Bio-based degradable polyester resin as well as preparation method and application thereof

A technology for degrading polyester and bio-based, applied in application, food science, chewing gum, etc., can solve the problems of difficult to synthesize degradable elastomers, and the types need to be further expanded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

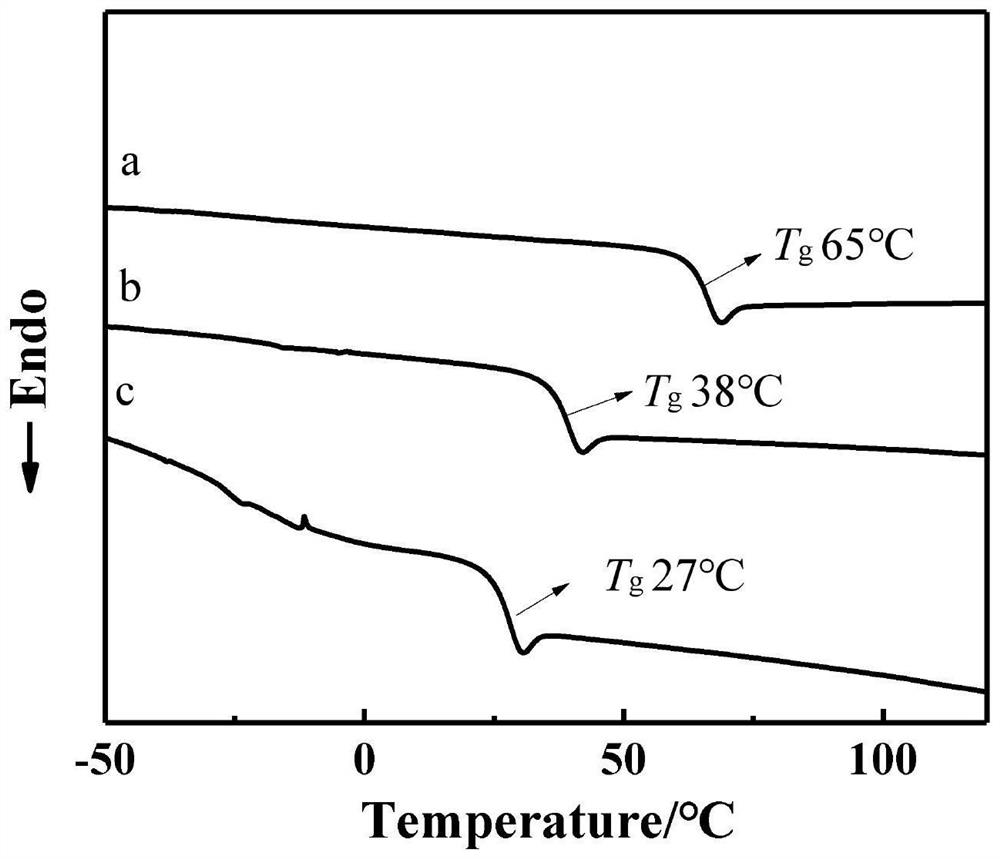

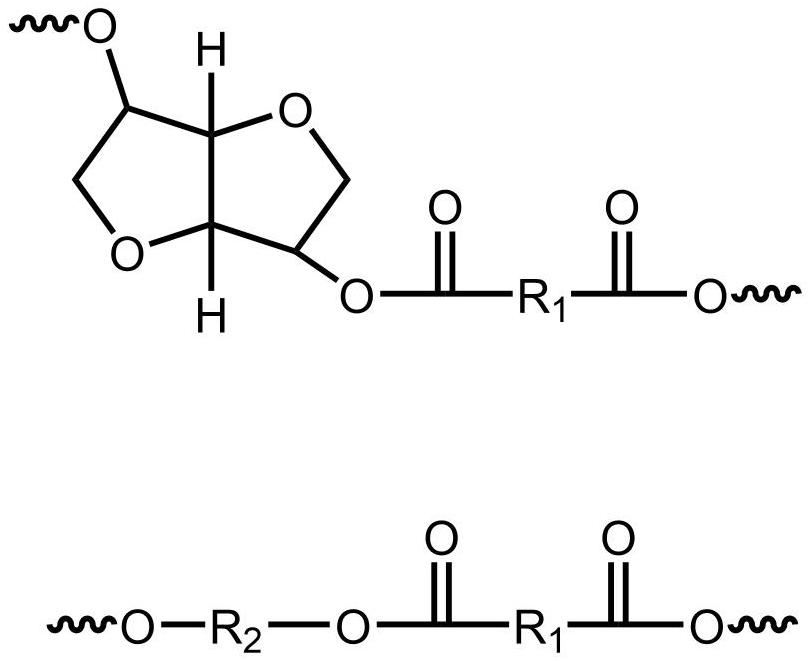

[0039] Get 34.58g of isosorbide, 9.14g of 2,3-butanediol and 36.28g of succinic acid into a 100ml four-neck flask, then heat up to 170°C, 2 Under the reaction, the esterification reaction was carried out for 1h. When it is cooled to room temperature, add 420 μL of 100 g / L tetrabutyl titanate / 1,4-butanediol mixed solution, then raise the temperature to 190°C, and perform esterification for 2 hours to obtain a polyester prepolymer; continue to heat up to 240°C, conduct polycondensation reaction under vacuum for 16 hours, remove water and some small molecules, pass N 2 Cool to 60°C and take out. The resulting bio-based degradable polyester resin contains the following repeating units:

[0040]

Embodiment 2

[0042] Get 25.92g of isosorbide, 15.99g of 2,3-butanediol and 38.10g of succinic acid into a 100ml four-neck flask, then heat up to 170°C, 2 Under the reaction for 1h, carry out the esterification reaction. When it is cooled to room temperature, add 420 μL of 100 g / L tetrabutyl titanate / 1,4-butanediol mixed solution, then raise the temperature to 190°C, and perform esterification for 2 hours to obtain a polyester prepolymer; then raise the temperature to 220°C, react it in a vacuum state for 8h, remove water and some small molecules, pass N 2 Cool to 60°C and take out. The resulting bio-based degradable polyester resin contains the following repeating units:

[0043]

Embodiment 3

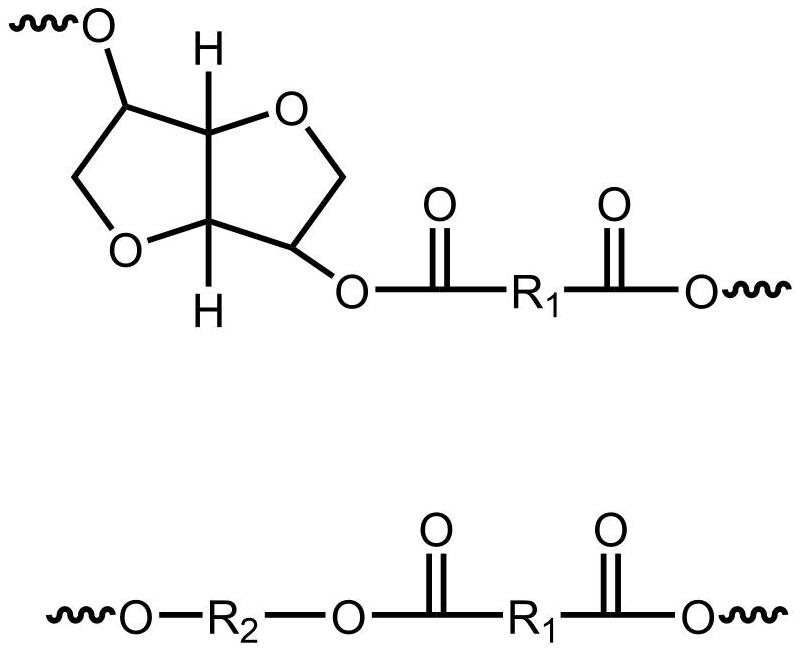

[0045] Get 13.50g of isosorbide, 5.73g of ethylene glycol, 17.96g of 2,3-butanediol and 42.8g of succinic acid into a 100ml four-necked flask, then heat up to 150°C, 2 The reaction was carried out for 1 h, and the esterification reaction was carried out. When it was cooled to room temperature, 420 μL of 100 g / L tetrabutyl titanate / 1,4-butanediol mixed solution was added, and the temperature was raised to 190° C., and the esterification reaction was carried out for 2 h to obtain Polyester prepolymer; then raise the temperature to 220°C, react it in a vacuum state for 6h, remove water and some small molecules, pass N 2 Cool to 60°C and take out. The resulting bio-based degradable polyester resin contains the following repeating units:

[0046]

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com