High-strength manganese oxide granular catalyst and preparation process thereof

A granular catalyst and preparation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, dispersed particle separation, etc., can solve problems such as catalyst low-temperature poisoning failure, low-temperature flue gas denitrification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

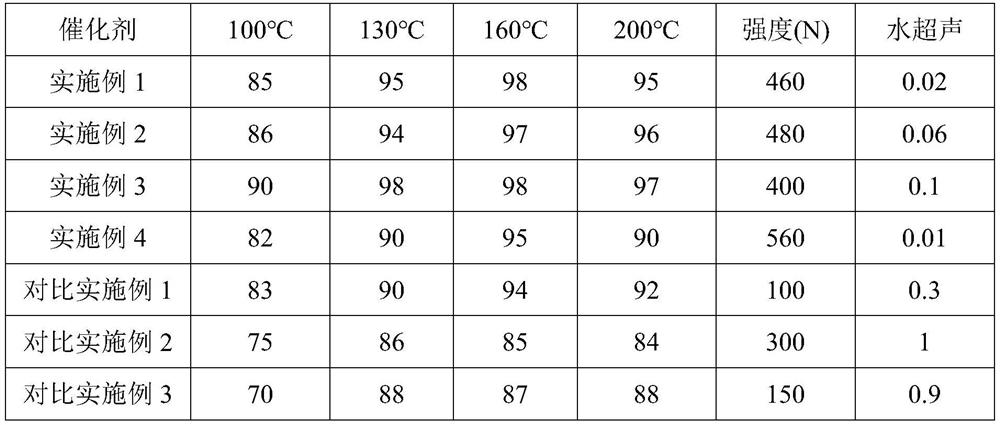

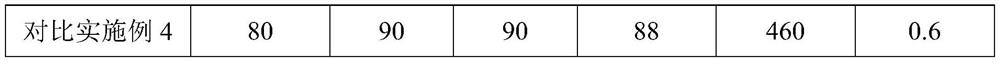

Examples

Embodiment 1

[0032] (1) Take each raw material according to the proportioning ratio, wherein, the quality of manganese carbonate is 500kg, the secondary particle diameter of the manganese carbonate is less than 10 μm, and the surface area is more than 50 μm 2 / g, sulfate radical content in manganese carbonate <1wt%, alkali and alkaline earth metal oxide content <1wt%; Clay is kaolin, quality is 50kg; 30% silica sol quality is 100kg; Organic binder is hydroxypropyl carboxymethyl The base cellulose has a mass of 10 kg; and the inorganic fiber is 30 kg of alkali-free glass fiber chopped strands, with a diameter of 15-30 μm and a length of 3-7 mm.

[0033] (2) Place the above-mentioned manganese carbonate powder and clay raw meal powder weighed in a high-speed mixer, add water and mix at a high speed to obtain a relatively uniform material;

[0034] (3) The above-mentioned obtained material is joined in a strong kneader, and an inorganic binder, an organic binder, and inorganic fibers are adde...

Embodiment 2

[0040] (1) Take each raw material according to the proportioning ratio, wherein the manganese carbonate quality is 300kg, the manganese carbonate secondary particle size is less than 10 μm, and the surface area is more than 50 μm 2 / g, sulfate radical content in manganese carbonate <1wt%, alkali and alkaline earth metal oxide content <1wt%; clay is montmorillonite, quality is 200kg; 30% aluminum sol quality is 150kg; Organic binder is polyvinyl alcohol , the mass is 10 kg; and the inorganic fiber is 10 kg of aluminum silicate fiber, the diameter is 15-30 μm, and the length is 3-7 mm.

[0041] (2) Place the above-mentioned manganese carbonate powder and clay raw meal powder weighed in a high-speed mixer, add water and mix at a high speed to obtain a relatively uniform material;

[0042] (3) the above-mentioned obtained material is joined in a strong kneader, and an organic binder and glass fibers are added to carry out strong kneading to form manganese carbonate mud;

[0043] ...

Embodiment 3

[0048] (1) Take each raw material according to the proportioning ratio, wherein the manganese carbonate quality is 400kg, the manganese carbonate secondary particle size is less than 10 μm, and the surface area is more than 50 μm 2 / g, sulfate radical content<1wt% in manganese carbonate, alkali and alkaline earth metal oxide content<1wt%; Clay is sepiolite, and quality is 150kg; 40% silica sol quality is 150kg; Organic binder is field fine powder , the mass is 15 kg; and the inorganic fiber is 10 kg of alumina fiber, the diameter is 15-30 μm, and the length is 3-7 mm.

[0049] (2) Place the above-mentioned manganese carbonate powder and clay raw meal powder weighed in a high-speed mixer, add water and mix at a high speed to obtain a relatively uniform material;

[0050] (3) the above-mentioned obtained material is joined in a strong kneader, and an organic binder and glass fibers are added to carry out strong kneading to form manganese carbonate mud;

[0051] (4) Put the mang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com