Quartz sand filter material with excellent oleophylic and hydrophobic properties and preparation method thereof

A quartz sand, hydrophobic technology, applied in the field of quartz sand, can solve the problems of difficult oily wastewater and discharge up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

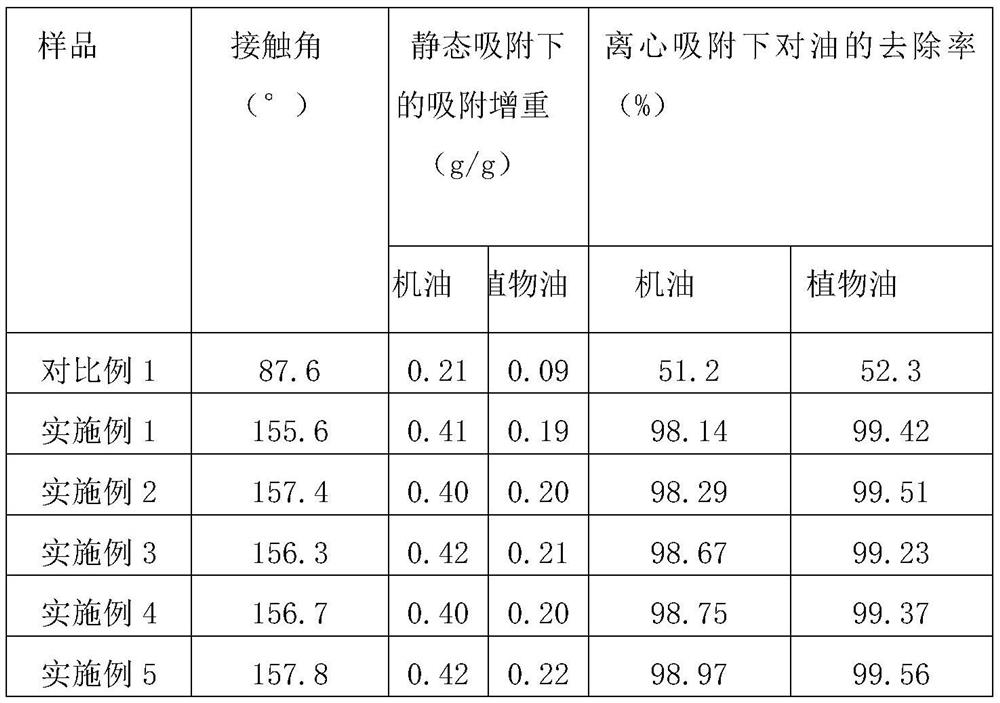

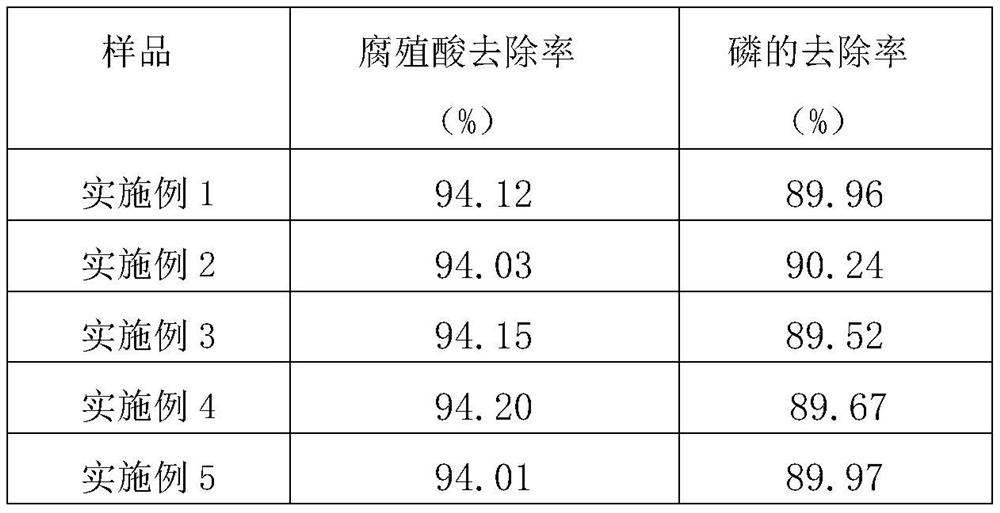

Examples

Embodiment 1

[0038] (1) Pretreatment of quartz sand: Use a 20-30 mesh stainless steel sieve to screen out quartz sand with a particle size of 0.55-0.83mm, wash it repeatedly with deionized water until it is no longer turbid, and then put it in a vacuum drying oven at 110°C Dry for 12 hours; after cooling, soak the quartz sand in 1mol / L nitric acid solution for 20 hours, then soak it in absolute ethanol for 30 minutes, and finally wash and dry it for use; (2) surface modification: according to the formula, the The surface modification liquid, in parts by mass, mainly consists of the following components: 395 parts of absolute ethanol, 25 parts of tris(hydroxymethyl)aminomethane, 1.58 parts of nano-zinc oxide, 0.0025 parts of dopamine hydrochloride; Methyl) aminomethane is dissolved in dehydrated alcohol, obtains the ethanol solution of tris (hydroxymethyl) aminomethane, then nanometer zinc oxide, dopamine hydrochloride are added in the ethanol solution of above-mentioned tris (hydroxymethyl)...

Embodiment 2

[0042] (1) Pretreatment of quartz sand: Use a 20-30 mesh stainless steel sieve to screen out quartz sand with a particle size of 0.55-0.83mm, wash it repeatedly with deionized water until it is no longer turbid, and then put it in a vacuum drying oven at 100°C Dry for 10 hours; after cooling, soak the quartz sand in 1mol / L nitric acid solution for 20 hours, then soak in absolute ethanol for 30 minutes, and finally wash and dry for use;

[0043] (2) Surface modification: According to the formula, the surface modification liquid is mainly composed of the following components in parts by mass: 395 parts of absolute ethanol, 28 parts of tris(hydroxymethyl)aminomethane, nano 1.59 parts of zinc oxide, 0.003 part of dopamine hydrochloride; tris(hydroxymethyl)aminomethane is dissolved in absolute ethanol to obtain an ethanol solution of tris(hydroxymethyl)aminomethane, and then nanometer zinc oxide and dopamine hydrochloride are added to the three (Hydroxymethyl) aminomethane is disso...

Embodiment 3

[0047] (1) Pretreatment of quartz sand: Use a 20-30 mesh stainless steel sieve to screen out quartz sand with a particle size of 0.55-0.83mm, wash it repeatedly with deionized water until it is no longer turbid, and then put it in a vacuum drying oven at 100°C Dry for 12 hours; after cooling, soak the quartz sand in 1mol / L nitric acid solution for 22 hours, then soak in absolute ethanol for 30 minutes, and finally wash and dry for use;

[0048] (2) Surface modification: According to the formula, the surface modification liquid is mainly composed of the following components in parts by mass: 395 parts of absolute ethanol, 25 parts of tris(hydroxymethyl)aminomethane, nano 1.54 parts of zinc oxide, 0.0028 parts of dopamine hydrochloride; tris(hydroxymethyl)aminomethane is dissolved in absolute ethanol to obtain an ethanol solution of tris(hydroxymethyl)aminomethane, and then nanometer zinc oxide and dopamine hydrochloride are added to the three (Hydroxymethyl) aminomethane is dis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com