Preparation method and application of visible light responsive organic-inorganic hybrid membrane

A technology of hybrid film and visible light, applied in chemical instruments and methods, botanical equipment and methods, catalyst activation/preparation, etc., can solve the problems of low catalytic activity and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] As mentioned above, the first aspect of the present invention provides a method for preparing a visible light-responsive organic-inorganic hybrid film, comprising the following steps:

[0025] (1) Silver nitrate solution and polyurethane are contacted and mixed I to dissolve, and mixed solution I is obtained, and the concentration of the silver nitrate solution is 0.05-0.20mol / L;

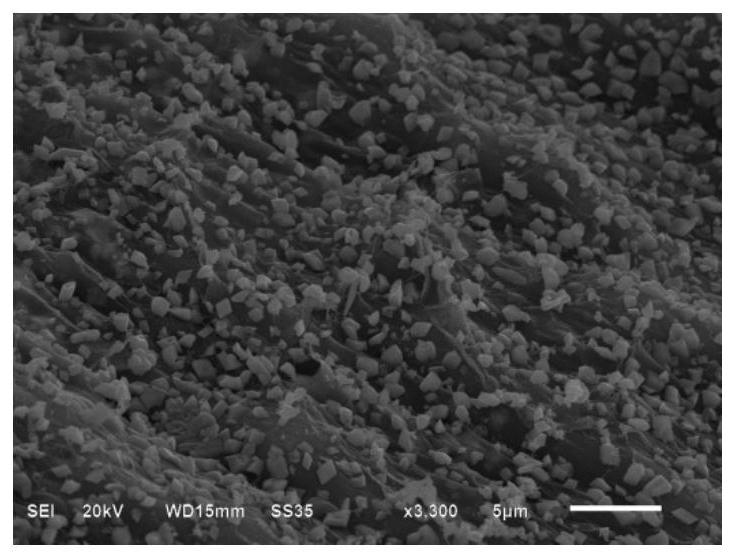

[0026] (2) The mixed solution I is contacted with sepiolite and cerium oxide to obtain a coating solution, the sepiolite is a sepiolite powder with an average particle diameter of 1-3 μm, and the cerium oxide is an average particle diameter Cerium oxide powder of 2-5 μm;

[0027] (3) Apply the coating solution on the substrate to obtain a substrate coated with the coating solution, and after an interval of 0-3 minutes, contact the substrate coated with the coating solution with the YX solution reaction to obtain a hybrid film deposited with in-situ-generated AgX nanoparticles, wherein X is s...

Embodiment 1

[0084] A method for preparing an organic-inorganic hybrid film responsive to visible light, comprising the following steps:

[0085] (1) 65 ml of silver nitrate solution with a concentration of 0.08 mol / L was contacted with 7 g of polyurethane I, and magnetically stirred (350 rpm) for 24 hours at room temperature and protected from light, and polyurethane I was completely dissolved to obtain mixed solution I.

[0086] (2) Put the mixed liquid I in contact with 2g of sepiolite powder I first, add 10g of cerium oxide powder I after the first stirring (350rpm) for 10min, then continue the second stirring (350rpm) for 15min, and let it stand for defoaming After 3 hours, a coating solution was obtained.

[0087] (3) Coating the coating solution on a glass plate (the thickness of the coating solution is 80 μm), and immersing the glass plate coated with the coating solution in 520 mL of 0.01 mol / L potassium chloride solution within 0 minutes After 8 hours of contact reaction, a hybr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com