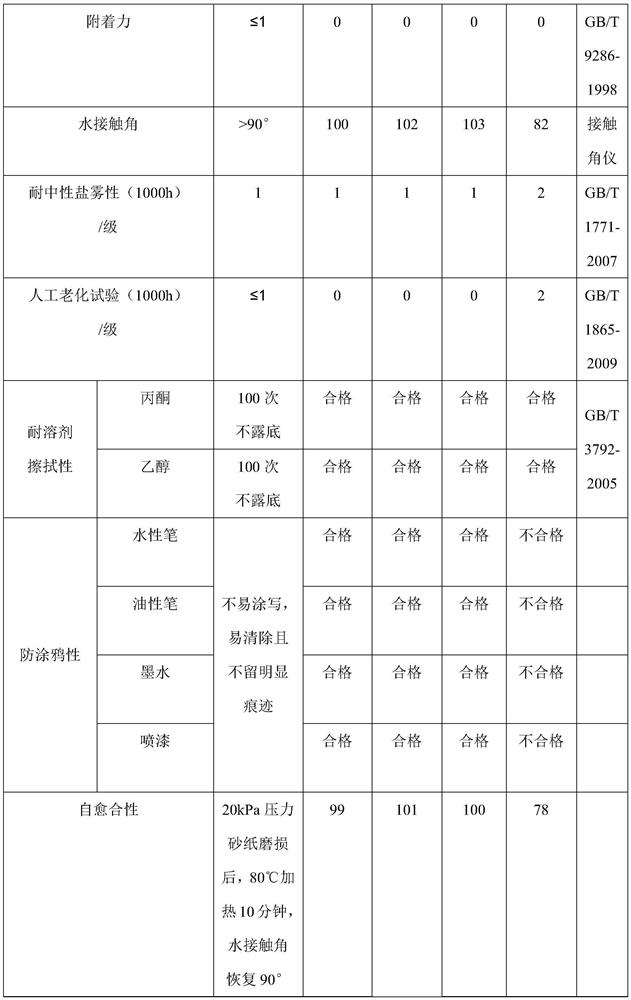

Embodiment 1

[0036](1) First add 100mL ethanol and 1.2 parts by mass of tridecafluorooctyltriethoxysilane (the mass volume ratio of fluorosilane to ethanol is 12g / L) into a 250mL beaker, stir well and then add 9 parts by mass of titanium dioxide Nanoparticles and 0.6 parts by mass of ammonia water (mass fraction: 28%) were sonicated for 10 minutes, stirred and reacted at a temperature of 60° C. for 24 hours, washed and dried to obtain modified titanium dioxide nanoparticles.

[0037] (2) Dissolve 4 parts by mass of isophorone diisocyanate, 7 parts by mass of polyethylene glycol (molecular weight: 400g / mol) and 8 parts by mass of hydroxyl-terminated fluorine-containing silicone oil (molecular weight: 1000g / mol) in 10 parts by mass A homogeneous mixed solution was obtained in acetone and 0.2 parts by mass of dibutyltin dilaurate was added, and after stirring and reacting at 60°C for 4 hours, the temperature was slowly lowered to 40°C, and then 5 parts by mass of pentaerythritol triacrylate, 0...

Embodiment 2

[0040] (1) First add 130mL tetrahydrofuran and 1.5 parts by mass of heptadecafluorodecyltrimethoxysilane (the mass volume ratio of fluorosilane to tetrahydrofuran is 11.5g / L) into a 250mL beaker, stir well and then add 8 parts by mass of Silicon oxide nanoparticles and 1 mass part of ammonia water (mass fraction: 28%) were sonicated for 10 minutes, stirred and reacted at a temperature of 65° C. for 24 hours, washed and dried to obtain modified silica nanoparticles.

[0041] (2) Dissolve 2 parts by mass of hexamethylene diisocyanate, 9 parts by mass of polycarbonate diol (molecular weight: 1000g / mol) and 6 parts by mass of hydroxyl-terminated fluorosilicone oil (molecular weight: 2000g / mol) in 20 mass parts 0.2 parts by mass of pentamethyldiethylenetriamine was added to obtain a uniform mixed solution in 4 parts of tetrahydrofuran, and after stirring and reacting at 60°C for 5 hours, the temperature was slowly lowered to 40°C, and 4 parts by mass of dipentaerythritol pentaacryla...

Embodiment 3

[0044] (1) First add 120mL butyl acetate and 2 parts by mass of dodecafluoroheptylpropyltrimethoxysilane (the mass volume ratio of fluorosilane to butyl acetate is 16.7g / L) into a 250mL beaker, stir well Then add 10 parts by mass of zirconia nanoparticles and 1.5 parts by mass of ammonia water (28% by mass), sonicate for 15 minutes, stir and react at a temperature of 65° C. for 24 hours, wash and dry to obtain modified zirconia nanoparticles.

[0045] (2) Dissolve 4.5 parts by mass of hexamethylene diisocyanate, 8 parts by mass of polypropylene glycol (molecular weight: 600g / mol) and 9 parts by mass of hydroxyl-terminated fluorosilicone oil (molecular weight: 1000g / mol) in 15 parts by mass of tetrahydrofuran Obtain a uniform mixed solution and add 0.3 parts by mass of N,N'-lutidine, stir and react at 60°C for 4 hours, then slowly cool down to 40°C, and add 6 parts by mass of -β-hydroxyethyl methacrylate, 0.1 part of hydroquinone as a polymerization inhibitor and 10 parts of te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com